Recent Posts

Copper, Brass, or Bronze? How to Choosing the Right Bushing Material

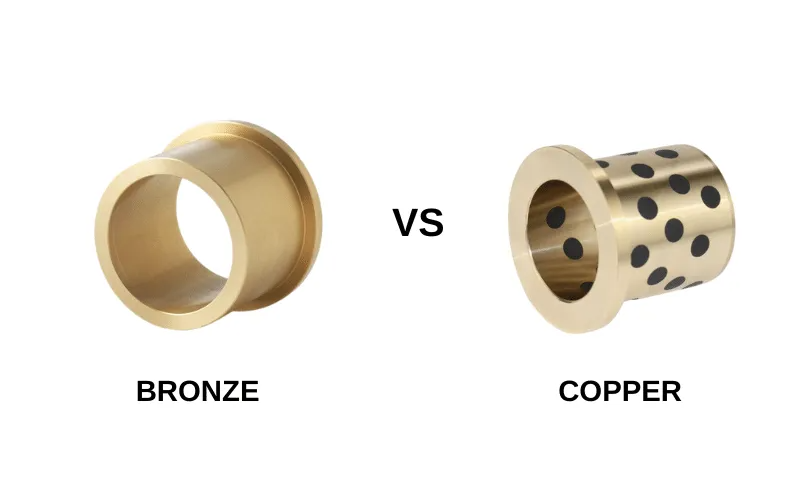

In the world of industrial machinery and heavy equipment, the choice of a bushing material is far from trivial. It’s a critical decision that impacts machine longevity, maintenance costs, and overall operational efficiency. For decades, engineers have turned to copper-based metals for their excellent bearing properties. But with options like copper, brass, and bronze available, how do you choose? This guide cuts through the complexity, comparing these three materials head-to-head and exploring why modern engineering often looks beyond them for the most demanding applications.

Table of Contents

1. The Material Lineup: Defining the Contenders

First, let’s clarify the fundamental differences between these commonly confused metals.

Copper (Cu): This is the pure, base element. It’s known for its excellent electrical and thermal conductivity, good corrosion resistance, and high ductility. However, its relatively low strength and hardness make it soft and prone to deformation under heavy loads, rendering it generally unsuitable for high-stress bushing applications.

Brass: An alloy primarily of copper and zinc (Zn). The addition of zinc increases strength and hardness compared to pure copper. Certain brasses, like free-machining brass (C36000), are prized for their excellent machinability. While brass can serve in light-duty bushings, its wear resistance and load capacity are typically lower than bronze’s. A notable weakness is its susceptibility to dezincification—a corrosive process where zinc leaches out—in certain wet or chemical environments, leaving a porous, weak copper structure behind.

Bronze: Traditionally an alloy of copper and tin (Sn), though modern “bronze” encompasses alloys with aluminum, silicon, or other elements. The addition of tin or aluminum creates a material that is significantly harder, stronger, and more wear-resistant than both copper and most brasses. This superior combination of properties has rightfully earned bronze its title as the traditional “bearing champion” for a vast range of industrial applications.

2. Head-to-Head Comparison: Performance in Bushing Applications

The table below summarizes how these materials stack up in key performance areas critical for bushings and bearings:

| Feature | Copper (Cu) | Brass (Cu-Zn) | Bronze (Cu-Sn/Al) | Implication for Bushings |

|---|---|---|---|---|

| Strength & Hardness | Low | Moderate | High to Very High | Bronze resists deformation and indentation under heavy loads. |

| Wear Resistance | Poor | Fair | Excellent | CRITICAL: Bronze provides a much longer service life in sliding contact, reducing downtime. |

| Corrosion Resistance | Good (forms patina) | Good (but risk of dezincification) | Very Good to Excellent | Bronze, especially aluminum or tin bronzes, often outperforms in harsh/marine environments. |

| Machinability | Fair (can be gummy) | Excellent (e.g., C36000) | Fair to Good (varies by alloy) | Brass is easiest to machine for simple parts, but advanced machining can handle bronze for complex designs. |

| Key Advantage | Thermal/Electrical Conductivity | Cost & Machinability | Overall Bearing Performance | For durability and load, bronze is the clear winner among traditional metals. |

Beyond the basics, modern research shows that the performance of both copper and brass can be significantly enhanced through advanced processing techniques like Severe Plastic Deformation (SPD). These methods refine the metal’s grain structure to the nanometer scale, dramatically increasing hardness and wear resistance. However, such specialized processing underscores a key point: achieving optimal bearing properties often requires moving beyond standard, off-the-shelf materials.

3. The Modern Evolution: Why Composite Materials Are Taking Over

Table 3: Sealing Options and Performance Characteristics

While bronze remains a robust choice, the frontier of bushing technology has evolved to solve its remaining limitations: the constant need for external lubrication, performance limits under extreme loads, and friction-induced energy loss.

The answer lies in engineered self-lubricating composite materials. These are not simple alloys, but sophisticated, multi-layered systems designed to outperform homogeneous metals. A leading design, exemplified by MYWAY’s technology, typically features three bonded layers:

A Steel Backing: Provides extremely high structural strength and load capacity, far surpassing traditional bronze.

A Porous Bronze Interlayer: Sintered onto the steel, this layer ensures superior heat dissipation and creates a robust matrix for the final layer.

A PTFE/Polymide Sliding Layer: This top surface embeds solid lubricants (like PTFE) within a high-strength polymer. During operation, a microscopic transfer film coats the mating shaft, creating an ultra-low-friction interface that operates maintenance-free.

This composite approach delivers what single metals cannot: the load capacity of steel, the thermal management of bronze, and the near-frictionless operation of advanced polymers.

4. The MYWAY Advantage: Engineered for Heavy-Duty Performance

At MYWAY, we don’t just supply parts; we provide engineered solutions. Our bushings and thrust washers are designed for industries where failure is not an option—such as heavy-duty trucking, wind turbine gearboxes, and mining equipment.

Proven in Demanding Fields: Our collaboration with leading wind turbine gearbox manufacturers is a testament to this. We developed specialized high-performance components that enable technological breakthroughs like “sliding-over-rolling” designs, significantly enhancing gearbox reliability in both onshore and offshore applications.

Beyond the Wind Industry: The principles of superior load handling, minimal maintenance, and extended life are universal. Our components are engineered to minimize unplanned downtime, extend service intervals, and reduce the total cost of ownership for any dynamic, heavily loaded application.

5. Conclusion: Making the Strategic Choice

The journey from soft copper to versatile brass, and then to durable bronze, charts the history of engineering’s quest for better bearing materials. Today, that journey reaches a new peak with self-lubricating metal-polymer composites.

Choosing a bushing material is no longer just about selecting a metal from a catalog. It’s a strategic decision about operational reliability and cost efficiency. While brass offers machinability and bronze offers solid traditional performance, MYWAY’s composite solutions are engineered to solve the modern challenges of maximum uptime, zero maintenance, and extreme durability.

Ready to specify a component that outperforms traditional materials?

Contact the MYWAY engineering team today for a consultation. Let us analyze your application and show you how our precision-engineered bushings and thrust washers can become the most reliable, cost-saving component in your machine.

Frequently Asked Questions (FAQ)

Q: My current design uses bronze bushings. Can I directly replace them with MYWAY composites?

A: In most cases, yes. MYWAY composite bushings are often designed as drop-in replacements for standard bronze sizes. Our engineering team can provide specific guidance based on your operating conditions (load, speed, temperature) to ensure optimal performance.

Q: Are self-lubricating composites suitable for high-temperature applications?

A: Yes, but within specified ranges. Standard PTFE-based composites perform reliably up to approx. 280°C (536°F). For extreme temperatures, we offer specialized material blends using high-temperature polymers and solid lubricants. Consult with our technical team for your specific environment.

Q: How does the cost compare to traditional bronze?

A: While the initial unit cost of a high-performance composite bushing may be higher, the Total Cost of Ownership (TCO) is almost always lower. This is due to the elimination of lubrication systems and labor, the drastic reduction in unplanned downtime, and a service life that can be multiple times longer than even the best bronze alloy.

Q: Can you manufacture custom or non-standard bushing designs?

A: Absolutely. Customization is one of our core strengths. Whether you need flanged bushings for axial location, unique geometries, integrated sealing features, or specific material grades for exceptional corrosion resistance, we can engineer and precision-machine a solution tailored to your exact blueprint and performance requirements.

Q: What information do you need to provide a recommendation or quote?

A: To provide the best solution, we typically need:

Application details (industry, machine type).

Operational parameters (radial/axial load, rotational speed, temperature range).

Shaft and housing dimensions (diameter, length, tolerances).

Environmental factors (presence of contaminants, moisture, chemicals).

100000+ Types of Bushings – Contact Us for Details