Home » DU/SF-1 Self-Lubricating Bushing » DU/SF-1 Steel-Backed Self-Lubricating Bushing for Reciprocating Motion

DU/SF-1 Steel-Backed Self-Lubricating Bushing for Reciprocating Motion

This product is engineered with a novel formula specifically designed for the demanding conditions of reciprocating motion. Its performance is comparable to international standard DD2, delivering exceptional self-lubrication under oil-starved conditions, outstanding wear resistance, and the ability to maintain a consistent oil film. This bushing effectively protects the mating shaft surface from wear and damage.

Widely used in automotive shock absorbers, motorcycle dampers, hydraulic cylinders, hydraulic motors, pneumatic components, and other applications requiring reliable sliding performance under high-stress reciprocating cycles.

Technical Parameters

Max. Load Capacity: 140 N/mm²

Coefficient of Friction, μ: 0.04–0.20

Operating Temperature Range: -195 °C to +280 °C

Max. Allowable PV Value (Dry): 3.6 N/mm²·m/s

Max. Sliding Speed: 2.5 m/s

Max. Allowable PV Value (Lubricated): 50 N/mm²·m/s

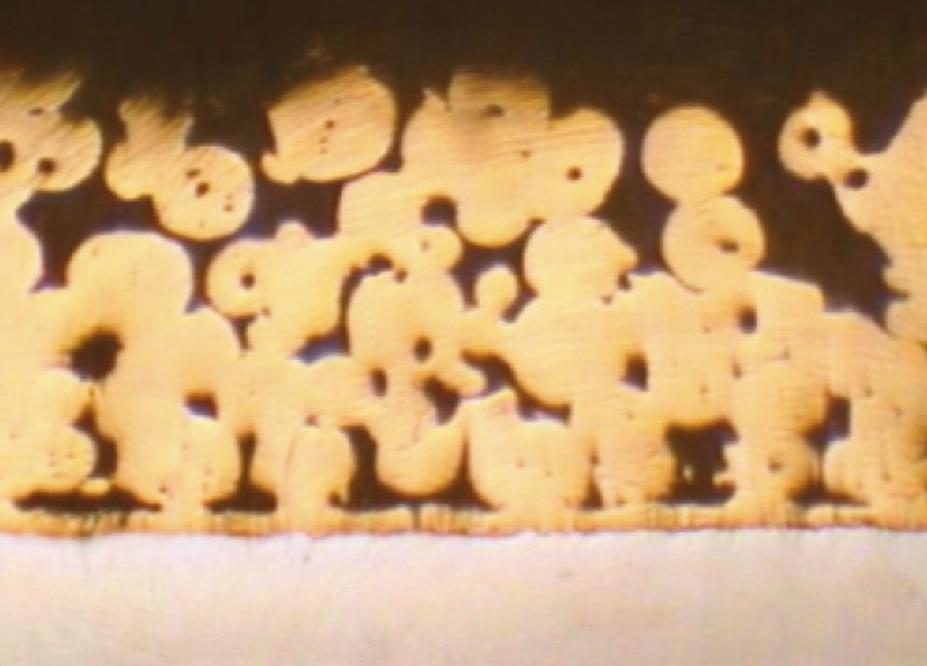

Metallurgical Analysis

- PTFE and Copper Composite Layer

- Spherical Bronze Powder Matrix

- Steel Backing for Structural Support

- Electroplated Surface: Tin-Plated or Copper-Plated Layer

FAQs

What are the product features of Steel-Backed Self-Lubricating Bushing for Reciprocating Motion?

Excellent self-lubricating capability under oil-starved conditions, superior wear resistance, and ability to maintain a clear lubricating film.

Effectively protects the mating shaft surface from wear and extends its service life.

Highly suitable for reciprocating motion applications, even with frequent directional changes and high lateral loads.

Operates reliably with minimal or no lubrication, ideal for hard-to-access or maintenance-free applications where regular servicing is impractical.