MYWAY Bushing: Automotive Transmission System Dual Mass Flywheel Bushing Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Automotive » Automotive Transmission System Dual Mass Flywheel Bushings

MYWAY Automotive Transmission Dual Mass Flywheel Bushing

Automotive Transmission System Dual Mass Flywheel

Automotive Transmission System Dual Mass Flywheel

Automotive Transmission System Dual Mass Flywheel

Mini Model Valeo Solid Flywheel Conversion For 2002-2008 Mini Cooper - Replaces Dual Mass Flywheel Auto Model

Automotive Transmission System Dual Mass Flywheel

Uxcell 8mm X 12mm X 20mm Sleeve Bearings Square Flanged

BUSHING, STEERING KNUCKLE (0311276080)

1000+ Types of Transmission Dual Mass Flywheel Bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

|---|---|---|

| Automotive Transmission System | Dual Mass Flywheel | PTFE Self-Lubricating Bushing |

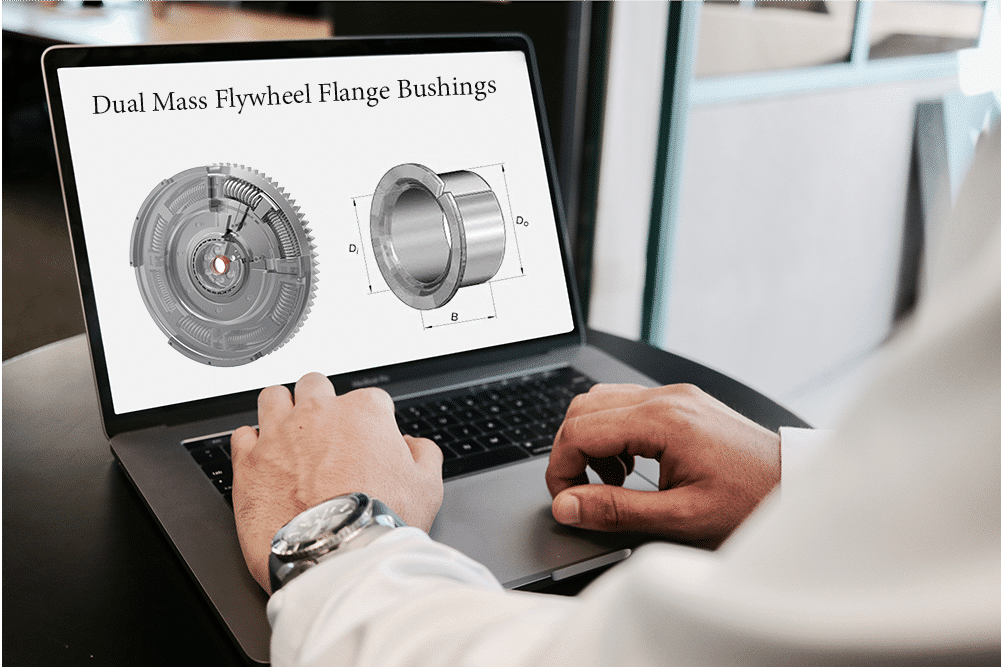

Dual Mass Flywheel Bushings: The Silent Hero for Smoother Transmissions

Ever wondered what makes the gear shifts in modern manual cars so much smoother and quieter than in older models? Or why that annoying cabin vibration has disappeared, especially in diesel and high-torque vehicles? A significant part of the credit goes to an ingenious component called the Dual Mass Flywheel (DMF), and at the heart of its operation is a critical, yet often overlooked part: the DMF bushing.

This article dives deep into the world of automotive transmission systems, focusing on the pivotal role of the dual mass flywheel bushing. We’ll explain how it works, why its material matters, and how choosing the right one can be a game-changer for performance and durability. Finally, we’ll introduce you to how MYWAY, as a precision manufacturing expert, delivers bushing solutions that meet the highest demands of the global automotive industry.

Understanding the Dual Mass Flywheel (DMF): Why Your Car Needs One

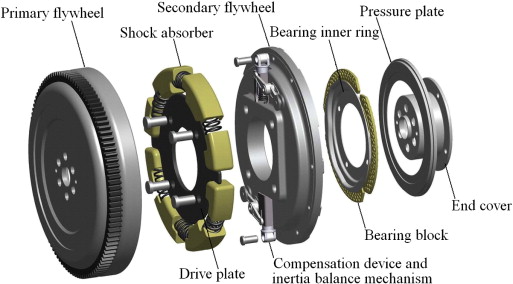

First, let’s break down the basics. A flywheel is a heavy disc attached to the end of your engine’s crankshaft. Its primary job is to store rotational energy, smoothing out the engine’s power pulses. A traditional single mass flywheel (SMF) is just that—a single, solid piece of metal.

However, modern engines, particularly diesel and high-torque petrol engines, produce significant torsional vibrations. These are twisting forces that pulse through the drivetrain. A single mass flywheel transmits these vibrations directly to the gearbox, leading to:

Noisy, clunky gear changes

Increased wear on transmission components

Unpleasant cabin vibration (especially at low RPM)

The dreaded “gear rattle” when idling in neutral

Enter the Dual Mass Flywheel. As the name suggests, it splits the single mass into two:

Primary Mass: Attached directly to the crankshaft.

Secondary Mass: Connected to the clutch and gearbox input shaft.

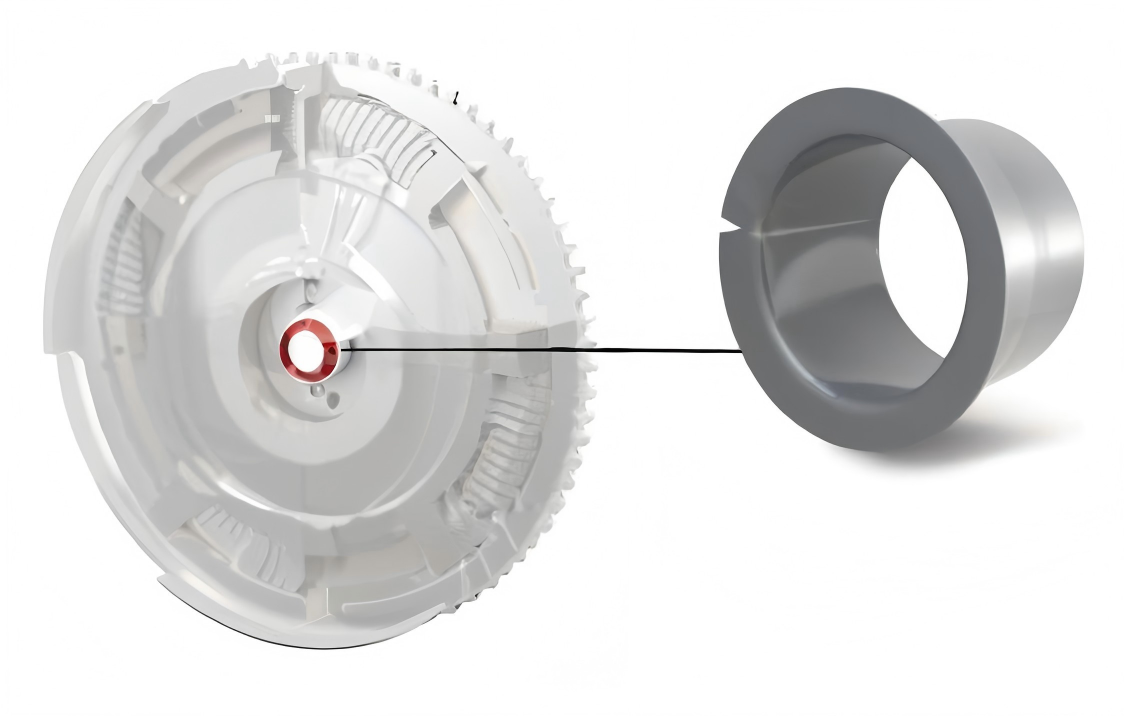

These two masses are linked not rigidly, but through a damping system of arc springs and, crucially, an interface component that allows them to rotate independently. This interface is where the bearing or bushing comes in.

The Critical Interface: Bearing vs. Bushing Technology

The connection between the primary and secondary masses is what defines the DMF’s performance. There are two main technologies:

Traditional Bearing Design: Uses a rolling-element bearing. It’s precise but has limited angular tolerance.

Advanced Bushing Design: Uses a plain bearing (bushing). This is where innovation shines.

The DMF bushing is a sleeve that allows the two flywheels to rotate relative to each other with minimal friction. The key advantage? It allows for a much greater controlled angular movement (or “tilt”)—typically up to 2.6mm compared to about 1.2mm for a bearing design. This greater damping capacity is why more and more vehicle manufacturers are adopting bushing technology in their DMFs for superior Noise, Vibration, and Harshness (NVH) reduction.

What Makes a High-Performance DMF Bushing? The Material Science

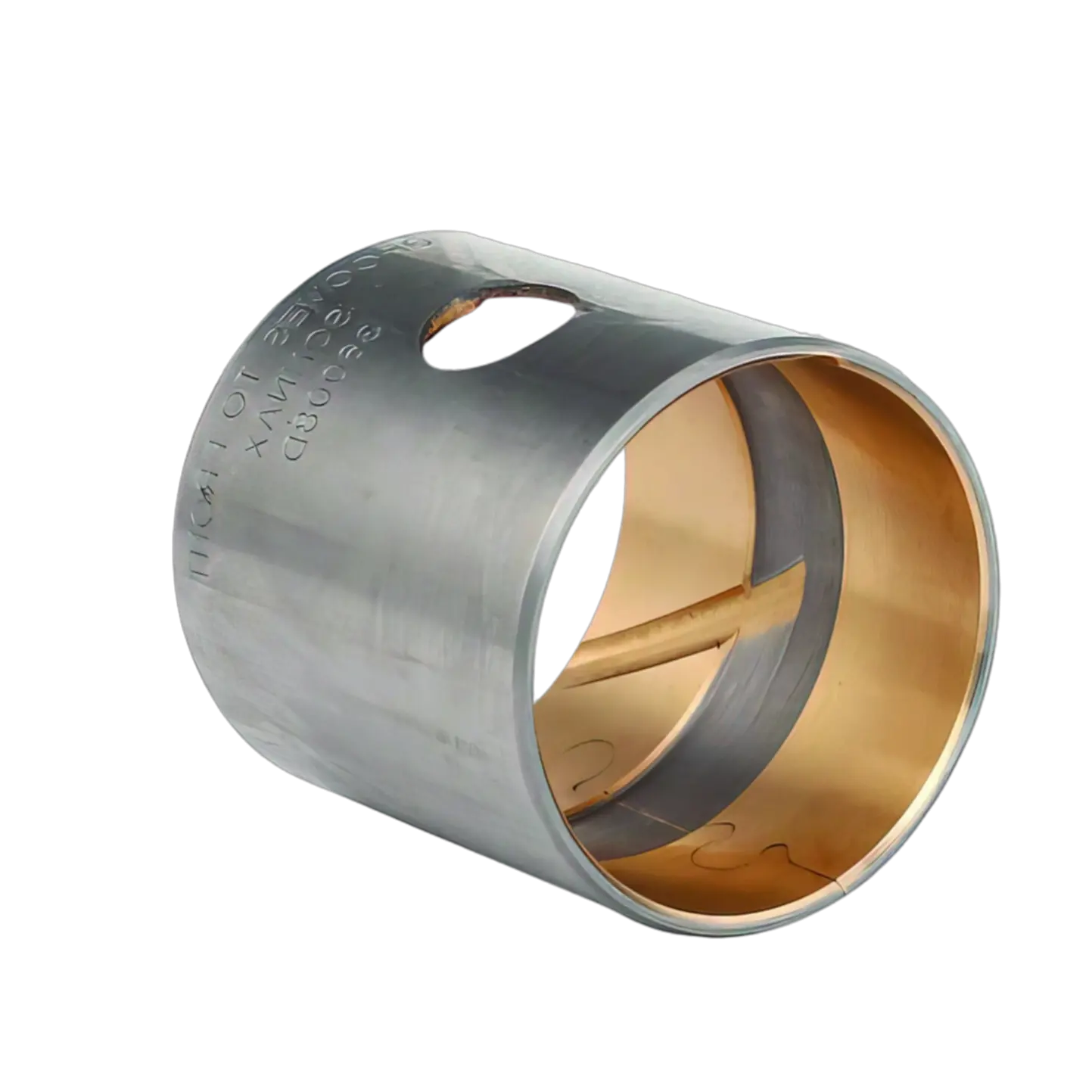

Not all bushings are created equal. The demanding environment of a DMF—high loads, varying temperatures, and continuous oscillation—requires an engineered material solution. The industry standard for top-tier performance is a composite, self-lubricating bushing, typically with a three-layer structure:

| Layer | Material | Primary Function |

|---|---|---|

| Backing Layer | High-Strength Steel (or Bronze for corrosion resistance) | Provides structural integrity, handles high loads, and ensures a secure press-fit into the flywheel. |

| Intermediate Layer | Sintered Porous Bronze | Bonded to the backing, it acts as a reservoir for the lubricant and provides a robust, wear-resistant substrate. |

| Working Surface | PTFE (Polytetrafluoroethylene)-Based Composite | This is the magic layer. It offers an extremely low coefficient of friction, is self-lubricating, and provides excellent wear resistance over the bushing’s entire lifespan. |

Why PTFE is a Game-Changer for DMF Bushings

Integrating a PTFE composite liner transforms bushing performance:

Maintenance-Free Operation: The PTFE layer continuously transfers lubricant, eliminating the need for external grease points or service.

Exceptional Dry-Running Capability: Functions perfectly even if external lubrication fails temporarily.

Dampens Vibration: The polymer structure helps absorb high-frequency vibrations, contributing to a quieter drivetrain.

Handles Contamination: Unlike rolling bearings, plain bushings are less susceptible to failure from minor dust or debris.

The MYWAY Advantage: Precision Engineered for Demanding Applications

At MYWAY, we understand that a DMF bushing isn’t just a commodity part; it’s a critical wear component that directly impacts driving comfort and transmission longevity. Our expertise in high-precision, high-volume manufacturing for global leaders in construction and automotive sectors translates directly into our automotive bushing solutions.

Why Partner with MYWAY for Your DMF Bushing Needs?

Deep Material and Process Expertise: We don’t just machine parts; we engineer solutions. Our team can guide material selection—from standard steel-backed PTFE composites to specialized bronze-backed versions for unique corrosion or thermal conductivity needs. We control the process from material sintering to final precision machining.

Proven Manufacturing Scale and Quality: With an annual casting capacity of 35,000 tons and a track record of supplying over 300 major companies like XCMG, SANY, and Great Wall Motors (GWM), our systems are built for both quality consistency and volume scalability. Our operations adhere to stringent IATF 16949-aligned quality standards.

Full Customization & Engineering Support: Need a specific flange diameter, a unique oil groove pattern, or a custom straight bushing size? We provide custom-engineered solutions. Our engineers can work with your designs or help develop a bushing that optimizes performance for your specific DMF application, whether for passenger cars, heavy-duty trucks, or performance vehicles.

A Partner You Can Trust: Our core philosophy—“Quality is our lifeline, credibility drives our growth”—is reflected in everything we do. We offer more than just parts; we offer reliable partnership, transparent communication, and a commitment to being a long-term, value-adding supplier to your business.

Ready to experience the MYWAY difference in your transmission system?

If you are designing a new DMF, looking for a more reliable second-source supplier, or need a high-performance replacement bushing solution, MYWAY has the technical capability and manufacturing muscle to deliver.

👉 Contact the MYWAY team today for a technical consultation or to request a sample. Let’s discuss how our precision dual mass flywheel bushings can enhance your product’s performance, durability, and value.

FAQ: Dual Mass Flywheel (DMF) Bushings

Q1: What’s the main difference between a DMF with a bearing and one with a bushing?

A: The core difference is in the interface technology and tolerance. A bearing-based DMF uses rolling elements (like ball bearings) and allows for limited angular movement (~1.2mm tilt). A bushing-based DMF uses a sliding-contact plain bearing, which allows for significantly greater controlled angular movement (up to ~2.6mm tilt). This enhanced damping capacity makes bushing designs superior for maximizing NVH reduction in modern, refined vehicles.

Q2: Are self-lubricating PTFE bushings really maintenance-free for the life of the vehicle?

A: In a properly designed and manufactured DMF system, yes. High-quality PTFE composite bushings are engineered to be maintenance-free. The PTFE-based lining provides a continuous, low-friction sliding surface throughout its designed service life, which often matches or exceeds the lifespan of the clutch assembly itself. There is no need for external lubrication.

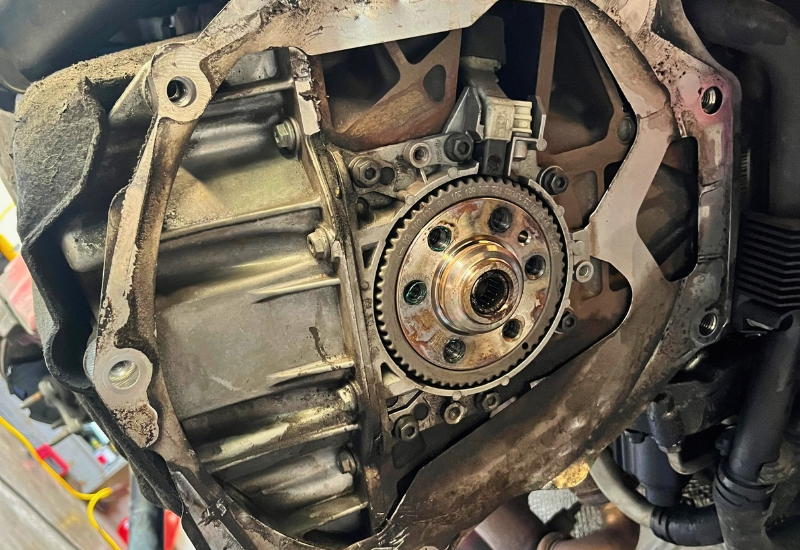

Q3: When should a DMF bushing be replaced?

A: The DMF bushing is an integral part of the flywheel assembly. Industry best practice strongly recommends inspecting and typically replacing the entire DMF unit whenever the clutch is replaced. Signs of a failing DMF (which could be due to spring or bushing wear) include excessive vibration (especially at idle), loud rattling noises from the bellhousing that disappear when the clutch is depressed, and rough gear engagement. Replacing the DMF with the clutch avoids costly double labor charges.

Q4: Can MYWAY produce bushings for both original equipment (OE) and aftermarket replacement?

A: Absolutely. MYWAY’s manufacturing flexibility allows us to serve both markets. We can produce OE-spec bushings that match original design parameters exactly. For the independent aftermarket (IAM), we provide high-quality replacement solutions, including comprehensive repair kits that ensure a perfect fit and restored performance. We also offer custom flange and straight bushing designs to meet specific aftermarket needs.

Q5: My application involves high torque or modified engines. Are standard DMF bushings sufficient?

A: High-torque, performance, or towing applications place extreme stress on the drivetrain. While a standard OE-spec bushing might work, it’s an area where engineering consultation is key. MYWAY can discuss material enhancements (like different PTFE filler mixes), optimized wall thickness, or specific groove patterns to handle increased loads and ensure reliability in demanding use cases.