MYWAY Bushings for Every Part of Your Excavators

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Bushings by Excavator Brands

Regardless of your excavator’s brand or model, we supply precision-engineered OEM-equivalent bushings that reduce costs without compromising performance.

We support all major brands, including:

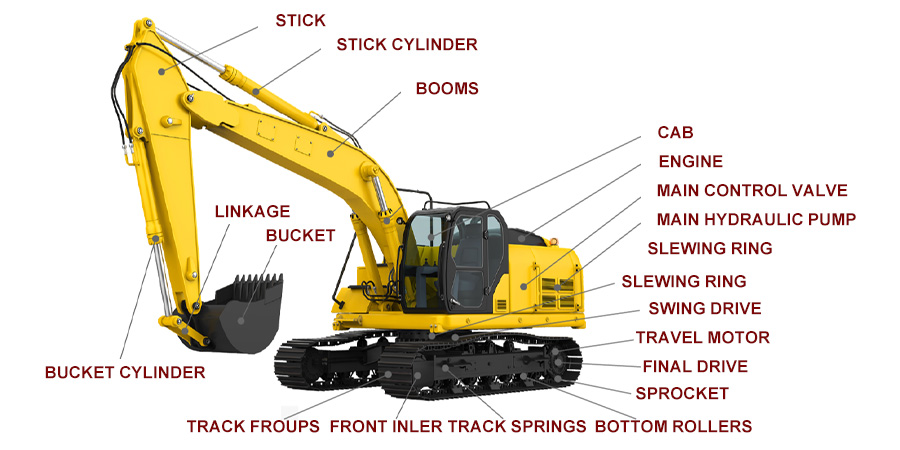

MYWAY Bushings by Excavator Components

Home » Excavator

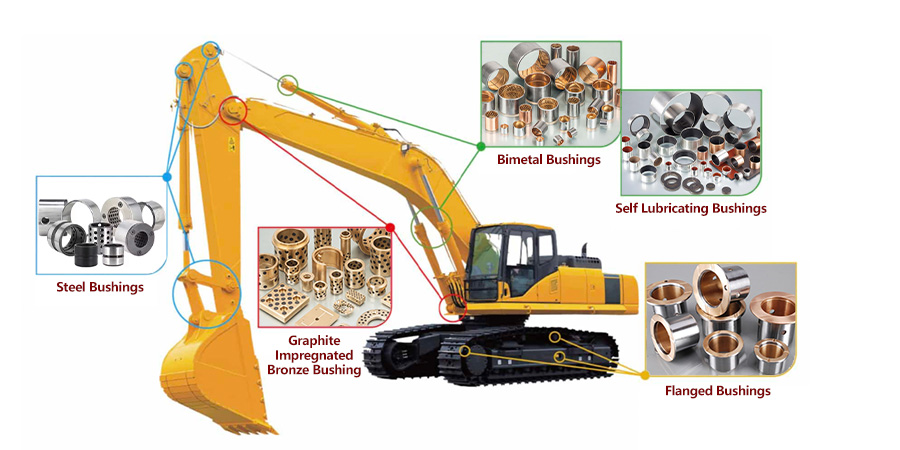

MYWAY Bushings: Enhance Excavator Performance & Durability

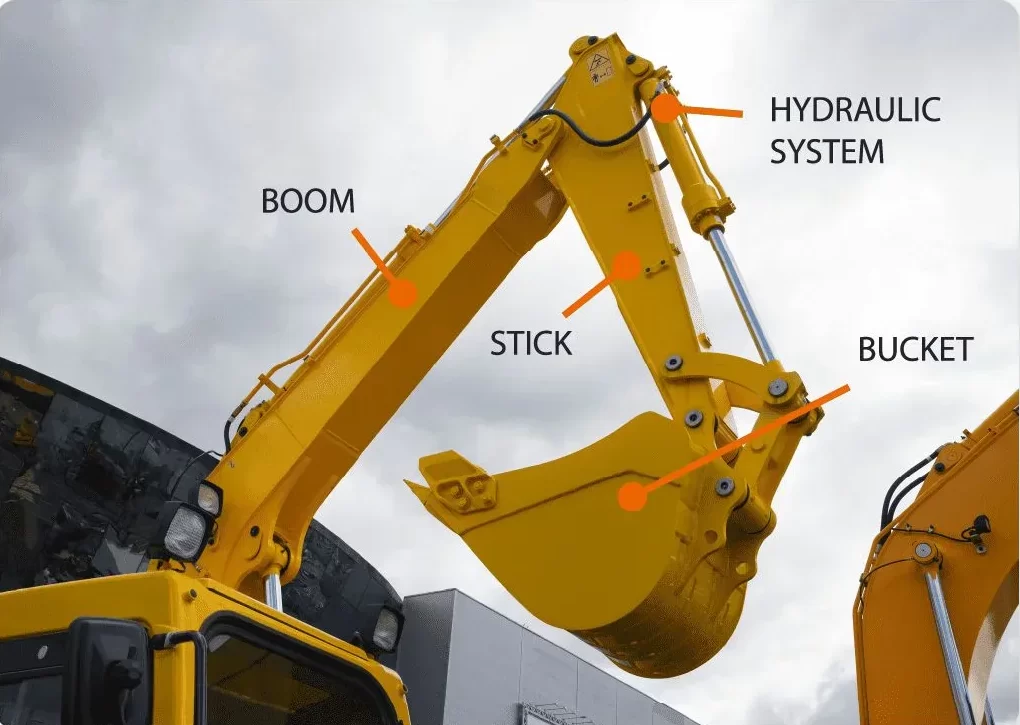

Bushings are critical components in excavators, playing a vital role in enhancing operational efficiency and extending the machine’s service life. They are strategically installed in high-stress areas such as the boom, arm, stick, and bucket to minimize friction and wear between moving metal parts. Designed to withstand heavy loads and harsh working conditions, they also allow for straightforward replacement when worn or damaged.

1. Boom ➊

The boom serves as the primary support structure of the excavator’s working mechanism. It performs lifting and lowering movements through the extension and retraction of the boom cylinder, adjusting the height and position of the bucket to suit various digging depths and operational needs.

Bushing Type: Bronze bushings, self-lubricating bushings

2. Arm & Stick

The arm (or dipper) is connected to the boom and enables extension and contraction via the bucket cylinder. Its length and angle determine the working range and digging angle of the bucket, allowing the machine to perform digging and loading tasks efficiently.

Bushing Type: Steel bushings

3. Bucket

The bucket interacts directly with materials and is used for digging, loading, and transporting. It comes in various designs—such as front shovel, backhoe, clamshell, and grab buckets—to match specific operational requirements.

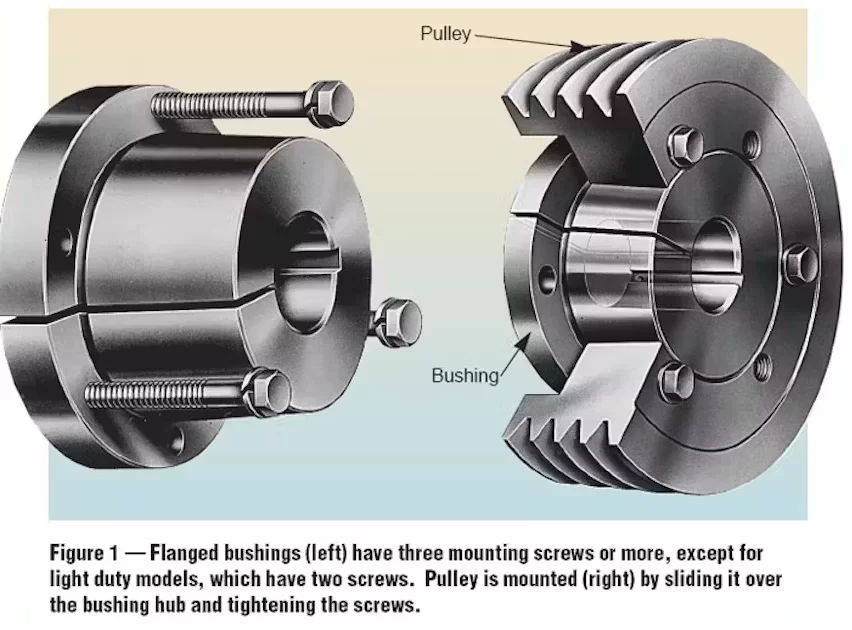

Bushing Type: Flanged bushings, excavator bucket bushings

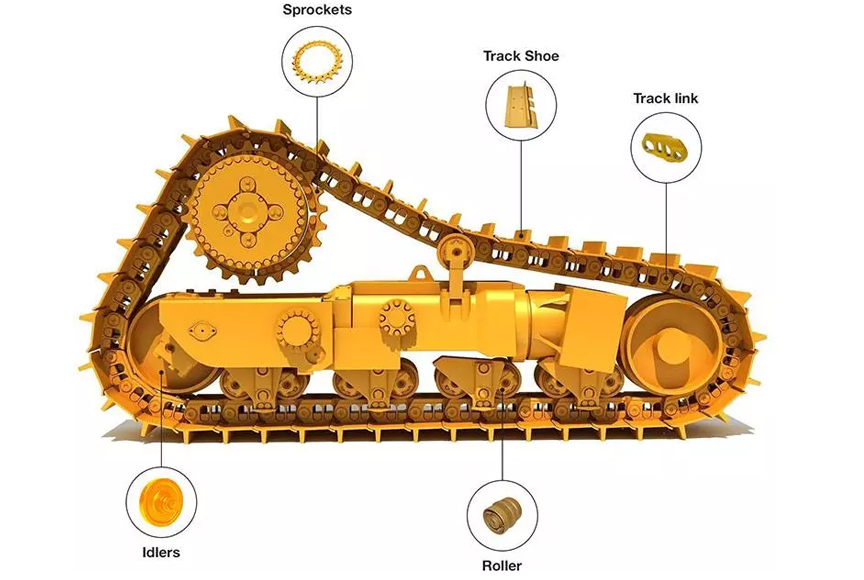

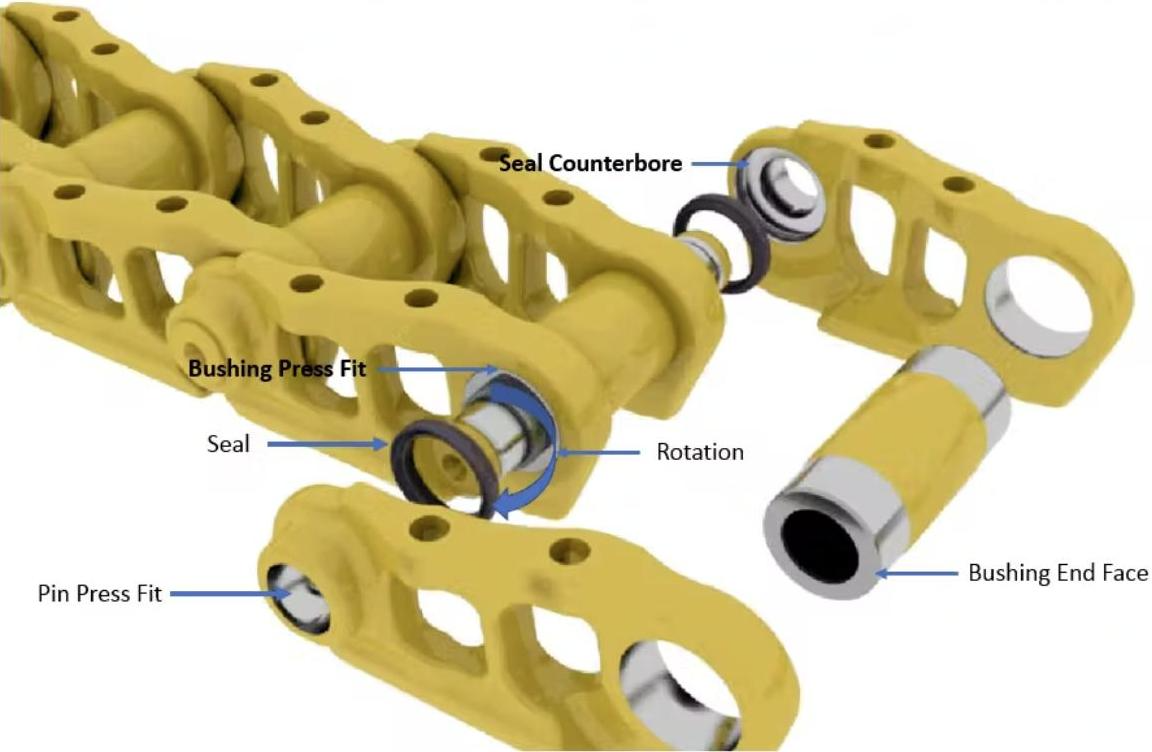

4. Crawler Track System ➋

The crawler system consists of track plates, track pins, and track links, forming the excavator’s undercarriage. It provides stability, distributes ground pressure evenly, and ensures reliable traction across challenging terrains.

Bushing Type: Steel bushings, Bimetal Bushing: CuPb10Sn10,

CuPb24Sn4 , Bronze Bushings, Powder Metallurgy Bushing

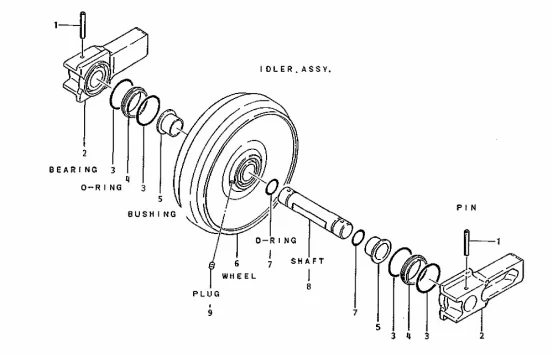

5. Guide Wheel (Idler) ➌

Located at the front of the undercarriage, the guide wheel maintains track alignment, directs travel motion, and helps adjust track tension to prevent over-tightening or excessive slack.

Bushing Type: Steel bushings

6. Support Roller ➍

The support rollers bear the weight of the excavator and evenly distribute load across the track, reducing wear and prolonging track life.

Bushing Type: Steel bushings, bimetal materials

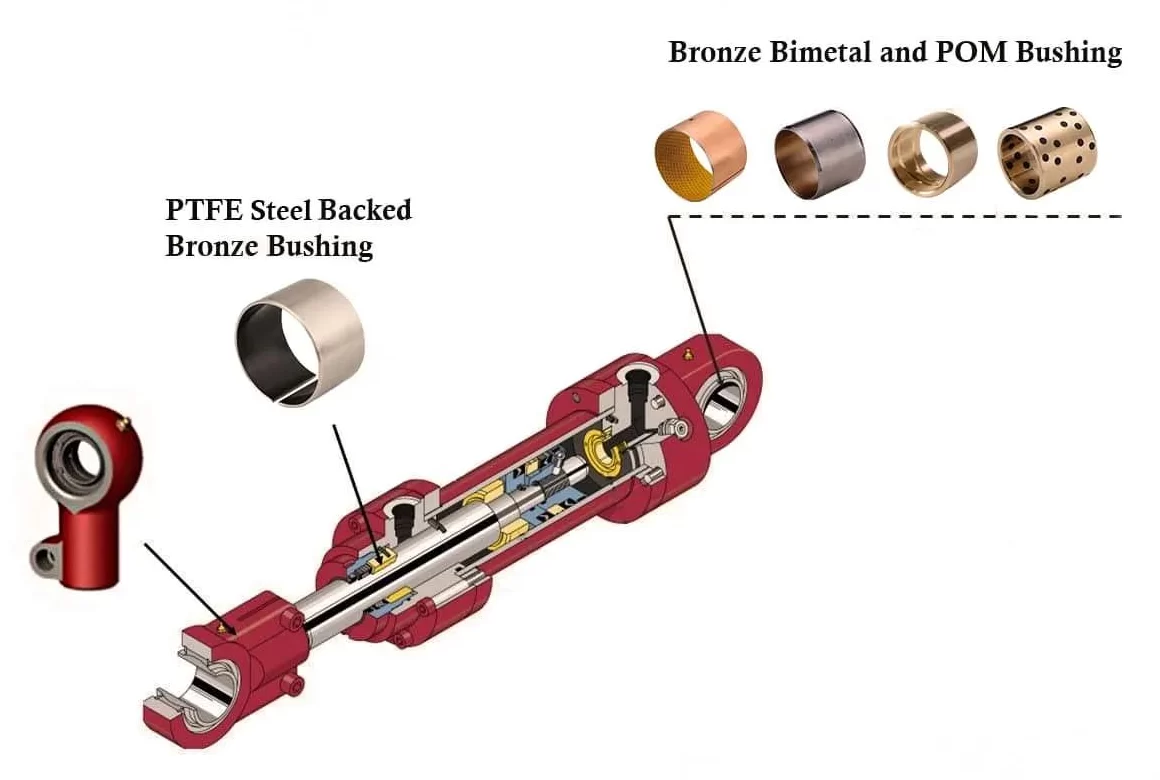

7. Hydraulic Cylinder ➎

Hydraulic cylinders act as actuators within the hydraulic system, converting fluid pressure into mechanical energy to drive linear and pivoting motions of the boom, arm, and bucket.

Bushing Type: Bronze bushings, self-lubricating bushings

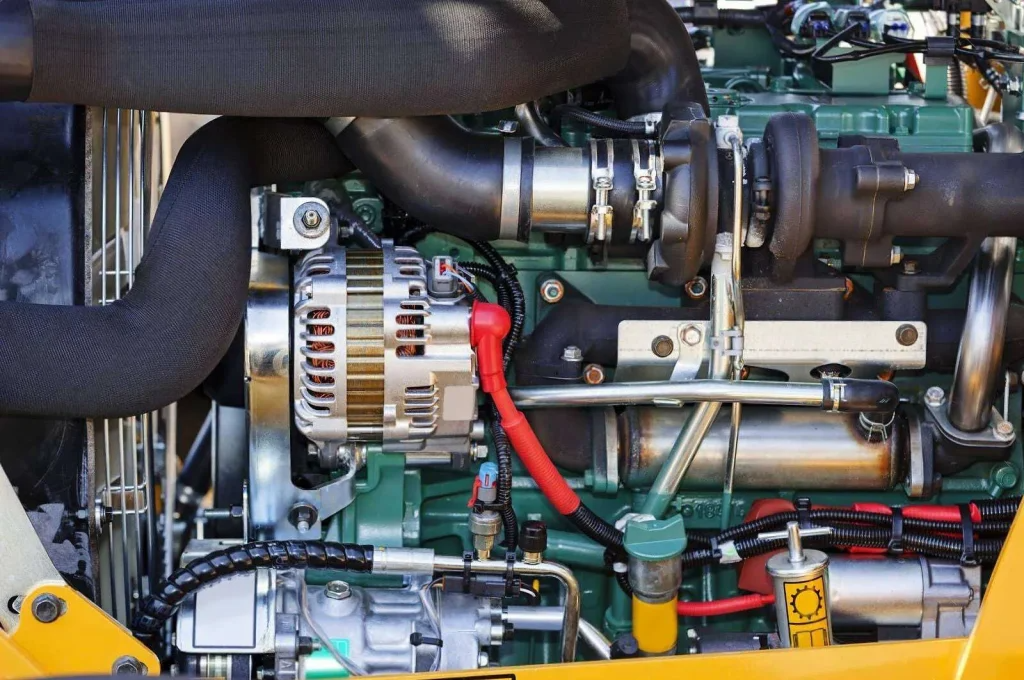

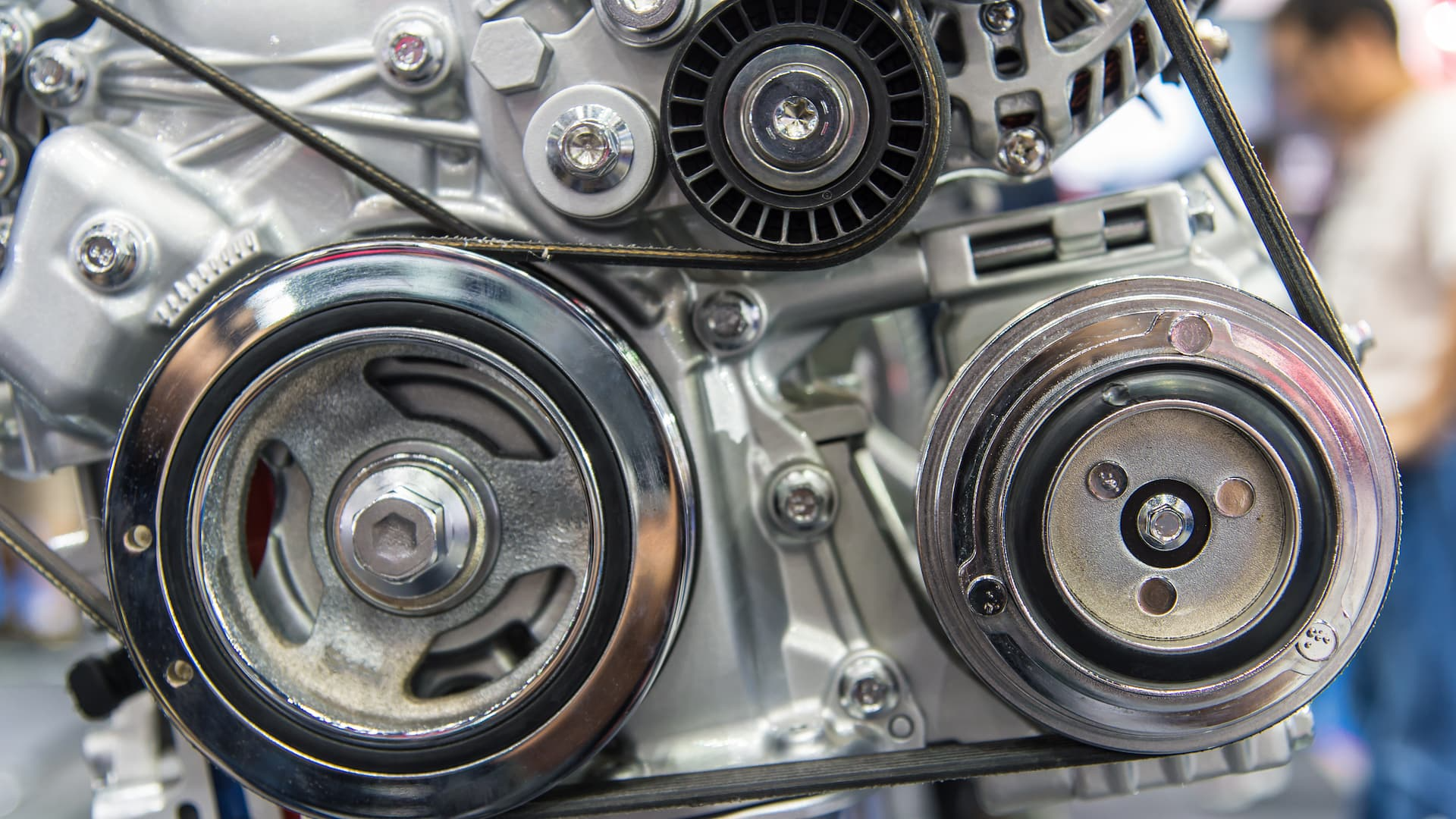

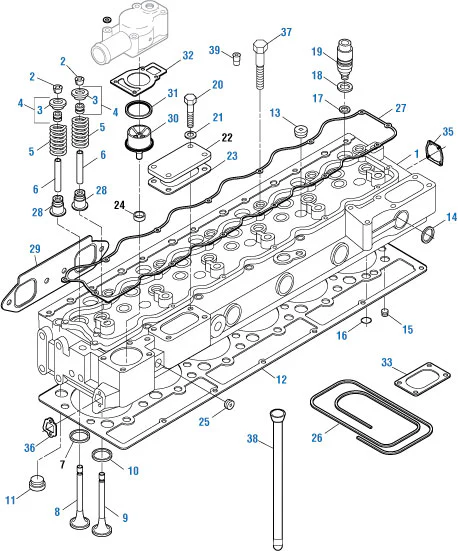

8. Engine Systems ➏

The engine is the heart of the excavator, and its components operate under extreme pressures and temperatures. Bushings here are critical for reducing friction, minimizing vibration, and ensuring longevity of the core powertrain.

Cylinder Liners (Wet Sleeves): While not a traditional bushing, cylinder liners are a form of sleeve bearing that guide the piston and contain combustion gases. They are fundamental to engine performance and rebuilds.

Bushing Type: Bronze bushings, precision-engineered steel-backed bushings.

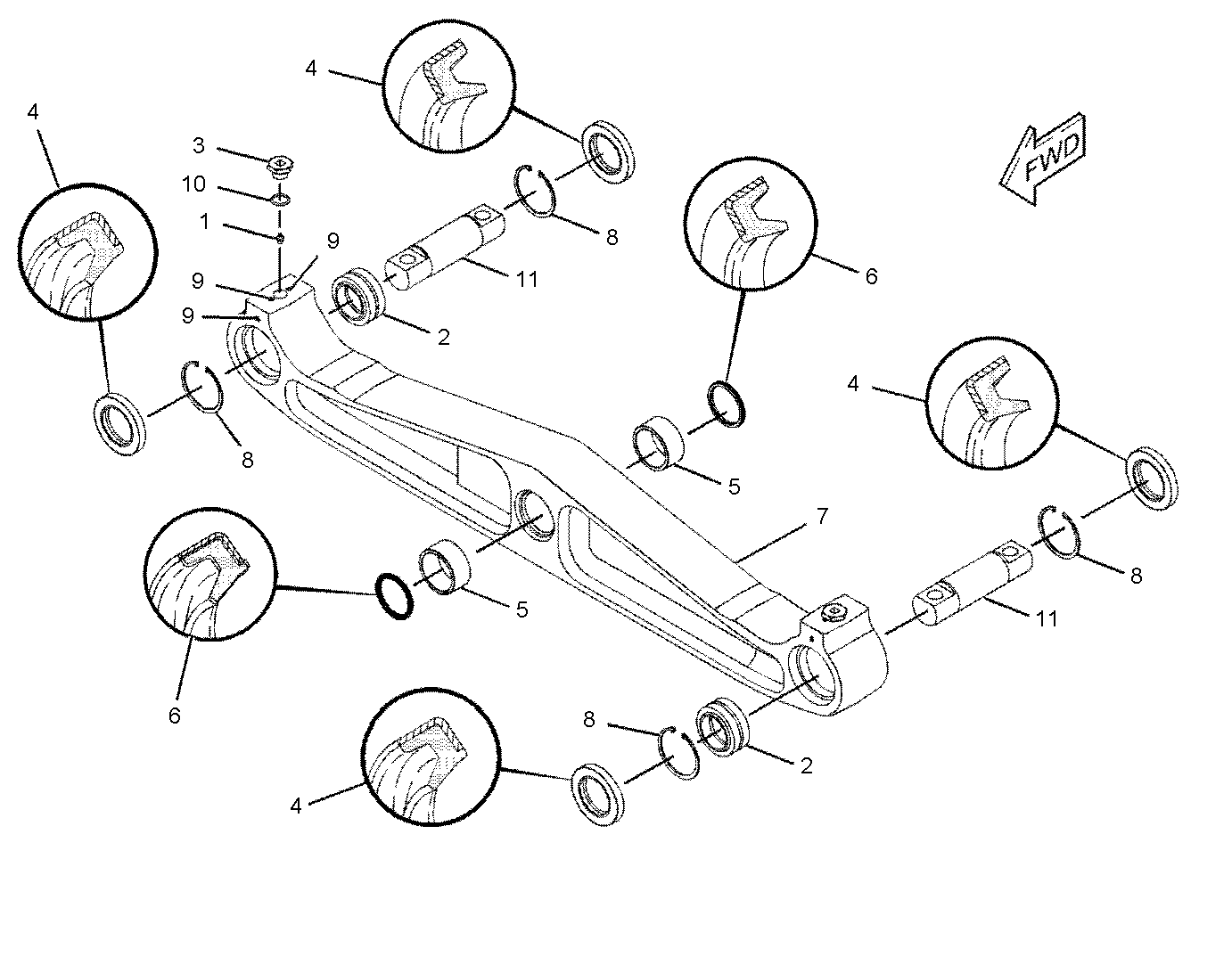

9. Equalizer Bar & Suspension Linkage ➐

The equalizer bar (or swing circle) connects the upper structure to the undercarriage, allowing the cab to rotate. Its linkage system relies on robust bushings to absorb shock loads and ensure smooth, controlled swinging.

Bushing Type: Heavy-duty steel bushings, flanged bushings, self-lubricating bushings

MYWAY provides high-performance, precision-engineered bushings for all these applications—from the undercarriage and implements to the engine, powertrain, and hydraulic systems—ensuring reliability, reduced maintenance, and extended excavator life even in the most demanding conditions.

Excavator Bushings: The Ultimate Guide to Types, Functions, and Maintenance

Excavator bushings, often referred to as excavator bearings, are critical components specifically designed for the pivot points in an excavator’s arm (boom and dipper) and bucket. While the entire machine utilizes various bushings, the term “excavator bushing” is reserved for these high-stress, load-bearing connections. They are fundamental to the machine’s functionality, ensuring smooth, precise, and sturdy movement under extreme loads. Understanding their role, types, and maintenance is key to maximizing excavator performance and minimizing costly downtime.

What is an Excavator Bushing?

An excavator bushing is a cylindrical or tapered metal sleeve that acts as a bearing surface, supporting and guiding a shaft or pin. It connects different parts of the machinery, such as the boom, arm, and bucket, allowing for articulation while withstanding immense pressure and shock loads. These components are essential for the excavator’s precision and operational stability.

Key Locations for Bushings:

Excavator Boom Bushing: Located where the boom connects to the excavator’s body.

Excavator Arm Bushing: Found at the pivot points connecting the arm to the boom and the bucket.

Bucket Pin Bushings: Used where the bucket attaches to the arm.

Linkages: Present in the connecting pieces between the boom, arm, and bucket.

Undercarriage: Used in rollers and idlers of tracked excavators.

Hydraulic Cylinders: Installed at the eye ends and mounting points.

What Are Excavator Bushings Made Of?

Due to the severe loads and harsh environments, excavator bushings are manufactured from robust, hardened materials. The most common include:

Hardened Steel Alloys: Such as 45Steel, 40Cr, and 20CrMnTi, known for their high strength and impact resistance. These often undergo heat treatments like high-frequency quenching, carburizing, or nitriding to enhance surface hardness and durability.

Bronze (Tin Bronze): Alloys like C90300 or QSn6.5-0.1 are prized for their excellent wear resistance, corrosion resistance, and self-lubricating properties. The lead phase in materials like C90300 creates a natural lubricating film, reducing friction and preventing seizure.

Composite Materials: These include steel-backed sintered bronze with PTFE or POM coatings, offering a combination of high strength and self-lubrication.

Stainless Steel: Used in highly corrosive environments, such as wetlands or chemical sites.

Types of Excavator Bushings

Selecting the right bushing type is crucial and depends on the excavator’s size and application.

Solid Bushings: Made from a single piece of metal, offering high structural strength for heavy-load and high-impact conditions.

Split Bushings: Also known as split bushings, these consist of two halves for easy replacement and quick installation in high-maintenance areas.

Self-Lubricating Bushings (Oilless Bearings): These bearings are embedded with solid lubricants like graphite, PTFE, or copper powder. They are ideal for dusty, dirty environments or where regular lubrication is difficult, reducing maintenance frequency.

Flanged Bushings: Feature a flange at one end to provide a thrust surface, preventing axial movement.

Inlaid Bushings: Have carbide or high-hardness ceramic inserts embedded in the friction surface for extreme wear resistance in mining and rock operations.

How Do Excavator Bushings Work?

Bushings act as pivot points between moving components. They create a wear-resistant bearing surface for pins to rotate or oscillate against. In self-lubricating designs, the embedded solid lubricant provides a continuous thin film between the pin and bushing, reducing friction, wear, and heat generation. As the material wears, this lubrication layer is replenished, ensuring long-lasting, maintenance-free operation. By absorbing shock and vibration, bushings protect more expensive components like the boom and arm assemblies, acting as sacrificial wear parts that are more cost-effective to replace.

Benefits of Using High-Quality Excavator Bushings

Investing in premium bushings delivers significant returns:

Improved Machine Performance: Reduces friction for smoother, more efficient operation.

Extended Service Life: Withstands heavy loads and harsh conditions, lasting thousands of hours.

Reduced Downtime: Minimizes the frequency of repairs and replacements.

Enhanced Safety: Prevents accidents caused by worn-out or failed components.

Lower Maintenance Costs: High-quality, self-lubricating bushings require less frequent lubrication and repair.

How to Maintain Your Excavator Bushings

Proper maintenance is essential for longevity.

Regular Inspection: Frequently check for signs of wear, such as cracks, deformation, rust, or excessive play. Replace if the pin-to-bushing clearance exceeds 0.5mm.

Proper Lubrication: For non-oilless bushings, apply the correct grease regularly to reduce friction and wear. Ensure grease points are clean before application.

Keep Areas Clean: Prevent dirt and debris from accumulating around bushings to avoid accelerated wear.

Avoid Excessive Loads: Operate within the excavator’s rated capacity to prevent undue stress on the bushings.

Replace in Pairs: Always replace both the bushing and its corresponding pin simultaneously to ensure a proper fit and avoid premature wear.

How to Remove and Replace Excavator Bushings

Bushing replacement is an in-depth task that requires experience and heavy equipment. It is recommended for experienced professionals.

Recognize Wear Signs: Look for excessive joint play, unusual noises, or visual deterioration.

Disassembly: Carefully dismantle the affected component, taking care not to damage the pins or housing seats.

Cleaning: Thoroughly clean the bushing housing before installing the new component.

Installation: Use specialized tools like presses, or techniques like freezing the new pin (to shrink it) and heating the bushing (to expand it) for a precise fit.

Post-Replacement Lubrication: Apply adequate lubricant to ensure optimal initial operation.

Selecting the Right Bushings for Your Excavator & Working Conditions

Choosing the correct bushing involves several factors:

Machine Tonnage: Bushing size is directly related to excavator size.

Mini Excavators: Require bushings for precise, agile movements.

Mid-Sized Excavators: Need bushings that balance strength and flexibility.

Large Excavators: Demand exceptionally robust bushings for extreme forces.

Material: Consider strength, toughness, and environmental conditions (e.g., corrosion resistance).

Type: Select from solid, split, or self-lubricating types based on load and maintenance needs.

Working Conditions:

Mining/Rock Operations: Use high-strength alloy steel bushings (e.g., 42CrMo) with deep hardening.

Urban Construction: Split bronze bushings offer a good balance of performance and easy maintenance.

Wetlands/Water: Opt for stainless steel pins and corrosion-resistant bushings like POM nylon or bronze with seals.

Cold Environments: Select low-temperature toughness alloy steel and self-lubricating bushings.

Desert/High-Temperature: Use heat-resistant materials like nickel-chromium steel and self-lubricating copper alloy bushings.

Conclusion

Excavator bushings may be small components, but they bear immense responsibility for the machine’s efficiency, safety, and longevity. From material selection and precise matching with pins to proper maintenance and condition-specific selection, every detail counts. By investing in high-quality bushings, performing regular inspections, and adhering to proper replacement protocols, you can ensure your excavator operates smoothly, reduce unplanned downtime, and protect your valuable equipment investment.

Upgrade your excavator’s performance today. Don’t let worn-out bushings slow you down—invest in durable, high-performance solutions for maximum uptime and productivity.