MYWAY Bushing: Automotive Transmission System Gear Shift Fork Bushing Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Automotive » Automotive Transmission System Gear Shift Fork Bushings

MYWAY Automotive Transmission System Gear Shift Fork Bushing

Automotive Transmission System Gear Shift Fork Bushing

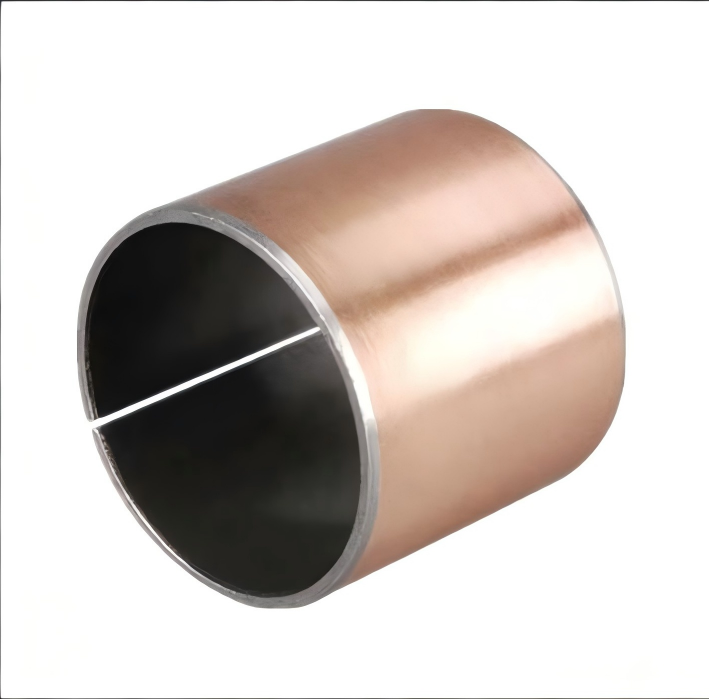

DU/SF-1 Steel-Backed Self-Lubricating Bushing (Black PTFE)

Automotive Transmission System Gear Shift Fork Bushing

DU/SF-1B Bronze-Matrix Self-Lubricating Bushing (Black PTFE)

Automotive Transmission System Gear Shift Fork Bushing

DU/SF-1B Bronze-Matrix Self-Lubricating Bushing (Red PTFE)

Automotive Transmission System Gear Shift Fork Bushing

Self-Lubricating Bushing for Reciprocating Motion (Grey PTFE)

1000+ Types of Automotive Transmission System Gear Shift Fork Bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

|---|---|---|

| Transmission System Component | Shift Fork Bushing | DU/SF-1 Self-Lubricating Bushing |

Smooth Shifting: How the Right Shift Fork Bushing Transmits Performance

From Grinding Gears to Graceful Shifts

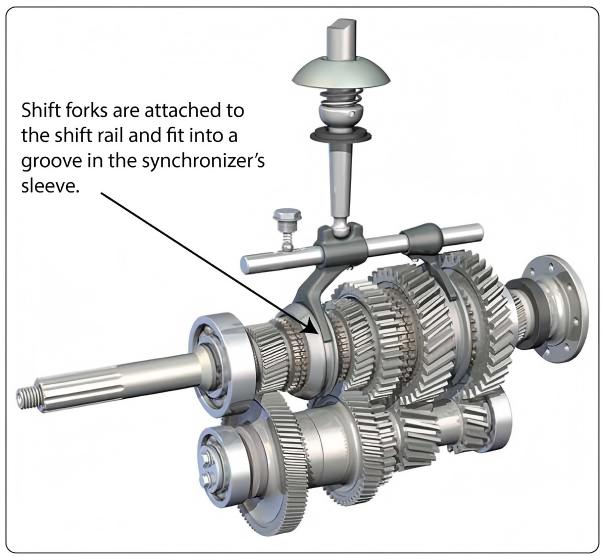

In the world of automotive transmissions, whether manual or automatic, the pursuit of a crisp, precise, and reliable gear change is paramount. This experience hinges on a symphony of moving parts, many of which operate out of sight. Among these, the shift fork plays a starring role as the mechanical hand that physically moves gears or synchronizers into position. Yet, the performance and longevity of this critical component are profoundly dependent on a small, often overlooked part: the shift fork bushing.

This article delves into why the humble bushing is a linchpin for transmission durability and shift quality. We’ll explore the challenges of traditional solutions, the engineering behind modern self-lubricating bushings, and how choosing a technologically advanced partner like MYWAY can safeguard your transmission systems against wear, noise, and premature failure.

The Crucial Role and Inevitable Foe of the Shift Fork Bushing

A shift fork is a highly stressed component. It must withstand constant lateral forces, oscillating movements, and exposure to transmission fluid at varying temperatures. The bushing, typically located where the fork pivots on its shaft or interacts with a selector mechanism, serves a vital purpose:

Providing a Low-Friction Pivot Point: It allows the fork to slide or rotate with minimal resistance, ensuring quick and effortless gear engagement.

Absorbing Vibrations and Impacts: It dampens the mechanical shocks from clutch engagement, engine pulses, and driveline forces.

Maintaining Precise Alignment: It keeps the fork in its correct geometric path, preventing misalignment that leads to partial gear engagement or “gear grind.”

The traditional enemies here are wear and friction. As evidenced in transmission part catalogs and repair manuals, bushings are listed as standard wearable items, indicating their critical yet consumable nature. Over time, friction can wear down a standard bushing, creating excess clearance. This play manifests as imprecise shifts, increased operational noise (like a “clicking” or “slapping” sound during gear changes), and eventually, failure to properly engage gears.

Beyond Traditional Materials: The Rise of Engineered Composites

For decades, solutions ranged from simple oil-impregnated bronze to rubber or plastic bushings. Each has limitations:

Bronze Bushings: Require constant lubrication and can wear the mating shaft.

Polymer Bushings: May deform under high load or in high-temperature transmission environments.

Rubber Bushings: Excellent for vibration damping but introduce unwanted compliance and lag in a system demanding precision.

The modern solution lies in composite, self-lubricating materials. These are engineered to provide the best of all worlds: the strength of metal, the low friction of advanced polymers, and maintenance-free operation.

The DU/SF-1 Bushing: A Three-Layer Masterpiece for Transmission Duty

The DU/SF-1 series bushing represents a pinnacle of this composite design, making it exceptionally suitable for shift fork applications. Its tri-metal structure is a feat of material science:

| Layer | Material | Primary Function in a Shift Fork Application |

|---|---|---|

| Backing Layer | Low-Carbon Steel Strip | Provides high structural strength and secure press-fit into the fork housing, handling the significant lateral thrust loads. |

| Sintered Interlayer | Porous Bronze Matrix | Sintered onto the steel backing, this layer acts as a reservoir for the lubricant and a robust, heat-conducting substrate. |

| Sliding Surface | PTFE (Polytetrafluoroethylene) & Lead Mixture | A thin, impregnated layer that offers an extremely low and consistent coefficient of friction (typically 0.03-0.20), ensuring smooth operation from the first to the millionth shift. |

This design delivers tangible benefits for transmission systems:

Maintenance-Free & Dry-Running: The PTFE-based surface provides built-in lubrication, ideal for areas where consistent oil splash cannot be guaranteed. This significantly reduces the risk of wear-related failure.

High Load Capacity: With a static load capacity up to 250 N/mm², it can handle the high-pressure, low-speed oscillating movements of a shift fork.

Dirt Tolerance: The soft PTFE layer can embed minor contaminants, preventing them from scoring the shaft—a valuable trait in any mechanical system.

Wide Temperature Range: Capable of operating from -195°C to +280°C, it is more than equipped for the thermal environment inside a transmission.

The MYWAY Advantage: Precision Engineered for Demanding Applications

At MYWAY, we understand that a superior component like the DU/SF-1 bushing is only as good as the precision and consistency with which it is manufactured. We transform advanced material science into reliable, high-performance solutions for the global automotive and industrial sectors.

Why MYWAY is Your Ideal Partner for Shift Fork Bushings:

Deep Application Expertise: We don’t just sell bushings; we provide solutions. Our engineering team understands the specific load cycles, environmental conditions, and failure modes within transmission systems. We can guide you on optimal bushing selection, whether it’s a standard SF-1 series or a customized variant for a unique application.

Vertical Manufacturing Integration: We control the entire production process, from the selection of raw steel strip to the precise sintering of the bronze layer and the final curing of the PTFE composite. This ensures uncompromising quality control and traceability for every batch.

Proven Scale and Reliability: With an annual production capacity in the millions of pieces and a track record of supplying demanding industries, our systems are built for both high-volume consistency and the flexibility to meet specialized, just-in-time requirements.

Commitment to Partnership: Our philosophy—”Quality is our lifeline, credibility drives our growth”—means we engage as a technical partner. We are committed to providing not just parts, but the support and collaboration needed to ensure your transmission designs achieve their full potential for smoothness, durability, and performance.

Ready to eliminate shift fork wear as a failure point in your designs?

Contact the MYWAY engineering team today. Let’s discuss how our precision DU/SF-1 self-lubricating bushings can enhance the shift quality, longevity, and reliability of your transmission systems.

FAQ: Shift Fork Bushings and DU/SF-1 Solutions

Q1: My design uses a traditional bronze bushing. Why should I switch to a DU/SF-1 composite bushing?

A: The key advantages are maintenance-free operation and consistent performance over time. Bronze bushings require continuous lubrication and can wear both themselves and the mating shaft. The PTFE surface of a DU bushing provides its own lubrication, drastically reducing wear on both the bushing and the shaft, leading to longer system life and more consistent shift feel.

Q2: Can DU/SF-1 bushings handle the high-impact loads during a aggressive gear shift?

A: Yes. While they excel in high-load, low-speed oscillating applications (perfect for shift fork motion), their robust steel backing gives them high static load capacity (up to 250 N/mm²). This makes them well-suited to withstand the shock loads encountered during rapid gear engagement.

Q3: Are these bushings suitable for both manual and automatic transmissions?

A: Absolutely. In manual transmissions, they are ideal for shift fork pivot points and selector shaft supports. In automatics, they are used within the valve body for selector levers, detent arms, or any other low-speed oscillating pivot that requires precise, low-friction movement without constant external lubrication.

Q4: How does MYWAY ensure consistency in such a complex layered product?

A: Quality is engineered into every step. We employ strict process controls for each layer: the steel backing’s thickness and preparation, the sintering temperature and density of the bronze matrix, and the precise composition and curing of the PTFE overlay. Rigorous batch testing ensures every bushing meets our specified performance parameters for dimensions, bond strength, and friction characteristics.

Q5: We have a unique space constraint or performance requirement. Can the DU/SF-1 be customized?

A: Yes. The SF-1 series offers versatility. While the standard product has a steel backing, variations are available with a bronze backing (SF-1B) for enhanced corrosion resistance or different plating options. Our engineering team can work with you on custom geometries, specific wall thicknesses, or tailored PTFE blend formulations to meet unique application challenges.