MYWAY DU/SF-1 Self Lubricating Bushing

Meeting the Lubrication Needs of All Your Transmission Parts

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » DU/SF-1 Self-Lubricating Bushing

DU/SF-1 Self-Lubricating Bushing

What is Self Lubricating Bushing?

Made from premium low-carbon steel, copper powder, and PTFE composites through specialized processes. Delivers excellent physical and mechanical properties. The steel layer provides high load capacity; the copper layer transfers heat and enhances bonding; the PTFE-fiber mix forms a protective transfer film. Features wear resistance, low friction, long service life, low noise, and pollution-free operation. Ideal for hard-to-lubricate areas. Widely used in industrial applications.

Self-Lubricating Bushings by Structure

Self-Lubricating Bushings by Material

Self-Lubricating Bushings by Type

Which Specification Do You Need?

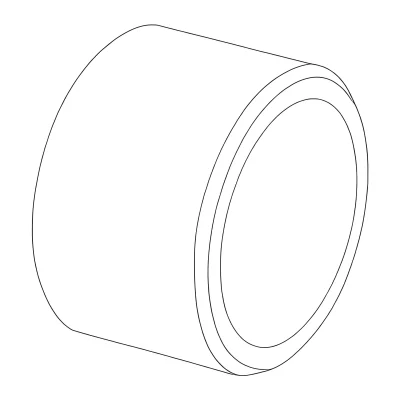

Plain Bushing

| Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. |

| 0303 | 7/4.6×3×3.8 | 1206 | 20/14×12×7 | 1820 | 26/20×18×21 | 2525 | 36/28×25×26.5 | 3525 | 49/39×35×27 |

| 0404 | 9/5.6×4×4.8 | 1208 | 20/14×12×9 | 2010 | 31/23×20×11.5 | 2615 | 38/30×26×17 | 3530 | 49/39×35×32 |

| 0504 | 10/7×5×5 | 1210 | 20/14×12×11 | 2012 | 31/23×20×13.5 | 2620 | 38/30×26×22 | 3540 | 49/39×35×42 |

| 0505 | 10/7×5×6 | 1212 | 20/14×12×13 | 2015 | 31/23×20×16.5 | 2812 | 40/32×28×14 | 3820 | 52/42×38×22 |

| 0605 | 12/8×6×6 | 1215 | 20/14×12×16 | 2020 | 31/23×20×21.5 | 2815 | 40/32×28×17 | 4012 | 54/44×40×14 |

| 0606 | 12/8×6×7 | 1410 | 22/16×14×11 | 2025 | 31/23×20×26.5 | 2820 | 40/32×28×22 | 4020 | 54/44×40×22 |

| 0607 | 12/8×6×8 | 1412 | 22/16×14×13 | 2210 | 33/25×22×11.5 | 3012 | 42/34×30×14 | 4025 | 54/44×40×27 |

| 0705 | 13/9×7×6 | 1415 | 22/16×14×16 | 2212 | 33/25×22×13.5 | 3015 | 42/34×30×17 | 4030 | 54/44×40×32 |

| 0707 | 13/9×7×8 | 1510 | 23/17×15×11 | 2215 | 33/25×22×16.5 | 3020 | 42/34×30×22 | 4040 | 54/44×40×42 |

| 0806 | 15/10×8×7 | 1512 | 23/17×15×13 | 2220 | 33/25×22×21.5 | 3025 | 42/34×30×27 | 4520 | 60/50×45×22.5 |

| 0808 | 15/10×8×9 | 1515 | 23/17×15×16 | 2415 | 35/27×24×16.5 | 3030 | 42/34×30×32 | 4525 | 60/50×45×27.5 |

| 1006 | 18/12×10×7 | 1520 | 23/17×15×21 | 2420 | 35/27×24×21.5 | 3125 | 45/35×31×27 | 4530 | 60/50×45×32.5 |

| 1007 | 18/12×10×8 | 1615 | 24/18×16×16 | 2425 | 35/27×24×26.5 | 3220 | 46/36×32×22 | 4540 | 60/50×45×42.5 |

| 1008 | 18/12×10×9 | 1620 | 24/18×16×21 | 2510 | 36/28×25×11.5 | 3225 | 46/36×32×27 | 5020 | 65/55×50×22.5 |

| 1010 | 18/12×10×11 | 1810 | 26/20×18×11 | 2512 | 36/28×25×13.5 | 3230 | 46/36×32×32 | 5030 | 65/55×50×32.5 |

| 1012 | 18/12×10×13 | 1812 | 26/20×18×13 | 2515 | 36/28×25×16.5 | 3512 | 49/39×35×14 | 5040 | 65/55×50×42.5 |

| 1015 | 18/12×10×16 | 1815 | 26/20×18×16 | 2520 | 36/28×25×21.5 | 3520 | 49/39×35×22 | …… | …… |

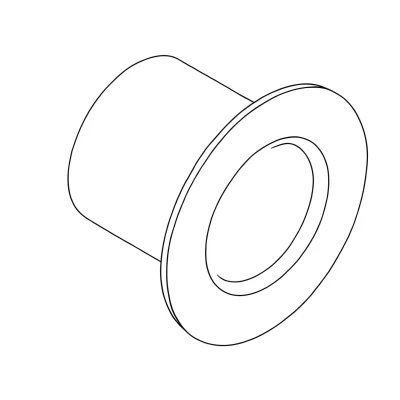

Flange Bushing

| Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. |

| 0303 | 7/4.6×3×3.8 | 1206 | 20/14×12×7 | 1820 | 26/20×18×21 | 2525 | 36/28×25×26.5 | 3525 | 49/39×35×27 |

| 0404 | 9/5.6×4×4.8 | 1208 | 20/14×12×9 | 2010 | 31/23×20×11.5 | 2615 | 38/30×26×17 | 3530 | 49/39×35×32 |

| 0504 | 10/7×5×5 | 1210 | 20/14×12×11 | 2012 | 31/23×20×13.5 | 2620 | 38/30×26×22 | 3540 | 49/39×35×42 |

| 0505 | 10/7×5×6 | 1212 | 20/14×12×13 | 2015 | 31/23×20×16.5 | 2812 | 40/32×28×14 | 3820 | 52/42×38×22 |

| 0605 | 12/8×6×6 | 1215 | 20/14×12×16 | 2020 | 31/23×20×21.5 | 2815 | 40/32×28×17 | 4012 | 54/44×40×14 |

| 0606 | 12/8×6×7 | 1410 | 22/16×14×11 | 2025 | 31/23×20×26.5 | 2820 | 40/32×28×22 | 4020 | 54/44×40×22 |

| 0607 | 12/8×6×8 | 1412 | 22/16×14×13 | 2210 | 33/25×22×11.5 | 3012 | 42/34×30×14 | 4025 | 54/44×40×27 |

| 0705 | 13/9×7×6 | 1415 | 22/16×14×16 | 2212 | 33/25×22×13.5 | 3015 | 42/34×30×17 | 4030 | 54/44×40×32 |

| 0707 | 13/9×7×8 | 1510 | 23/17×15×11 | 2215 | 33/25×22×16.5 | 3020 | 42/34×30×22 | 4040 | 54/44×40×42 |

| 0806 | 15/10×8×7 | 1512 | 23/17×15×13 | 2220 | 33/25×22×21.5 | 3025 | 42/34×30×27 | 4520 | 60/50×45×22.5 |

| 0808 | 15/10×8×9 | 1515 | 23/17×15×16 | 2415 | 35/27×24×16.5 | 3030 | 42/34×30×32 | 4525 | 60/50×45×27.5 |

| 1006 | 18/12×10×7 | 1520 | 23/17×15×21 | 2420 | 35/27×24×21.5 | 3125 | 45/35×31×27 | 4530 | 60/50×45×32.5 |

| 1007 | 18/12×10×8 | 1615 | 24/18×16×16 | 2425 | 35/27×24×26.5 | 3220 | 46/36×32×22 | 4540 | 60/50×45×42.5 |

| 1008 | 18/12×10×9 | 1620 | 24/18×16×21 | 2510 | 36/28×25×11.5 | 3225 | 46/36×32×27 | 5020 | 65/55×50×22.5 |

| 1010 | 18/12×10×11 | 1810 | 26/20×18×11 | 2512 | 36/28×25×13.5 | 3230 | 46/36×32×32 | 5030 | 65/55×50×32.5 |

| 1012 | 18/12×10×13 | 1812 | 26/20×18×13 | 2515 | 36/28×25×16.5 | 3512 | 49/39×35×14 | 5040 | 65/55×50×42.5 |

| 1015 | 18/12×10×16 | 1815 | 26/20×18×16 | 2520 | 36/28×25×21.5 | 3520 | 49/39×35×22 | …… | …… |

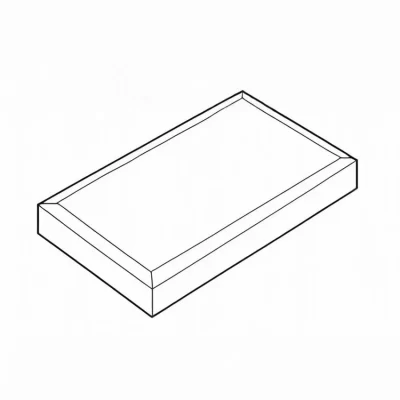

Slide Block

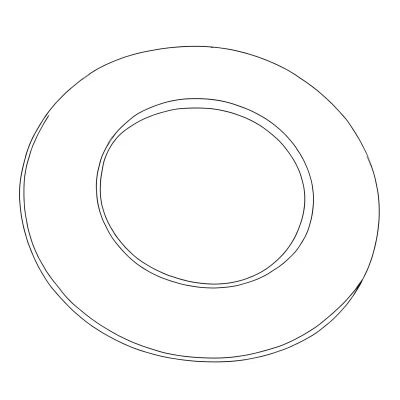

Thrust Washer

| Type | Spec | Type | Spec |

| DP10 | 20×10×1.5 | DP26 | 44×26×1.5 |

| DP12 | 24×12×1.5 | DP28 | 48×28×1.5 |

| DP14 | 26×14×1.5 | DP32 | 54×32×1.5 |

| DP16 | 30×16×1.5 | DP36 | 62×36×1.5 |

| DP18 | 32×18×1.5 | DP42 | 66×42×1.5 |

| DP20 | 36×20×1.5 | DP48 | 74×48×2 |

| DP22 | 38×22×1.5 | DP52 | 78×52×2 |

| DP24 | 42×24×1.5 | DP62 | 90×62×2 |

| Designation | Length(+5/0) | Width(+2/0) | Thickness(0/-0.05) | ||||

| BC100SF | 500 | 125 | 1.0 | ||||

| BC150SF | 500 | 125 | 1.5 | ||||

| BC200SF | 500 | 125 | 2.0 | ||||

| BC250SF | 500 | 125 | 2.5 | ||||

| BC300SF | 500 | 125 | 3.0 |

MYWAY products can be tailored to your specific requirements.

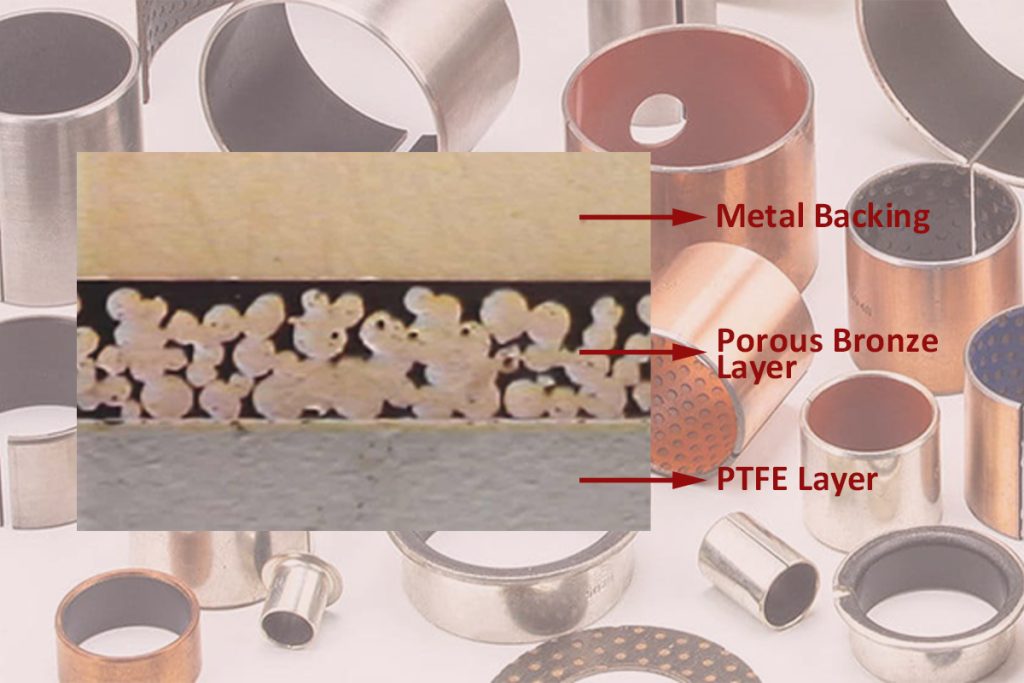

Structure of Self Lubricating Bushing

The outermost layer of Myway self-lubricating bearing is metal, and there are many materials to choose from, such as carbon steel, bronze, stainless steel 304/316, aluminum, etc., which provide outstanding wear resistance and solid support, effectively extending the service life of bushing.

The bronze powder is sintered into dense structure in high-pressure environment of 800℃, which can firmly connect the metal layer and the PTFE lubricating layer to prevent delamination. With thickness of 0.1-0.3mm and porosity of 25%-40%, it can store solid lubricants and dissipate heat quickly.

The lubricating layer is composed of a mixture of high-quality PTFE and lead with thickness of 0.01-0.03 mm, greatly reduce the noise during mechanical operation. Its low friction coefficient (0.03-0.2μ) enables it to achieve long-term operation without external lubrication.

Features of Self Lubricating Bushing

- Self-lubricity without oil holes and external lubrication

- Maintenance-free feature reduces machinery operating costs

- Having more cost-effective thanks to its long service life

- High-quality PTFE liner with low friction surface and self-lubricating properties

- Embedded solid lubricant ensures smooth operation with minimal friction

- High load capacity, even in harsh environments with high temperature and dust

- Corrosion-resistant metal materials, suitable for use in acidic or humid environments

- Various materials to choose from: steel, copper, stainless steel 304/316, etc.

- Simple installation method, easily interchangeable with traditional bushings.

- Low friction coefficient reduces energy consumption and improves lubrication efficiency

Direct Replacements For

| Brand | Series/Models |

|---|---|

| GGB | DU, DP4, DP10, DP31 |

| SKF | PCM, PCZ PTFE Composite Bushings |

| DAIDYNE | DDK05, DDL05, DDK35, DDK55, DDK02, DDL02, DDK06 |

| PTI | PAP P10, PAW P10 |

| ISB | SF-1 |

| CSB | CSB50 |

| GLT | TFZ, TEF |

| DE | SBT |

| COB | PBM |

| Daemar | TH |

| Sankyo Oiless | LBM, LBMF |

Applications of Self Lubricating Bushing

Our Factory

At MYWAY, our DU/SF-1 self-lubricating bushings are manufactured on highly specialized production lines. Key equipment includes a fully automated atmosphere-protected sintering system that achieves a solid bond between spherical bronze powder and steel backing; precision PTFE rolling equipment that ensures perfect coverage of a low-friction, wear-resistant surface layer; CNC sizing machines that maintain micron-level tolerances; and a fully automated optical inspection system that provides quality assurance for every product.

MYWAY PTFE-Based Self-Lubricating Bushings: The Ultimate Maintenance-Free Solution for Industrial Applications

Introduction: Revolutionizing Industrial Motion with Self-Lubricating Technology

In today’s demanding industrial environments, maintenance downtime and lubrication-related failures can significantly impact productivity. MYWAY self-lubricating bushings with advanced PTFE technology provide the perfect solution, offering exceptional performance across extreme temperatures, corrosive conditions, and inaccessible locations. As leading innovators in maintenance-free bearings and self-lubricating sliding bushings, we engineer solutions that extend equipment life while reducing operational costs.

Understanding Self-Lubricating Bushing Technology

What Are Self-Lubricating Bushings?

Self-lubricating bushings (also known as metal-polymer bearings, maintenance-free bearings, greaseless bearings, or plain bearings) incorporate solid lubricants directly into their structure, eliminating the need for external lubrication systems. These components continuously transfer lubricant to the contact surface during operation, creating a protective film that reduces friction and wear.

How MYWAY Self-Lubricating Bushings Work

Our PTFE-based bearings employ sophisticated mechanisms to ensure consistent lubrication:

Solid Lubricant Integration: PTFE (Polytetrafluoroethylene) and other solid lubricants are embedded within the bearing matrix, providing continuous lubrication through material transfer

Reservoir Technology: Specially engineered pores and fiber networks act as lubricant reservoirs, steadily releasing lubricant throughout the bearing’s operational life

Transfer Film Formation: During operation, these materials form a protective PTFE-rich layer on mating surfaces, preventing metal-to-metal contact and reducing friction coefficients

MYWAY Product Series: Engineered for Specific Application Needs

MYWAY DU/SF-1 Series: Triple-Layer Composite Bearings

The DU/SF-1 series represents our flagship metal-polymer plain bearings with innovative three-layer construction:

Steel Backing Layer: Provides structural integrity and mounting stability

Bronze Powder Interlayer: Enhances thermal conductivity and bonding strength

PTFE-Based Polymer Layer: Delivers superior wear resistance and self-lubricating properties

Applications: Automotive suspensions, industrial robotics, construction equipment, and precision machinery where space constraints and reliability are critical.

MYWAY DU/SF-1B Series: Bronze-Based Heavy-Duty Bushings

Engineered for extreme conditions where traditional bearings fail:

Base Material: High-strength tin bronze substrate

Intermediate Layer: Sintered spherical bronze powder for enhanced thermal management

Surface Layer: PTFE with high-temperature fillers optimized for dry-running conditions

Key Advantages:

Exceptional thermal conductivity dissipates operational heat

Superior load capacity for heavy-duty applications

Excellent performance in high-temperature environments

Ideal for steel industry equipment, high-temperature furnaces, and heavy machinery

MYWAY DU/SF-1S Series: Stainless Steel Corrosion-Resistant Bushings

Specifically developed for corrosive and sanitary environments:

Stainless Steel Base: Maximum corrosion resistance

Special Alloy Powder Layer: Engineered for chemical compatibility

Lead-Free PTFE Surface: Safe for food, pharmaceutical, and chemical processing

Industry Applications:

Food and beverage processing equipment

Chemical pumps and valves

Pharmaceutical manufacturing machinery

Marine and offshore applications

Water treatment systems

Technical Advantages of MYWAY Self-Lubricating Solutions

Performance Benefits:

Zero Maintenance Operation: Eliminate lubrication schedules and associated costs

Extended Service Life: Reduce replacement frequency and downtime

Extreme Environment Capability: Perform reliably from -200°C to +280°C

Corrosion Resistance: Withstand harsh chemicals, seawater, and acidic/alkaline conditions

Energy Efficiency: Lower friction coefficients reduce power consumption

Environmental Safety: Lead-free formulations and no lubricant leakage

Material Science Excellence

Our self-lubricating composite bushings benefit from advanced material engineering:

PTFE and Fiber Mixtures: Optimized for transfer film formation and shaft protection

Spherical Metal Powders: Enhance load distribution and thermal management

Multiple Substrate Options: Bronze, stainless steel, or carbon steel tailored to application requirements

Industry Applications and Success Stories

MYWAY self-lubricating bearings serve critical functions across diverse sectors:

Automotive Engineering: Steering systems, suspension components, and engine applications

Industrial Machinery: Hydraulic systems, pumps, compressors, and conveyor equipment

Heavy Equipment: Construction machinery, mining equipment, and agricultural implements

Renewable Energy: Wind turbine components, solar tracking systems

Marine Technology: Steering mechanisms, propulsion systems, and deck equipment

Aerospace: Control systems, landing gear, and access panels

Selection Guide: Choosing the Right MYWAY Bushing

Critical Selection Factors:

Load Conditions: Static and dynamic loading requirements

Operating Environment: Temperature range, chemical exposure, contamination risk

Movement Type: Rotary, oscillating, or linear motion patterns

Space Constraints: Available installation dimensions and wall thickness requirements

Regulatory Compliance: Food-grade, military, or aerospace certifications

Product Matching Guide:

MYWAY DU/SF-1 Series: General industrial applications, space-constrained designs

MYWAY DU/SF-1B Series: High-temperature, heavy-load industrial applications

MYWAY DX/SF-1S Series: Corrosive environments and sanitary applications

Installation and Maintenance Best Practices

Installation Guidelines:

Ensure proper housing dimensions and surface finish

Maintain correct press-fit tolerances

Verify alignment during installation

Use appropriate installation tools to prevent damage

Operational Monitoring:

Regular visual inspection for abnormal wear patterns

Monitor operating temperatures

Check for unusual noise or vibration

Maintain records of service life and performance

Why Choose MYWAY Self-Lubricating Solutions?

Technical Superiority:

Advanced PTFE formulations for specific application requirements

Comprehensive product range covering most industrial needs

Rigorous quality control and performance testing

Technical support and engineering consultation services

Customer Benefits:

Reduced total cost of ownership through extended service life

Custom engineering solutions for unique applications

Global supply chain and reliable delivery

Expert application engineering support

REQUEST YOUR FREE ENGINEERING CONSULTATION

Ready to eliminate lubrication-related downtime and enhance your equipment’s reliability? Contact MYWAY’s engineering team today for:

Application-specific product recommendations

Custom design and manufacturing services

Performance testing and validation

Competitive pricing and delivery information

Explore our complete product catalog and technical resources.

MYWAY Self-Lubricating Solutions: Engineered for Performance, Built for Reliability

MYWAY Self-Lubricating Bushing FAQs

1. How Much Longer is the Life of Self Lubricating Bushings than Traditional Bushings?

According to test data, the life of a self lubricating bushing is usually 2-3 times that of a traditional lubricated bushing, depending on the application. For example, in the suspension system of a heavy-duty truck, a traditional bushing may need to be maintained every 10,000 km, while a self lubricating bushing can be extended to more than 30,000 km.

2. Do Self Lubricating Bushings need Regular Maintenance?

There is no need to add lubricant regularly, and its self-lubricating characteristics can maintain the whole service life. However, it is recommended to observe the wear of the bushing during each equipment inspection to ensure that there is no abnormality.

3. How High can the Self Lubricating Bushings Withstand?

Different materials have different temperature resistance. For example, PTFE base sleeves can withstand temperatures up to 260 C, while some composites are suitable for the range of-40 C to 150 C. You can select the specific model according to your application.

4. Is There any Special Tool Required to Install Self Lubricating Bushings?

The installation process is similar to that of a traditional bushing. It is usually pressed or hot fitted without special tools. However, it is necessary to ensure that the mating tolerance is in line with the manufacturer’s recommendation to avoid installation damage.

5. what is a du bushing

A DU bushing, also referred to as a DU bearing, is a specific category of sliding bearing recognized for its outstanding self-lubricating characteristics. It falls under the classification of multi-layer composite materials and is engineered to deliver reliable, maintenance-free performance in demanding applications.

(1) Structural Composition of DU Bushings

The construction of a standard DU bushing features a robust three-layer design:

A steel backing that offers fundamental structural integrity and support.

An intermediate porous bronze layer, which serves as a solid matrix for retaining and uniformly distributing the lubricant.

A top PTFE-based lining that provides a low-friction surface and is responsible for the component’s primary self-lubricating properties.

(2) Key Characteristics and Advantages

The defining feature of DU bushings is their self-lubricating capability. The PTFE lining functions as a solid lubricant, effectively minimizing friction and wear between the bushing and the mating shaft. This inherent property removes the dependency on external lubrication systems, making these bushings particularly suitable for applications where routine maintenance or lubrication is impractical.

DU bushings provide several significant operational benefits. They exhibit a consistently low coefficient of friction, which contributes to reduced energy consumption and enhanced operational efficiency. Furthermore, they demonstrate exceptional wear resistance, enabling them to endure high loads and perform reliably under severe operating conditions.

5. What is the Cost Effectiveness of Self Lubricating Bushings?

The initial cost may be 20-30% higher than the traditional bushings, but the long-term maintenance cost can be reduced by more than 50%. In the working device of an excavator, the use of self-lubricating bushings can save about 30% of the maintenance costs per year.

6. How to Choose the Right Bushing Model for My Application?

You should take the load, speed, temperature, environment and other factors into consideration . Myway can provide selection guidelines, or customizing according to your specific parameters.

7. How does the Self Lubricating Bushing Perform in a Dusty Environment?

The polymer coating of self lubricating bushing has good wear resistance and dustproof performance, making it suitable for dusty environments like construction site loaders. Tests show that in dusty environments, the self-lubricating bushing has a wear rate 40% lower than traditional bushings.

8. What are the Advantages of Self Lubricating Bushings over Bronze Bushings?

Self-lubricating bushings require no lubrication, are lighter in weight, have lower friction coefficient (about 0.05-0.1 vs. 0.15-0.2 for brass), and are more resistant to corrosion, especially in wet or corrosive environments.