MYWAY Bushings for Every Part of Your Excavators

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

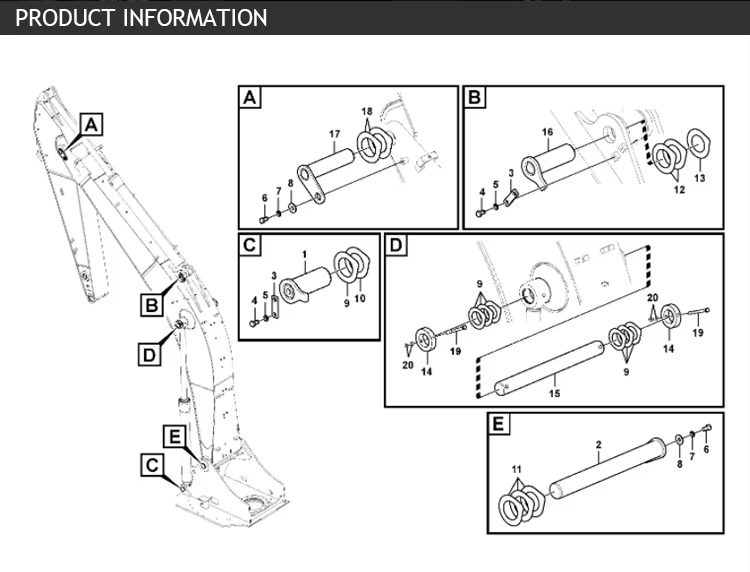

MYWAY Bushings for Excavator Boom

PC200-8 PC200-7 Excavator Bucket Boom Cylinder Arm Link Bushing 20y-70-32410

Lie-bherr 10408514 Excavators Diesel Engine Spare Parts Boom Root Connection Bushing for R964B R964C R966 Excavators

High-Quality Excavator Bushing for PC200/PC300/PC360 Boom Pins

Excavator Bucket Pin Excavator Boom Bushing Excavator Parts Bushing

192-0622: Cat® Hydraulic Cylinder Head Bushing

Bucket Boom Arm Pin and Bushings Excavator Bushings

Excavator Parts Excavator Boom Arm Bucket Bushing Excavator Bucket Ear and Bushing Bucket Ear Bushing

Wa380-6 Wheel Loader Spare Parts Boom Front Bushing 421-70-21240

Premium Hardened Steel Bucket Boom Arm Pin and Bushings

Ola Professional Manufacturer High Performance Excavator Bucket Boom Bushing

61q6-97040 61q697040 Bushing for Excavator R320LC-9 R330LC-9s Boom Bushing

Customizable Flanged Low Maintenance Replacement Parts Excavator Bucket Bushing

Optimized Replacement Excavator Boom & Bucket Bushings by MYWAY

Excavator Boom Bushings Applicable ModelInner Diameter*Outer Diameter*Height /mm

| KOMATSU | PC20 | PC30 | PC35 | PC40 | PC45 |

| PC60-1-3-5-6-7 | PC75 | PC100-3-5 | PC120-3-5 | PC150 | |

| PC200-1-3-5-6-7-8 | PC220-1-3-5-6 | PC300-1-3-5-6-7 | PC350 | PC400-3-5-6 | |

| CATERPILLAR | E55/E55B | E70/E70B | E110/E110B | E120/E120B | E180 |

| E215 | E225DLC | E235 | E240 | E300B | |

| E307 | E300J | E305 | E311/E312 | E320/E200B | |

| E322 | E324 | E325 | E330 | E339 | |

| E345 | E450 | ||||

| HITACHI | EX30 | EX40 | EX55 | EX60-1-2-3-5 | EX70 |

| EX100-1-3 | EX120-1-3-5 | EX150 | EX200-1-2-3-5-8 | EX220 | |

| EX230 | EX270 | EX300-1-2-3-5-6 | EX400-1-2-3-5 | EX600 | |

| UH043 | UH052 | UH053 | UH07 | UH081 | |

| UH082 | UH083 | ZAXIS 60 | ZAXIS 200-3-6 | ZAXIS 240 | |

| ZAXIS 270 | ZAXIS 330 | ZAXIS 360 | ZAXIS 450 | ZAXIS 870 | |

| ZAXIS 110 | ZAXIS 120 | ||||

| KATO | HD80 | HD140 | HD250 | HD400(HD450) | HD550 |

| HD700(HD770) | HD820(HD850) | HD880 | HD900 | HD1023 | |

| HD1220 | HD1250 | HD1430 | HD2053 | ||

| SUMITOMO | SH60 | SH70 | SH100 | SH120 | SH200 |

| SH210 | SH220 | SH280 | SH300 | SH320 | |

| SH350 | SH360 | SH400 | SH450 | SH460 | |

| LS2800FJ | S340 | S430 | |||

| KOBELCO | SK60 | SK70 | SK75 | SK07-N2 | SK07/2/7 |

| SK100 | SK120-3-5-6 | SK125 | SK160 | SK200-1-3-5-6-8 | |

| SK210 | SK220-3-6 | SK230 | SK250 | SK260 | |

| SK300-3-6 | SK320 | SK330 | SK400 | SK450 | |

| DAEWOO | DH55 | DH60 | DH80 | DH130 | DH150 |

| DH200 | DH220 | DH215 | DH220 | DH258 | |

| DH280 | DH300 | DH360 | DH370-9 | DH400 | |

| DH420 | DH500 | UH07 | K907C | ||

| HYUNDAI | R60 | R80 | R130-5-7 | R150 | R200 |

| R200-5 | R210 | R210-7 | R215-7 | R220-5 | |

| R225-7 | R260-5 | R265 | R290 | R300-5 | |

| R305 | R320 | R385 | R420 | R450-3-5 | |

| VOLVO | EC55B | EC140B | EC210 | EC240 | EC290B |

| EC290B PRIME | EC360 | EC460 | EC700 | ||

| KKUBOTA | U10 | U20 | U25 | KX35 | KX50 |

| KX61-2/-3 | KX71-2/-3 | KX85 | KX135 | KX155 | |

| KX161 | KX121 | ||||

| YUCHAI | YC35 | YC60 | YC85 | YC135 | |

| YANMAR | YM55 | YM75 | |||

| SAMSUNG | SE210LC | SE210LC | SE210LC | SE210LC | SE210LC |

| BOBCAT | E10 | E14 | E17 | X320 | X320 |

| TAKEUCHI | TB108 | TB016 | TB125 | TB145 | TB250 |

| MITSUBISH | MS110/MS120 | MS180 | MS230 | MS280 | |

| LOADER | 980C | 966D | 950E | 950C | 936E |

| ¢140*155*130 | ¢100*116*110 | ¢85*105*50 | ¢75*95*80 | ¢60*90*105 | |

| ¢140*160*200 | ¢100*116*100 | ¢85*100*105 | ¢75*90*95 | ¢60*80*80 | |

| ¢140*170*100 | ¢100*116*90 | ¢85*100*100 | ¢75*90*90 | ¢60*80*70 | |

| ¢130*154*130 | ¢100*115*145 | ¢85*100*90 | ¢75*90*80 | ¢60*80*65 | |

| ¢125*140*100 | ¢100*115*130 | ¢85*100*80 | ¢75*90*75 | ¢60*80*65/105/10 | |

| ¢125*140*90 | ¢100*115*120 | ¢85*100*70 | ¢75*90*70 | ¢60*80*60 | |

| ¢120*140*120 | ¢100*115*110 | ¢85*100*68 | ¢75*90*60 | ¢60*80*50 | |

| ¢120*140*110 | ¢100*115*100/5 | ¢85*100*60 | ¢75*85*90 | ¢60*75*95 | |

| ¢120*140*100 | ¢100*115*95 | ¢85*100*50 | ¢71*86*85 | ¢60*75*90 | |

| ¢120*140*90 | ¢100*115*90 | ¢85*95*100 | ¢71*86*80 | ¢60*75*80 | |

| ¢120*135*155 | ¢100*115*85 | ¢85*95*90 | ¢71*86*70 | ¢60*75*70/105 | |

| ¢120*135*120 | ¢100*115*80 | ¢80*120*100 | ¢71*86*65 | ¢60*75*75 | |

| ¢120*135*115 | ¢100*115*70 | ¢80*120*90 | ¢71*86*60 | ¢60*75*70 | |

| ¢120*135*110 | ¢100*115*65 | ¢80*110*95 | ¢71*86*50 | ¢60*75*65 | |

| ¢120*135*105 | ¢100*115*60 | ¢80*110*90 | ¢71*86*40 | ¢60*75*65/105/10 | |

| ¢120*135*100 | ¢100*115*35 | ¢80*110*80 | ¢70*100*95 | ¢60*75*82/129/110 | |

| ¢120*135*94 | ¢95*110*115 | ¢80*110*70 | ¢70*100*85 | ¢60*75*60 | |

| ¢120*135*78 | ¢90*130*100 | ¢80*110*95/130/10 | ¢70*95*80 | ¢60*75*60 | |

| ¢120*135*70 | ¢90*130*90 | ¢80*95*95/130/114 | ¢70*90*110 | ¢60*75*55 | |

| ¢120*135*48 | ¢90*125*110 | ¢80*95*87/154/137 | ¢70*90*100 | ¢60*75*50 | |

| ¢115*135*100 | ¢90*125*100 | ¢80*95*95/130/10 | ¢70*90*95 | ¢60*70*65 | |

| ¢115*135*95 | ¢90*120*120 | ¢80*110*85/165 | ¢70*90*90 | ¢55*80*70 | |

| ¢115*130*150 | ¢90*120*110 | ¢80*120*86/165 | ¢70*90*80 | ¢55*75*75 | |

| ¢115*130*140 | ¢90*120*110 | ¢80*105*100 | ¢70*90*70 | ¢55*75*70 | |

| ¢115*130*130 | ¢90*120*105/148/195/10 | ¢80*105*90 | ¢70*86*95 | ¢55*75*60 | |

| ¢110*145*150 | ¢90*120*100 | ¢80*105*80 | ¢70*85*146 | ¢55*70*80 | |

| ¢110*140*125 | ¢90*120*90 | ¢80*100*120 | ¢70*85*110 | ¢55*70*70 | |

| ¢110*135*125 | ¢90*120*80 | ¢80*100*100 | ¢70*85*100 | ¢55*70*65 | |

| ¢110*135*120 | ¢90*120*70 | ¢80*100*90/138/10 | ¢70*85*95 | ¢55*70*60 | |

| ¢110*135*110 | ¢90*115*100 | ¢80*100*90 | ¢70*85*90/130/10 | ¢55*70*50 | |

| ¢110*135*100 | ¢90*115*90 | ¢80*100*85 | ¢70*85*90 | ¢55*65*60 | |

| ¢110*130*120 | ¢90*115*80 | ¢80*100*80 | ¢70*85*85 | ¢55*65*50 | |

| ¢110*130*110 | ¢90*115*70 | ¢80*100*70 | ¢70*85*80 | ¢50*70*70 | |

| ¢110*130*100 | ¢90*110*110 | ¢80*100*60 | ¢70*85*75 | ¢50*70*60 | |

| ¢110*125*145 | ¢90*110*100 | ¢80*100*50 | ¢70*85*70 | ¢50*65*70 | |

| ¢110*125*140 | ¢90*110*90 | ¢80*96*100 | ¢70*85*65 | ¢50*65*65 | |

| ¢110*125*120 | ¢90*110*80 | ¢80*96*90 | ¢70*85*60 | ¢50*65*65/105/10 | |

| ¢110*125*115 | ¢90*106*110 | ¢80*95*120 | ¢70*85*50 | ¢50*65*60 | |

| ¢110*125*110 | ¢90*106*100 | ¢80*95*110 | ¢70*85*36 | ¢50*65*60 | |

| ¢110*125*100 | ¢90*106*90 | ¢80*95*105 | ¢70*80*90 | ¢50*65*55 | |

| ¢110*125*95 | ¢90*106*80 | ¢80*95*100 | ¢70*80*80 | ¢50*65*50 | |

| ¢110*125*90 | ¢90*106*70 | ¢80*95*95/3 | ¢70*80*70 | ¢50*60*60 | |

| ¢110*125*85 | ¢90*105*130 | ¢80*95*95 | ¢65*90*60 | ¢50*60*55 | |

| ¢110*125*80 | ¢90*105*125 | ¢80*95*90 | ¢65*85*80 | ¢50*60*50 | |

| ¢110*125*60 | ¢90*105*120 | ¢80*95*90/130/10 | ¢65*85*70 | ¢48*55*50 | |

| ¢105*125*140 | ¢90*105*110 | ¢80*95*85/4 | ¢65*85*65 | ¢48*55*30 | |

| ¢105*125*120 | ¢90*105*100 | ¢80*95*80 | ¢65*85*60 | ¢45*62*40 | |

| ¢105*125*90 | ¢90*105*95 | ¢80*95*75 | ¢65*80*105 | ¢45*60*60 | |

| ¢105*120*108 | ¢90*105*90 | ¢80*95*70 | ¢65*80*100 | ¢45*60*50 | |

| ¢105*120*100 | ¢90*105*90/135/10 | ¢80*95*65 | ¢65*80*90 | ¢45*60*45 | |

| ¢105*120*90 | ¢90*105*85 | ¢80*95*60 | ¢65*80*85 | ¢45*55*100 | |

| ¢100*130*130 | ¢90*105*80 | ¢80*95*55 | ¢65*80*80 | ¢45*55*60 | |

| ¢100*130*120 | ¢90*105*75 | ¢80*95*50 | ¢65*80*75 | ¢45*55*60/105/10 | |

| ¢100*130*110 | ¢90*105*70 | ¢80*95*45 | ¢65*80*70 | ¢45*55*50 | |

| ¢100*130*110/170/10 | ¢90*105*70 | ¢80*95*40 | ¢65*80*70/105/10 | ¢45*55*45/2 | |

| ¢100*130*100 | ¢90*105*65 | ¢80*95*36 | ¢65*80*65 | ¢45*55*40 | |

| ¢100*125*130 | ¢90*105*60 | ¢80*95*32 | ¢65*80*65 | ¢40*55*65 | |

| ¢100*125*120 | ¢90*105*55 | ¢80*90*105 | ¢65*80*60 | ¢40*55*50 | |

| ¢100*125*110 | ¢90*105*50 | ¢80*90*100 | ¢65*80*55 | ¢40*50*50 | |

| ¢100*125*100 | ¢90*100*105 | ¢80*90*90 | ¢65*80*50 | ¢40*50*45 | |

| ¢100*125*90 | ¢90*100*100 | ¢80*90*85 | ¢65*75*70 | ¢38*48*55 | |

| ¢100*120*135 | ¢90*100*90 | ¢80*90*80 | ¢65*75*65 | ¢35*50*60 | |

| ¢100*120*125 | ¢90*100*80 | ¢35*45*40 | |||

| ¢100*120*120 | ¢30*40*40 | ||||

| ¢100*120*115 | ¢30*38*35 | ||||

| ¢100*120*110 | ¢25*33*40 | ||||

| ¢100*120*100 | |||||

| ¢100*120*90 | |||||

| ¢100*120*85 S/F | |||||

| ¢100*120*80 |

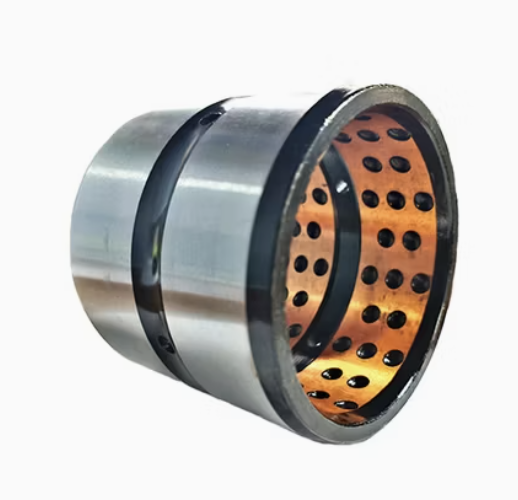

MYWAY’s excavator boom and bucket bushings are engineered from high-carbon steel and undergo a thorough hardening process, achieving a superior surface hardness of 48-52 HRC. This makes them an ideal solution for high-load, low-speed, and pivotal movement applications.

These precision-built sleeve bearings are critical for protecting your machine’s housings from premature wear caused by pin friction, effectively minimizing unplanned machine downtime and reducing long-term maintenance costs. To maintain optimal performance, we recommend daily or at least weekly greasing.

Key Features & Benefits:

Superior Wear & Abrasion Resistance: The thru-hardened construction ensures extended service life even in the most demanding conditions.

High Load-Bearing Capacity: Designed to withstand extreme pressures, providing reliable performance for your heavy-duty equipment.

Extended Operational Intervals: Robust design allows for long-lasting operation, enhancing productivity.

Cost-Effective Solution: Delivers outstanding durability and value, reducing the total cost of ownership.

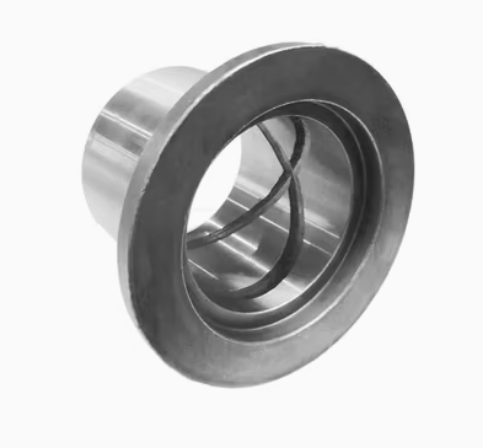

Our bushings can be customized to meet specific operational needs. We offer various internal groove patterns to ensure optimal lubricant distribution and facilitate the efficient removal of abrasive contaminants. Flanged bushings and washers are also available using the same advanced manufacturing technology.

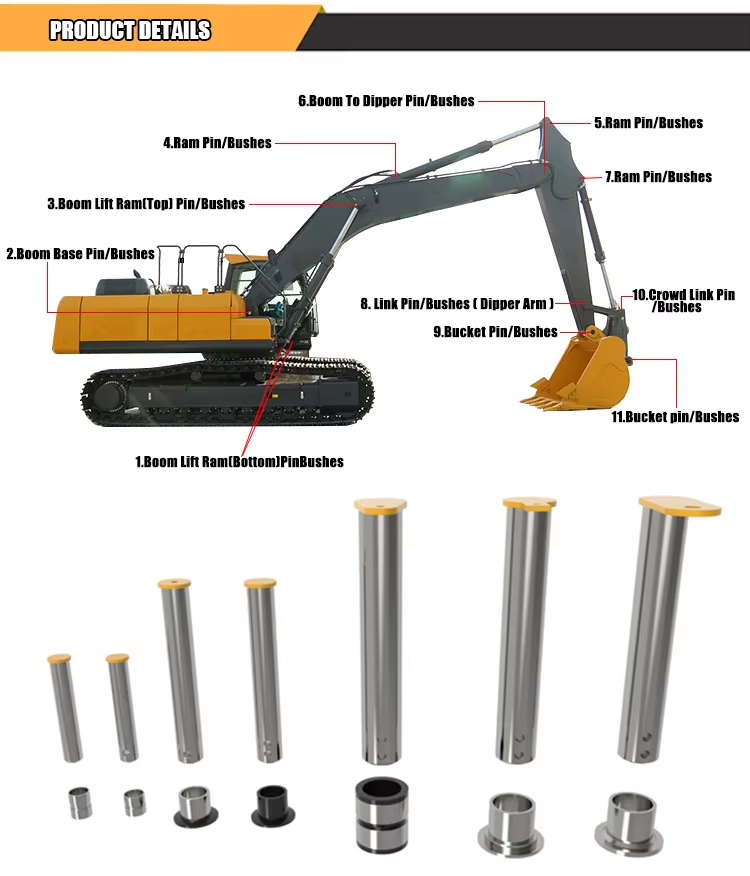

MYWAY provides a comprehensive range of compatible pins, bushes, and link assemblies designed to fit most common makes and models, including CAT, Hitachi, Komatsu, Kobelco, JCB, Daewoo, Volvo, and Hyundai.

10000+ Types of Excavator Boom Bushings – Contact Us for Details

Excavator Boom Bushings: The Critical Link to Power and Precision

The excavator boom is the machine’s primary lifting and digging arm, bearing the brunt of all excavation forces. At the very heart of this critical assembly are the excavator boom bushings. These deceptively simple components are the pivotal links between the boom, the excavator’s house, and the arm. They are fundamental to transferring hydraulic power into productive movement, ensuring smooth articulation, and absorbing catastrophic shock loads. By minimizing metal-on-metal friction and wear, high-quality boom bushings directly protect your most valuable assets: the boom itself and the main hydraulic cylinders, ultimately safeguarding your machine’s structural integrity, productivity, and resale value.

The Strategic Role of Bushings in the Boom Assembly

Boom bushings are not just simple sleeves; they are precision-engineered bearings installed at the boom’s most critical connection points.

Boom-to-House Connection (Foot Pin): This is the bushing where the boom connects to the excavator’s revolving house. It forms the primary pivot for the entire front attachment and must withstand immense multi-directional stresses from lifting and swinging.

Boom-to-Arm Connection (Front Pin): This bushing connects the boom to the stick (or arm). It is crucial for controlling the digging arc and is subjected to extreme impact forces during trenching and breakout.

A failure in any of these pivotal bushings can lead to catastrophic damage, including scored pins, cracked boom ears, and misalignment that strains hydraulic cylinders. This makes their condition and quality non-negotiable for machine health.

Identifying Worn Boom Bushings: Key Signs and Proactive Replacement

Ignoring worn boom bushings is a costly gamble. Proactive identification and replacement are essential for preventing downtime and expensive repairs.

Tell-tale Signs of Wear:

Excessive Free Play: Visible looseness or a “clunking” feeling in the boom joints during operation is a primary indicator.

Uncontrolled Movement: The boom or arm feels sloppy or drifts unexpectedly when handling loads.

Abnormal Noises: Audible knocking, grinding, or squeaking sounds from the boom pivot points during movement.

Visible Wear or Damage: Cracks, spalling, or significant wear patterns on the bushing’s surface.

The Critical Replacement Process:

Replacing boom bushings is a complex task that requires proper tools and expertise. The process typically involves:

Safe Disassembly: Carefully lowering the boom and disconnecting the arm and cylinders.

Pressing Out Pins and Bushings: Using hydraulic presses and specialized tools to remove the old, seized components without damaging the boom’s housing.

Precision Installation: Ensuring new bushings are pressed in square and to the correct tolerance. For a perfect fit and to ease installation, some manufacturers recommend specific techniques.

Proper Lubrication: Applying the correct grease to the new bushings and pins to ensure immediate protection and long service life.

Why Boom Bushings Demand the Highest Quality

The boom is the excavator’s backbone. Unlike other bushings, those in the boom are subjected to a combination of extreme static, dynamic, and shock loads. Therefore, the material and manufacturing quality are paramount.

Superior Materials: MYWAY boom bushings are made from hardened and tempered alloy steels,

ensuring high load-bearing capacity and excellent fatigue resistance.Advanced Heat Treatment: We employ controlled heat treatment processes to achieve a tough core and a hard, wear-resistant surface, providing an optimal balance of strength and durability.

Precision Machining: Each bushing is machined to exact OEM tolerances, guaranteeing a perfect fit that maintains alignment and distributes stress evenly.

The MYWAY Advantage: Engineered for Your Boom’s Demands

At MYWAY, we focus on the components that bear the greatest responsibility. Our Excavator Boom Bushings are not just replacements; they are engineered upgrades designed for reliability in the most demanding applications.

What Sets MYWAY Boom Bushings Apart:

Optimized for High Stress: Specifically engineered to handle the extreme bending moments and shock loads experienced at the boom pivots.

Extended Service Life: Our material science and manufacturing precision deliver a longer operational life, reducing your cost-per-hour and frequency of replacement.

Guaranteed Compatibility: We offer a comprehensive range of sizes and specifications to fit major brands like Caterpillar, Komatsu, Volvo, and Hitachi.

Custom Engineering Support: For specialized applications or unique machine models, our engineering team provides custom-designed boom bushing solutions to meet your exact performance requirements.

Don’t let a worn bushing compromise your machine’s backbone.

Discover MYWAY’s Precision-Engineered Boom Bushings →

Maximize Uptime and Protect Your Investment.

Contact MYWAY today for technical specifications, a competitive quote, or to consult with our experts on your specific needs.

10000+ Types of Excavator Boom Bushings – Contact Us for Details