MYWAY Reliable Bronze Bushings

Self-lubricating, Corrosion-resistant and High Rigidity

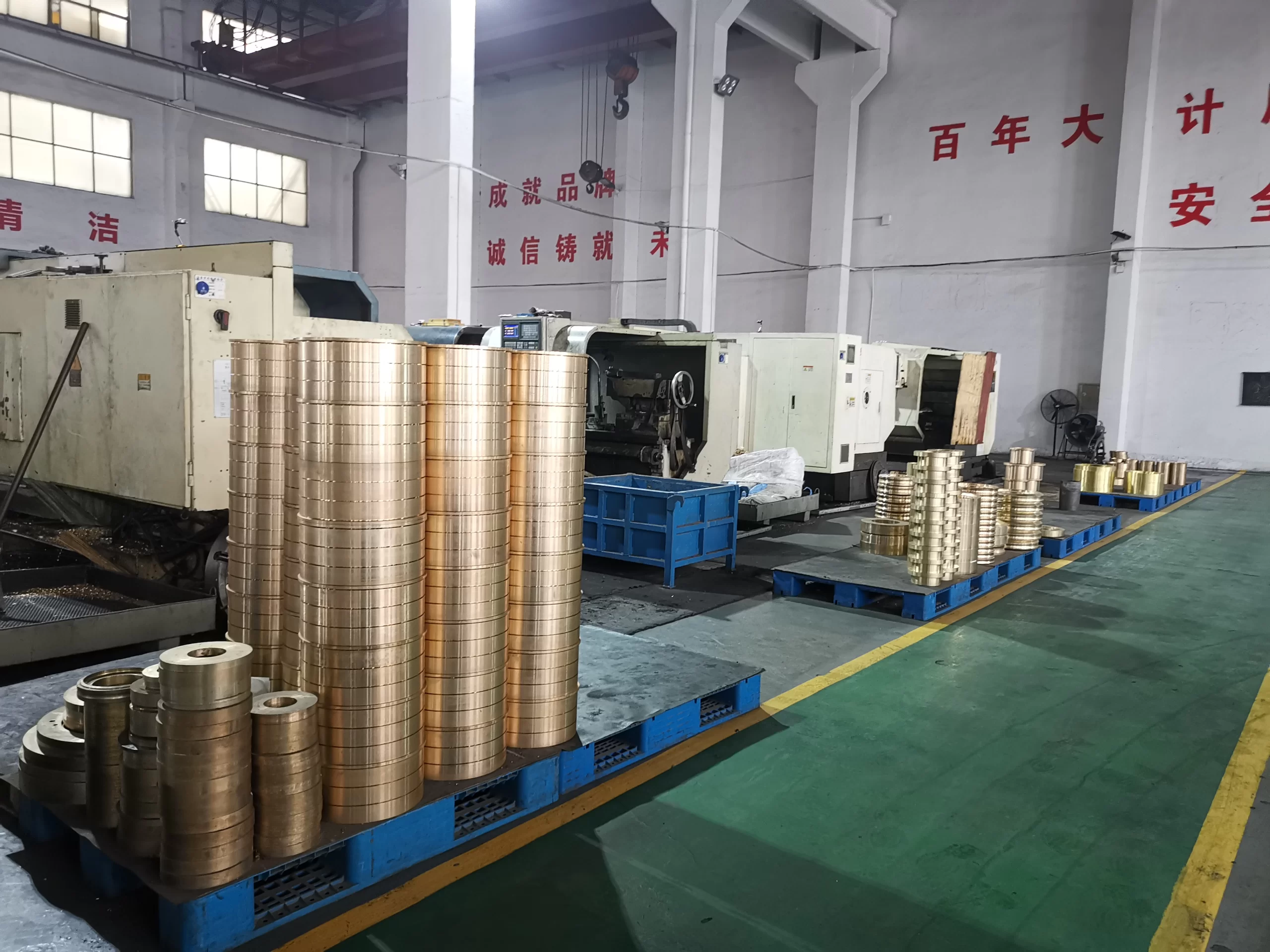

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Bronze Bushing

Bronze Bushing

What is Bronze Bushing?

MYWAY Bronze Bushing Series are newly improved copper alloy products independently cast and precision-machined by our company. These bronze bushings deliver exceptionally high strength and hardness, excellent wear and corrosion resistance, high pressure tolerance, as well as superior machinability and castability, making them ideal for demanding industrial applications.

Bronze Bushings by Structure

Bronze Bushings by Metallographic

Bronze Bushings by Material

Bronze Bushings by Appearance

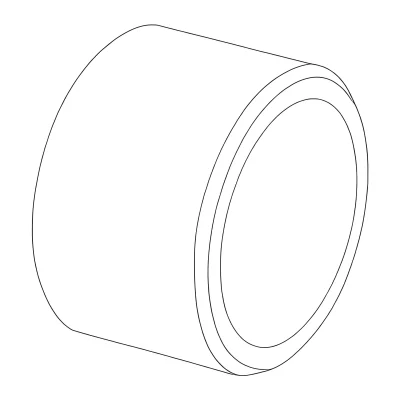

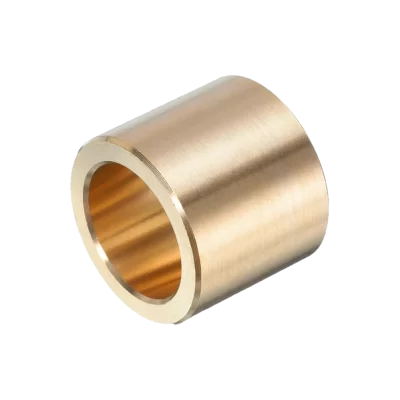

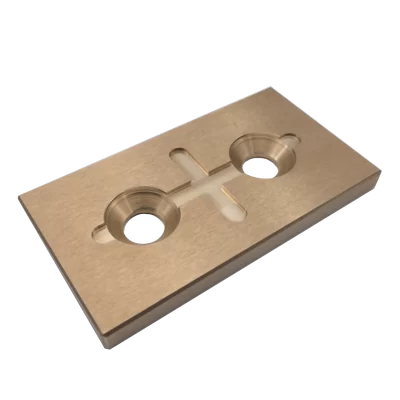

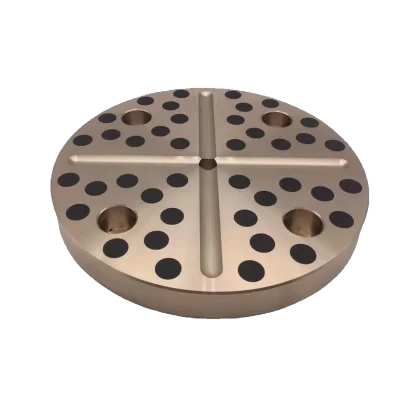

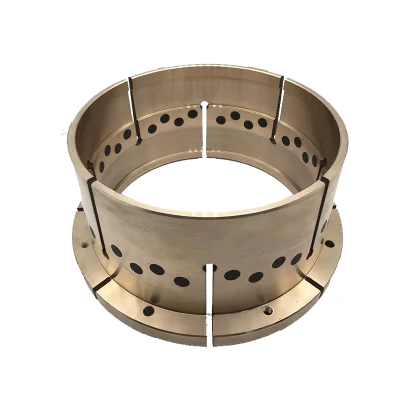

Plain - Bronze Bushings

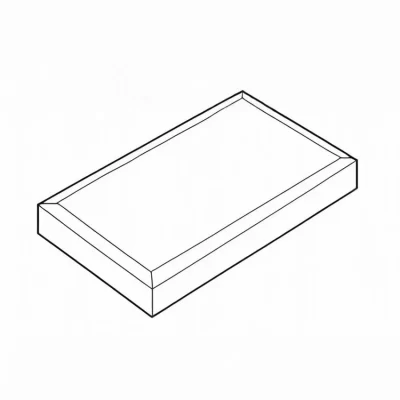

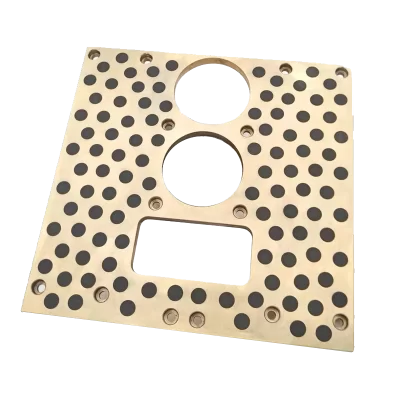

Wear Plates - Bronze Bushings

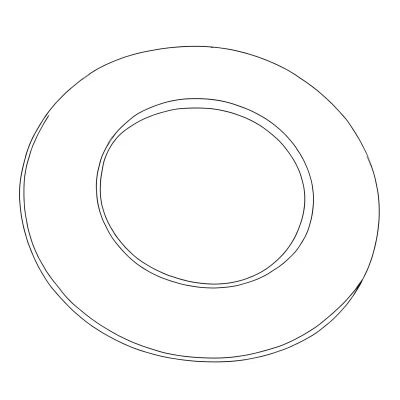

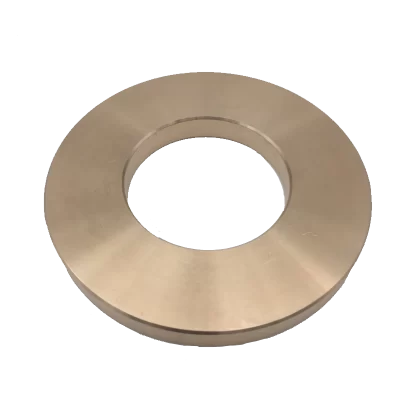

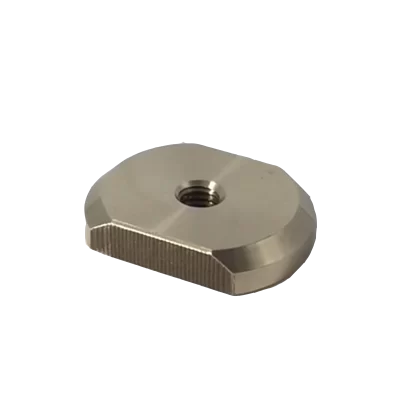

Trust Washer - Bronze Bushings

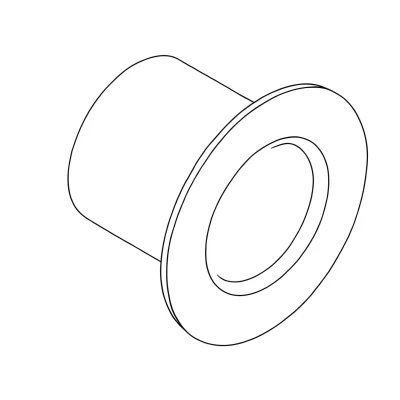

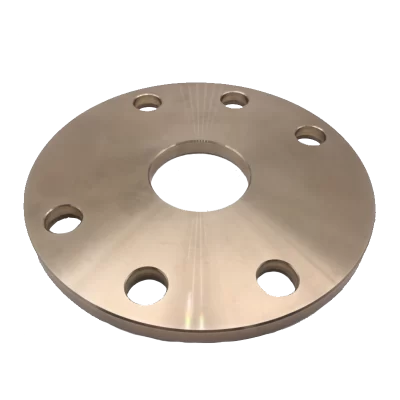

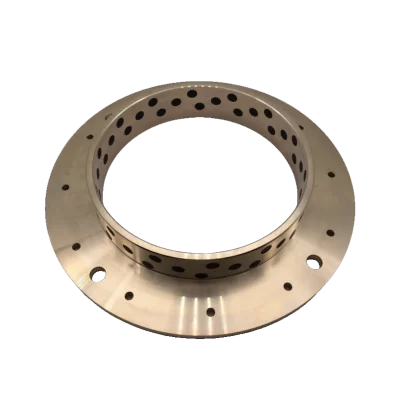

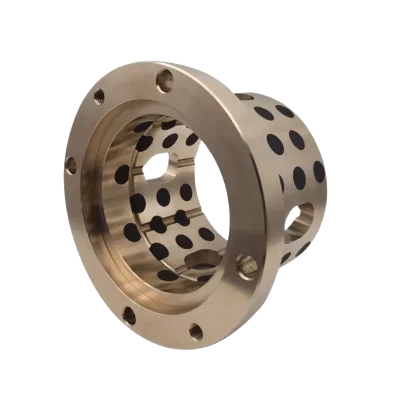

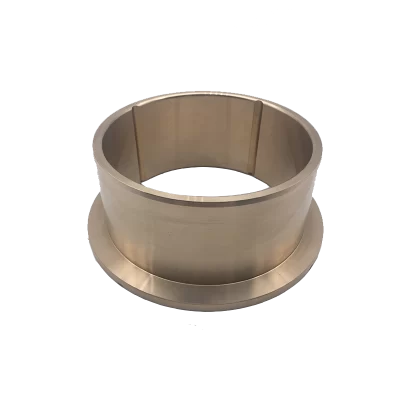

Flange - Bronze Bushings

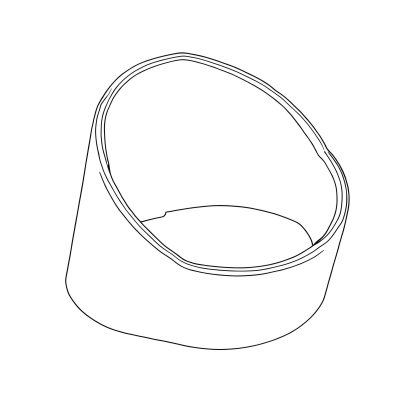

Special Shape - Bronze Bushings

Bronze Bushings by Structure

Bronze Bushings by Graphite Color

Bronze Bushings by Size

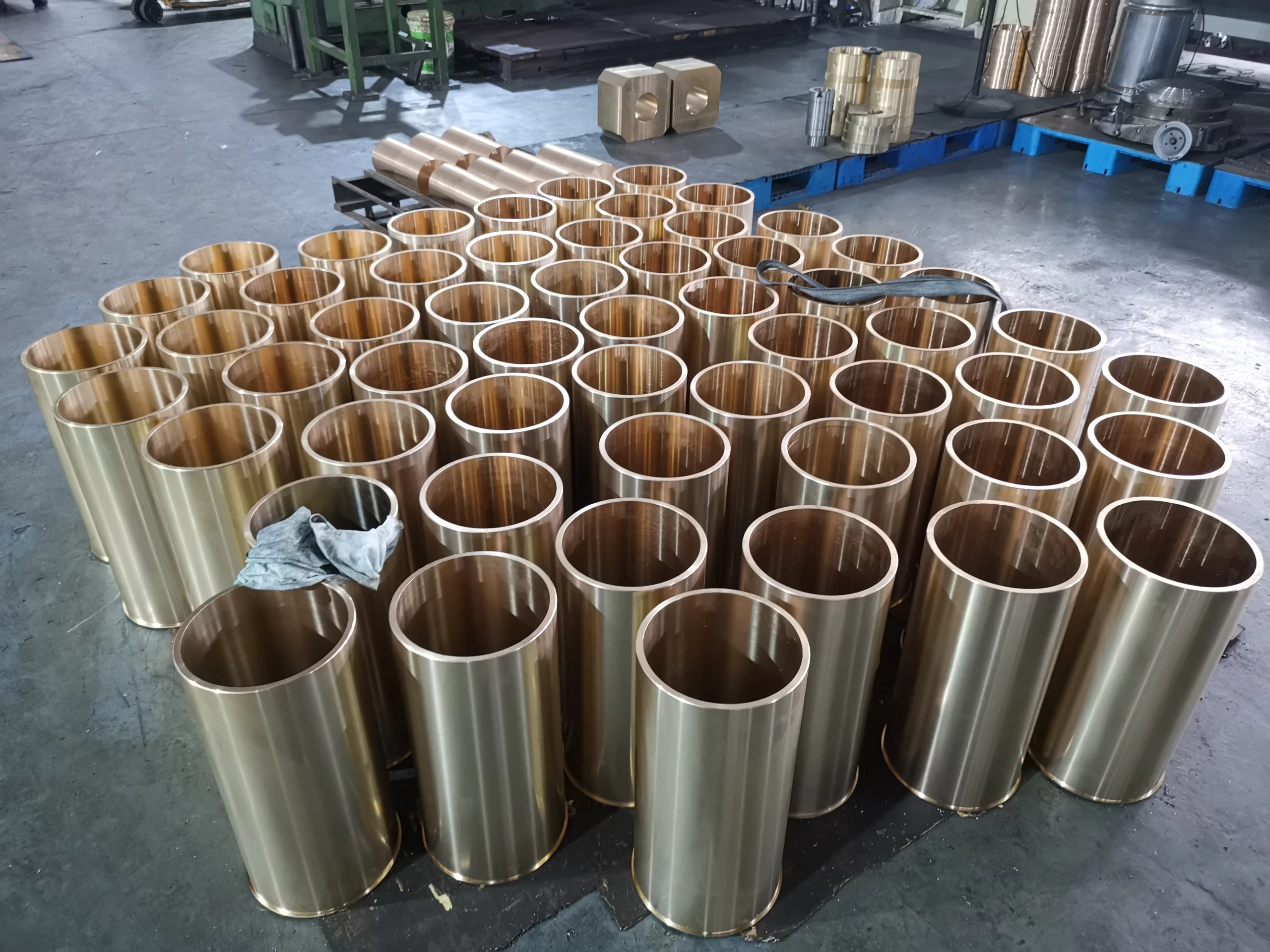

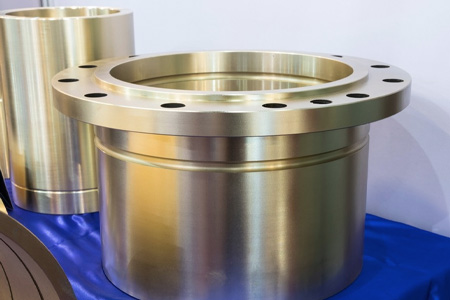

Large Bronze Bushings

Specialized for heavy equipment applications like construction equipment, hydroelectric power, crushers, offshore vessels, etc., large bronze bushings are available up to 20 inches in diameter.

Small Bronze Bushings

The inside diameter of miniature bronze bushings is typically less than 2 inches. They are commonly used for precision machinery or small equipment, with excellent strength and wear resistance.

Thin Bronze Bushings

The preferred material for thin walled bronze bushings is aluminum bronze with high strength and low density of 7.45 g/cm³. The bushings have a wall thickness of less than 2 mm.

Bronze Bushings by Type

Applications of Self Lubricating Bushing

Our Factory

At MYWAY, we produce bronze bushings from smelting high-purity copper alloys to finished products. Our manufacturing process utilizes precision centrifugal casting to ensure uniform density and structural integrity, followed by CNC machining that achieves micron-level accuracy. Automated polishing and robotic assembly lines maintain consistent quality, while CMM and optical inspection systems verify every product’s specifications. This complete vertical integration enables MYWAY to deliver bronze bushings that meet the most demanding industrial requirements.

Brass Bushings vs. Bronze Bushings

Bronze and brass are both copper alloys and are commonly used raw materials for bushings. However, their composition and characteristics are different. The following is a comparison between the two. You can choose the material that suits you according to your needs.

- Composition: Bronze is a copper alloy that usually contains tin, aluminum or other metal elements. Brass is an alloy of copper and zinc.

- Hardness: In comparison, bronze bushings have higher strength and hardness, while brass bushings are softer and easier to process and install.

- Corrosion Resistance: Brass bushings are often used for general purposes, such as mildly corrosive environments in non-marine applications; while bronze is suitable for harsh environments, including marine, chemical or high-temperature applications.

Economic Cost: Brass bushings are usually cheaper than bronze bushings and are an economical and effective choice.

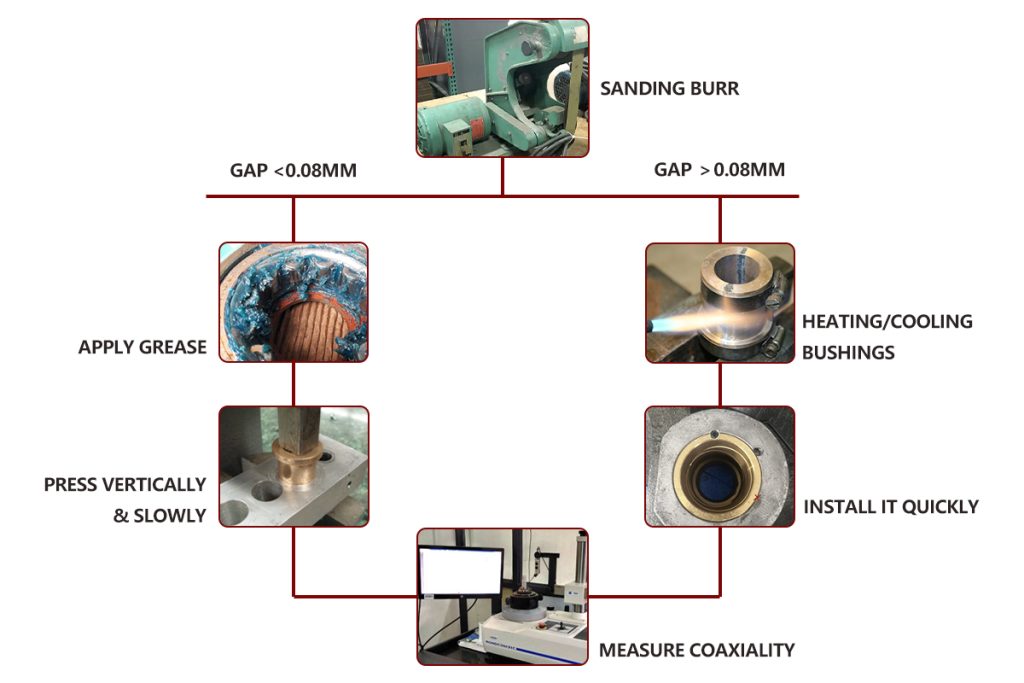

How to Install Bronze Bushings

Strictly comply with the process specifications and correctly install or move the bronze bushing to ensure the reliability and service life of your equipment to the maximum.

- Preparation: First, you need to confirm that the interference between the outer diameter of the bushing and the inner diameter of the mounting hole is 0.04~0.10mm, grind burrs to Ra≤6μm, align oil holes, and ready tools/grease.

- Core Steps of Installation: If your interference is ≤0.08mm, you can apply grease and press vertically and slowly; however, if the interference is greater than 0.08mm or it is a high-precision scene, you need to heat the mounting hole to 80~120℃ to expand it by 0.05~0.10mm and then install the bushing, or cool the bushing to shrink its outer diameter by 0.03~0.06mm and then install it quickly.

- Inspection: Measure coaxiality (≤02mm), run no-load 15-30 mins (monitor temp rise≤20℃/noise), then test 50%-75%-100% loads (1hr each, check temp/vibration every 15 mins).

MYWAY Bronze Bushings: Your Ultimate Guide to High-Performance Sintered & Cast Bronze Bearings

Introduction: The Power of Bronze in Industrial Applications

Bronze bushings represent the gold standard in bearing technology, offering exceptional durability and reliability across countless industrial applications. As a leading manufacturer of bronze sleeve bushings and self-lubricating bearings, MYWAY combines ancient metallurgical wisdom with modern engineering to deliver solutions that withstand extreme conditions while minimizing maintenance requirements.

Why Choose Bronze Over Other Materials?

Bronze vs. Brass Bushings: Understanding the Difference

While both bronze and brass belong to the “red metals” family, they serve distinctly different purposes in industrial applications:

Bronze Bushings: Superior hardness and strength, excellent wear resistance, minimal deformation under pressure

Brass Bushings: Softer material, more prone to deformation and breakage, suitable for lighter applications

Key Advantages of MYWAY Bronze Bushings:

Exceptional mechanical strength and durability

Superior corrosion resistance in harsh environments

Excellent wear resistance under heavy loads

Low friction coefficients for smoother operation

High load capacity and impact resistance

Wide temperature range compatibility

Cost-effective, sustainable solution (100% recyclable)

MYWAY Bronze Bushing Product Lines

1. Standard Bronze Bushings (C93200/SAE 660)

Our standard inventory includes C93200 bronze sleeve bearings featuring:

81-85% copper composition with 6.3-7.5% tin

Excellent machinability and wear resistance

Immediate availability for quick delivery

Perfect for general industrial applications

2. Specialized Bronze Alloys

We offer comprehensive material options to meet specific requirements:

Tin Bronze Alloys: Optimal strength for heavy-load applications

Leaded Tin Bronze: Enhanced antifriction properties and machinability

High Leaded Tin Bronze: Superior lubrication capabilities

Aluminum Bronze: Exceptional strength and seawater corrosion resistance

Manganese Bronze: High-strength solution for demanding environments

Phosphor Bronze: Excellent toughness and low friction

Silicon Bronze: High-temperature performance

Nickel Aluminum Bronze: Maximum corrosion resistance

3. Manufacturing Processes: Sintered vs. Cast Bronze

Sintered Bronze Bushings:

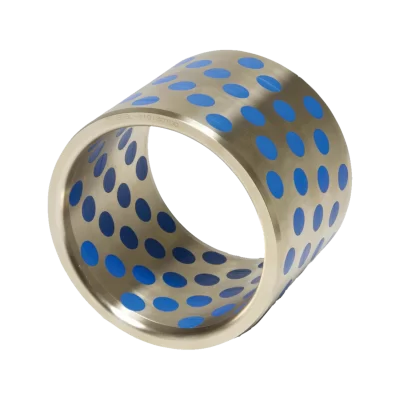

Porous bronze matrix structure

Self-lubricating capabilities

Ideal for high and low-speed applications

Wide temperature range operation

Maintenance-free operation

Cast Bronze Bushings:

Superior mechanical strength

Enhanced corrosion resistance

Perfect for wet environments

Excellent for heavy-duty applications

Long-lasting performance

Comprehensive Bushing Types & Configurations

1. Cylindrical/Sleeve Bearings

Standard plain bronze bushings

Oil-impregnated bronze bushings

Graphite plugged bronze bushings

Applications: High-load, high-temperature environments

Single and double flanged bronze bushings

Built-in bearing housing units

Ideal for light to medium duty applications

Common in conveyor systems and food processing equipment

Bronze thrust washers for rotational applications

Easy assembly and disassembly

High load capacity in harsh environments

Widely used in automotive and aerospace industries

Industry Applications & Success Stories

MYWAY bronze bushings serve critical functions across diverse sectors:

Aerospace: Flight control systems, landing gear assemblies

Automotive: Sway bars, control arms, suspension components

Heavy Equipment: Construction and mining machinery

Marine & Offshore: Steering mechanisms, propulsion systems

Energy Sector: Wind turbine gearboxes, hydroelectric turbines

Industrial Machinery: Pumps, compressors, conveyor systems

Steel Manufacturing: High-temperature applications

Food Processing: Corrosion-resistant equipment

Technical Selection Guide

Critical Selection Factors:

Load Conditions: Dynamic and static loading requirements

Operating Speed: RPM and surface speed considerations

Environmental Factors: Temperature, moisture, chemical exposure

Space Constraints: Installation dimensions and wall thickness

Movement Type: Rotary, oscillating, or linear motion patterns

Material Selection Guide:

High Load Applications: C95400, C86300 manganese bronze

Corrosive Environments: Aluminum bronze, nickel aluminum bronze

General Purpose: C93200 bearing bronze

High Temperature: Silicon bronze alloys

Marine Applications: Aluminum bronze series

Installation & Maintenance Best Practices

Proper Installation Procedures:

Ensure correct housing dimensions and surface finish

Maintain proper press-fit tolerances

Verify alignment during assembly

Use appropriate installation tools

Lubrication Requirements:

While some sintered bronze bushings offer self-lubricating properties, most bronze bearings require proper lubrication:

Reduces friction and wear

Prevents corrosion

Extends service life

Improves operational efficiency

Maintenance Guidelines:

Regular visual inspections for wear patterns

Monitor operating temperatures

Check for unusual noise or vibration

Maintain lubrication schedules

Keep records of service life and performance

Why Choose MYWAY Bronze Bushings?

Technical Excellence:

Comprehensive alloy selection for optimal performance

Advanced manufacturing capabilities (sintering and casting)

Precision engineering and tight tolerances

Rigorous quality control and testing

Customer Benefits:

Reduced total cost of ownership

Extended equipment lifespan

Minimal maintenance requirements

Custom engineering solutions

Global supply chain reliability

Competitive pricing

REQUEST YOUR CUSTOM BRONZE BUSHING QUOTE

Ready to enhance your equipment’s performance with reliable bronze bushings? Contact MYWAY’s engineering team today for:

Application-specific product recommendations

Custom design and manufacturing services

Competitive pricing and delivery information

Technical support and engineering consultation

Explore our complete bronze bushing catalog and technical resources

MYWAY Bronze Solutions: Engineered for Performance, Built for Reliability

MYWAY Bronze Bushing FAQs

1. Do bronze bushings need grease?

The lubrication requirements for bronze bushings depend on the specific type:

Oil-impregnated bronze bushings and graphite-plugged bronze bushings are designed for self-lubricating, maintenance-free operation

Standard sintered bronze bushings and cast bronze bushings typically require external lubrication (grease or oil) for optimal performance

Proper lubrication reduces friction, minimizes wear, prevents corrosion, and extends service life

MYWAY provides specific lubrication recommendations based on your application requirements

2. How to install bronze bushings properly?

Follow these key steps for correct bronze bushing installation:

Ensure housing and shaft are clean and free of contaminants

Verify proper dimensional tolerances before installation

Use appropriate press-fit tools and equipment

Apply even pressure during installation to prevent distortion

Check alignment after installation

For flanged bronze bushings, ensure proper seating against the housing

Lubricate according to manufacturer specifications (unless using self-lubricating types)

3. How to remove bronze bushings safely?

Safe removal of bronze bushings requires careful technique:

Use specialized bearing pullers or extraction tools

Apply heat carefully if necessary (avoid overheating)

Press out using hydraulic or mechanical presses

For damaged bushings, consider cutting carefully with a rotary tool

Always wear appropriate safety equipment

Preserve the housing integrity during removal

4. What are bronze bushings used for?

Bronze bushings serve critical roles across numerous industries:

Automotive applications: Suspension systems, steering components, sway bars

Industrial machinery: Pumps, compressors, conveyor systems

Heavy equipment: Construction and mining machinery

Marine applications: Steering mechanisms, propulsion systems

Aerospace: Landing gear assemblies, flight control systems

Energy sector: Wind turbines, hydroelectric power plants

They’re ideal for high-load, low-speed applications requiring durability

5. Why is bronze used for bushings?

Bronze offers unique advantages that make it ideal for bushing applications:

Excellent wear resistance and durability

High load-bearing capacity

Good corrosion resistance

Low friction coefficients

Thermal conductivity for heat dissipation

Compatibility with various lubricants

Machinability for precision applications

Long service life in demanding conditions

5. A bronze bushing is mounted inside a steel sleeve - is this configuration common?

Yes, this is a standard and highly effective configuration:

The steel sleeve provides structural strength and support

The bronze bushing offers excellent bearing surfaces

This combination is common in bimetal bearings

Provides the strength of steel with the wear resistance of bronze

Ideal for heavy-duty applications and high-load conditions

MYWAY specializes in both standard and custom bimetal solutions

6. Where to find high-quality bronze bushings?

MYWAY is your trusted source for premium bronze bushings:

We manufacture both standard and custom bronze sleeve bearings

Comprehensive range including sintered bronze, cast bronze, and oil-impregnated types

Available in various alloys: C93200, C95400, C86300, and more

Custom manufacturing to your exact specifications

Strict quality control and performance testing

Competitive pricing and reliable delivery

Technical support and engineering consultation

7. What's the difference between bronze and brass bushings?

Key differences include:

Bronze bushings: Harder, stronger, better wear resistance, suitable for heavy loads

Brass bushings: Softer, more malleable, more likely to deform under pressure

Bronze typically lasts longer in demanding applications

Brass may be suitable for lighter duty, non-critical applications

8. Can bronze bushings be used in high-temperature applications?

Yes, depending on the specific bronze alloy:

Standard bronze bushings: Up to 250°C continuous operation

Special alloys: Can withstand up to 350°C

Aluminum bronze and silicon bronze offer superior high-temperature performance

Consult MYWAY engineers for specific high-temperature applications

9. Are bronze bushings suitable for marine environments?

Absolutely, particularly certain bronze alloys:

Aluminum bronze and nickel aluminum bronze offer excellent seawater corrosion resistance

Ideal for marine applications, offshore equipment, and coastal installations

Provide reliable performance in saltwater conditions

MYWAY can recommend the optimal alloy for your marine application