MYWAY Bushings for Every Part of Your Excavators

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Bushings for Excavator Equalizer Bar & Suspension Linkage

| 195-50-00026 1955000026 | 143-3332 207-2684 494-6212 1433332 2072684 4946212 | 14X-50-00012 | 1409699 | 2226926 222-6926 |

| 195-50-00281 1955000281 | 154-50-20005 | 17M-50-00021 | 1409-698 222-6926 574-2845 127-8778 7T-1854 | 2818488 |

| 195-50-00092 1955000092 | 154-50-11115 | 17A-50-00111 17A5000111 | 140-9699 117-3355 117-3356 3P-5041 8E-4164 | 8G-4503 8E-0743 |

| 195-50-00182 1955000182 | 175-50-00023 | 17A-50-00020 | 141-4690 1414690 | 8P-1865 |

| 195-50-41112 195-50-00281 D375 | 175-50-00025 195-50-00080 195-50-00281 | 17A-50-12112 17A5012112 | 1774651 | 3T-7785 140-9701 207-2683 495-0327 |

| 198-50-00114 | 175-71-21182 | 123-8686 | 2072683 207-2683 | 3T7785 1409701 2072683 4950327 |

| GP 195-50-41112 | 281-8488 2818488 | 124-5947 | 207-2684 | 1409698 2226926 5742845 7T1854 |

| 2072683 207-2683 CAT 320D 336D | 281-8488 281-8481 281-8490 201-2076 2818488 | 131-7184 | 2223682 | 1409699 1173355 1173356 3P5041 8E4164 |

| 137-6718 123-8686 238-5082 177-4651 124-5947 131-7184 | 281-8491 441-4771 | 1409698 | 2260462 226-0462 | 2818481 2818490 2012076 |

10000+ Types of Excavator Equalizer Bar & Suspension Linkages – Contact Us for Details

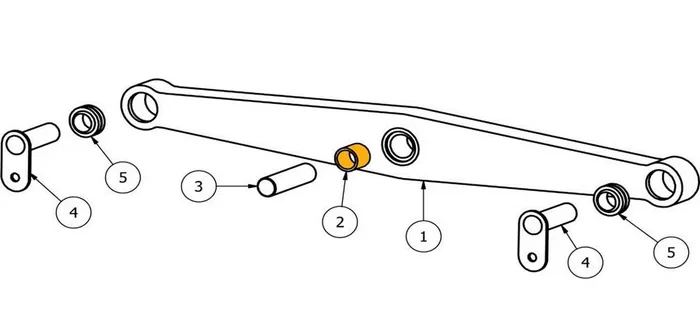

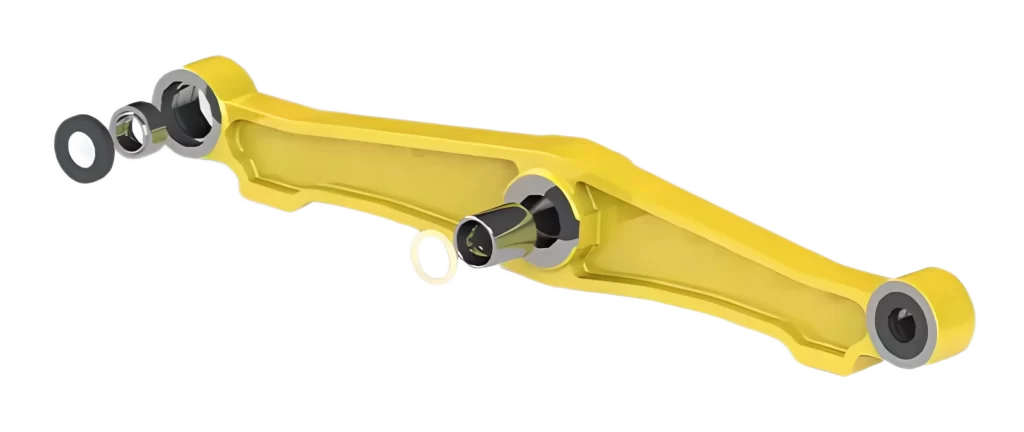

Bushings for Excavator Equalizer Bar & Suspension Linkage

In heavy earth-moving machines such as excavators, the pivot points and linkages are subject to extremely high shock loads, lateral forces and continuous oscillation. One critical area is the connection between the upper structure and the undercarriage — often via the so-called “equalizer bar” (swing circle) and its associated suspension linkage. The bushings installed at these connecting points play a vital role in ensuring smooth movement, absorbing abuse and extending machine life.

What is the Equalizer Bar & Suspension Linkage?

The “equalizer bar” (also called the “swing circle bar” in some machines) links the upper structure (house) of the excavator with the undercarriage/tracks. It allows the machine house to rotate while maintaining the structural alignment and distributing the loads. The suspension linkage may refer to the connecting arms, pins and supports that help manage the motion, absorb shock and maintain alignment in rough terrain.

Why Bushings Matter in This Application

At each pivot or link point, the bushings serve multiple functions:

They act as bearing surfaces between the pin (shaft) and the housing, reducing wear on expensive structural components. sibo.eu+2gfmparts.com+2

They absorb lateral and shock loads, helping reduce vibration, chatter and noise — all of which increase fatigue and maintenance costs.

They maintain proper alignment of the linkage under massive repetitive loading, which improves machine stability and service life.

They simplify maintenance: replacing a worn bushing is much cheaper and faster than repairing a damaged structural link or undercarriage.

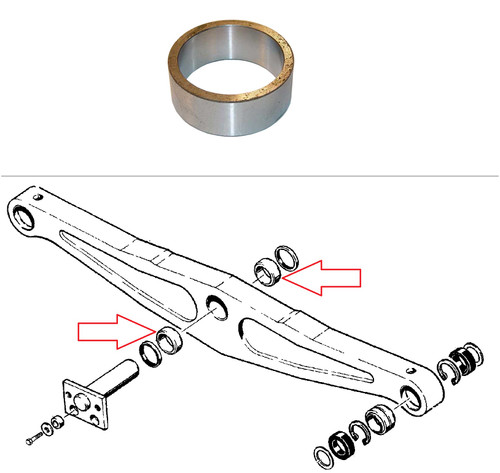

Typical Bushing Types Used for the Equalizer Bar & Linkage

For this heavy duty pivot environment, a few bushing types dominate:

Heavy‐Duty Steel Bushings – These are steel sleeves, sometimes hardened or alloyed, designed for high load, low speed, oscillating motion. They may require regular lubrication.

Keywords: steel sleeve bushings, high load excavator bushings.Flanged Bushings – These bushings include a flange (a radial plate) to control axial movement or provide extra bearing surface and positioning. Useful when the load direction includes axial thrust.

Keywords: flanged bushings excavator, axial load bushings.Self-Lubricating Bushings – These are variants that incorporate a low-friction liner (such as PTFE or oil-impregnated bronze) to reduce the need for external grease, particularly useful when maintenance access is limited or machine downtime is costly.

Material and Manufacturing Considerations

Many excavator bushings are made of high-carbon steel or alloy steel (for example 40Cr) and then hardened (e.g., 48-52 HRC) to resist wear. peersparts.com+1

Good manufacturing practice includes precise tolerances for the inner diameter (ID) and outer diameter (OD) so the bushing fits tightly in the housing, minimizing play which can accelerate wear.

Depending on the design, lubrication grooves or grease holes may be included, especially in pin/bushing systems subject to high oscillation.

When self-lubricating bushings are used, the liner material must withstand the oscillating motion and load cycles without excessive creep or deformation.

Common Failure Modes & Maintenance Tips

Failure Modes:

Excessive play (clearance) between pin and bushing ➜ leads to impact loading, noise, accelerated wear.

Lack of lubrication (for non self-lubricating types) ➜ rapid wear or seizure.

Misalignment or improper installation ➜ uneven load distribution, premature failure.

Corrosion or contamination (water, dirt) ➜ accelerated wear of both bushing and pin surfaces.

Maintenance Tips:

Inspect regular wear pattern around the equalizer bar linkage, check for looseness or visible damage.

Ensure lubrication schedule is strictly maintained; if self-lubricating bushings are used, verify they’re appropriate for the application and load.

When installing a new bushing, ensure proper interference or press-fit as recommended by the manufacturer.

Replace bushings in matched pairs (or whole linkage sets) if wear is advanced, to restore alignment and uniform behavior.

Why Quality Bushings Lead to Lower Costs and Longer Life

Using high-quality bushings in the equalizer bar & suspension linkage yields benefits:

Stabilises the motion of the upper structure and undercarriage, reducing shock transmission and reducing operator fatigue and machine stress.

Minimises downtime for repairs: if wear is contained to bushings, replacement is quicker and cheaper than replacing structural links or pins.

Improves resale value and machine performance, because the machine remains within tolerance and operates smoothly.

Enhances safety: worn pivot linkages can cause track misalignment, uneven rotation, and even structural failure.

Summary

In summary, the bushings in the equalizer bar and suspension linkage of an excavator are a small but critical component. Choosing the right bushing type—whether heavy-duty steel, flanged, or self-lubricating—and maintaining them properly can deliver big returns in machine performance, lower maintenance costs and longer service intervals.

When you’re specifying or replacing bushings in the equalizer bar / swing circle linkage system, keep these key search terms in mind for sourcing:

“excavator bushings”, “equalizer bar bushings”, “swing circle linkage bushings”, “heavy-duty steel bushings”, “self-lubricating bushings excavator”, “link pin bushes excavator”.

10000+ Types of Excavator Equalizer Bar & Suspension Linkages – Contact Us for Details