MYWAY Bushings for Every Part of Your Excavators

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Bushings for Excavator Track Roller

| Track Link Assembly | |||

| Model | Ktm Part Number | Link | Pitch |

| CAT330/330GC | W216C/CG | 45/49 | 216 |

| E345/345B | W216MD/MI | 53/49 | 216 |

| E330/330B, 330BL/BLN | W216MH | 45,48 | 216 |

| PC400-3/5, LC-3/5, HD5 | W216MD | 49,53/52,52 | 216 |

| PC300-6/7, 350-6/7, 360-6/7 | W216ME | 45 | 216 |

| EX400-2/3/5, 450-5 | W216MD | 49 | 216 |

| EX300-5/6, 330-5/6 | W216ME | 45 | 216 |

| ZX370/370MTH/450H | W216MD | 49 | 216 |

| ZX270/330/350/360 | W216ME | 45 | 216 |

| DH400LC-5, 450LC-5, 470LC-5 | W216MI | 53 | 216 |

| Sprocket | |||

| Model | Ktm Part Number | Weight (KG) | Teeth & Bore Diameter (mm) |

| PC1250-7 | SW280K | 182.7 | 25*38*843 |

| PC800 | SW260K | 142 | 25*25*790 |

| PC650-8 | SW228K6 | 94.4 | 23*34*615 |

| PC450-6-7 | SW228K | 63.6 | 21*26*565 |

| PC360-8 | SW216K3-8 | 66.3 | 21*24*525 |

| PC360 | SW216K3-6 | 64.8 | 21*20*525 |

| PC240 | SW190K | 38.7 | 21*20*475 |

| PC120/130 SY135 | SW175K | 30.9 | 21*15*324 |

| PC60-6-7 SY75 | SW154K | 24.4 | 21*12*265 |

| PC60-5 HD250 | SW135K6 | 23.1 | 23*12*265 |

| Idler | |||

| Model | Ktm Part Number | Weight (KG) | |

| PC1250-7 | IW280K | 875 | |

| PC800 | IW260K | 510 | |

| PC650-8 | IW228K6 | 368 | |

| PC450 | IW228K4 | 276 | |

| PC360 | IW216K | 198 | |

| PC240 | IW190K | 108 | |

| PC120/130 | IW175K | 86 | |

| EX1200-6 | IW280H | 745 | |

| EX1200-5 | IW260H2 | 706 | |

| ZX870 | IW260H1 | 488 | |

| Carrier Roller | |||

| Model | Ktm Part Number | Weight (KG) | |

| PC1250-7 | CW280K | 89 | |

| PC800-7 | CW260K1 | 63 | |

| PC360-7, PC450-7 | CW216K37 | 34.8 | |

| PC360-8 Ø53.5 | CW216K38 | 28.1 | |

| PC240-8 | CW190K8 | 13.5 | |

| PC200-7 | CW190K7 | 16.2 | |

| PC200-5, R225-7 | CW190K5 | 21.6 | |

| PC120-5 | CW175K | 12.7 | |

| PC60-5 | CW135K6 | 12 | |

| ZX1200-6, ZX870 | CW280H | 87 | |

| Track Roller | |||

| Model | Ktm Part Number | Weight (KG) | |

| PC1250 | RW280K | 192 | |

| PC800 | RW260K | 148 | |

| PC400/450 | RW228K | 77.7 | |

| PC300/360, EC290 | RW216K3 | 56.7 | |

| PC240 | RW190K | 40.5 | |

| PC120, SY135 | RW175K | 23.1 | |

| PC60-5 | RW135K6 | 15.7 | |

| PC60-6 | RW154K6 | 13.5 | |

| ZX870 | RW260H1 | 143 | |

| EX400 | RW216H | 82.4 |

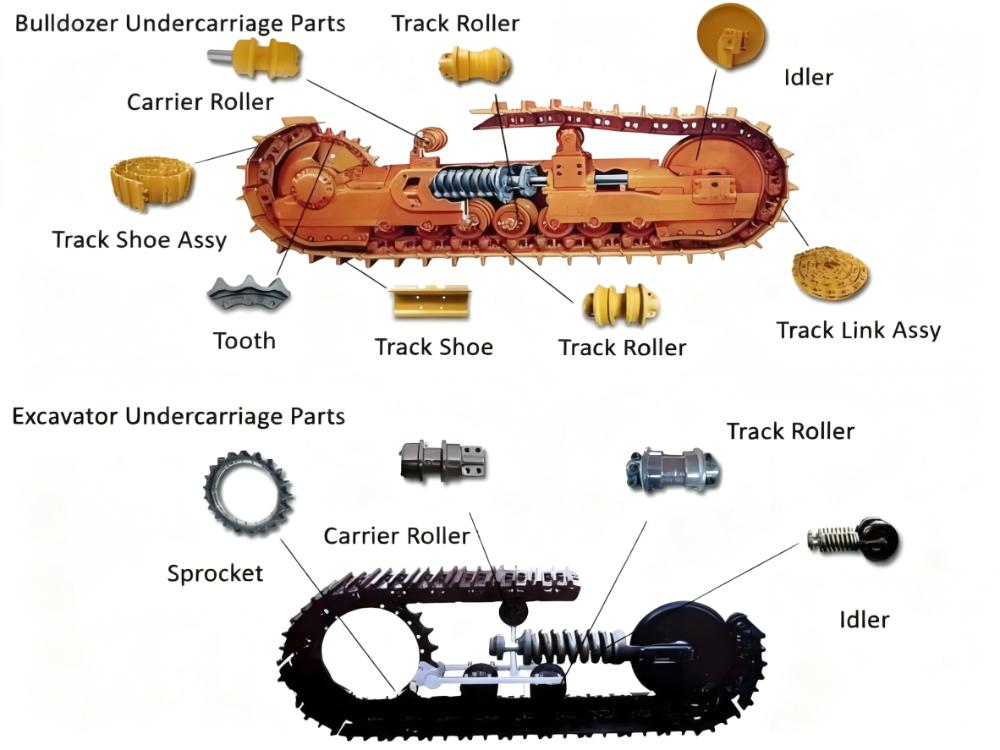

10000+ Types of Excavator Track Rollers – Contact Us for Details

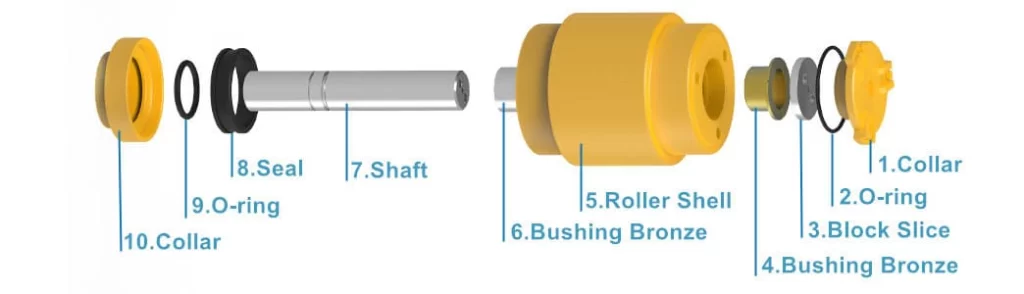

A Closer Look at Track Roller Bushings

While the powerful engines of mining trucks and bulldozers often steal the spotlight, their true ability to move mountains lies in their robust undercarriage systems. At the heart of these systems are critical components known as track roller bushings, which play a pivotal role in translating engine power into reliable motion under the most extreme conditions.

What is a Track Roller Bushing?

A track roller bushing is a heavy-duty sleeve bearing fitted within the track rollers of crawler vehicles like excavators, bulldozers, and mining trucks. The roller itself supports the machine’s immense weight and rolls along the track. The bushing, working inside the roller, ensures smooth rotation while withstanding tremendous shock loads, abrasion, and contamination from mud, dust, and water.

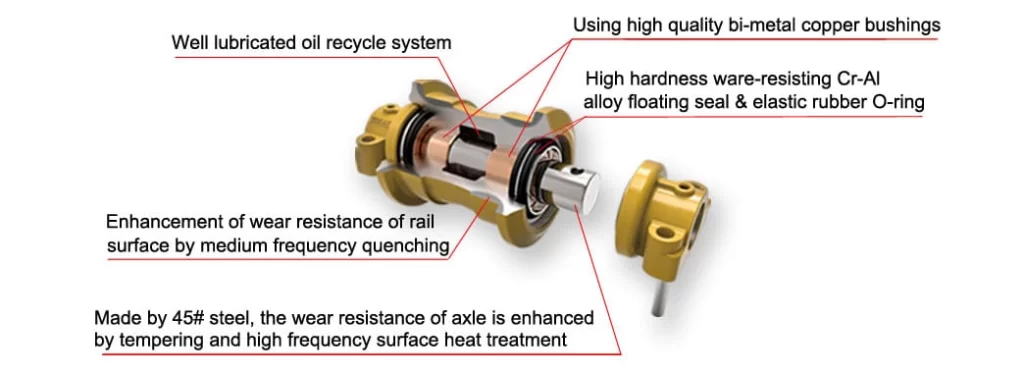

Why is Its Material So Critical?

Given the harsh operating environment, the material of the track roller bushing directly determines the equipment’s uptime and maintenance costs. The industry standard is to use advanced bimetal materials, which combine the strengths of two different metals to create a superior product.

A typical high-performance track roller bushing features a three-layer structure:

Steel Backing: Provides exceptional mechanical strength and high load-carrying capacity. It acts as a rigid support, ensuring the bushing maintains its shape under extreme pressure.

Sintered Bronze Layer: Bonded to the steel backing, this layer offers excellent wear resistance and outstanding fatigue properties. Its porous nature is ideal for retaining lubrication, which is vital for longevity.

Surface Plating (Copper/Tin): A thin plating provides an additional layer of corrosion resistance and further enhances the surface’s anti-friction properties.

3. Structural Design Innovations

Komatsu’s rotating bushing solutions include:

A parallel-link undercarriage system for small and medium equipment, allowing bushings to rotate freely during sprocket engagement.

A dual-bushing link assembly for large equipment, which adds a rotating bushing to the traditional fixed bushing design.

Similarly, Case’s Max-Life system incorporates a hardened rotating bushing that covers the fixed bushing, achieving up to twice the lifespan of standard systems under specific conditions.

These technological advances have fundamentally transformed maintenance practices for modern undercarriage systems, significantly reducing the need for traditional bushing rotation. Caterpillar’s System One further optimizes bushing compatibility with the entire undercarriage through self-contained pin-and-bushing assemblies and a center-track idler design, enabling uniform wear and long-term reliable operation.

The MYWAY Advantage: Engineering for Extreme Duty

At MYWAY, we don’t just supply bushings; we provide engineered solutions. Our track roller bushings are manufactured to the highest standards, precisely meeting the demanding requirements of the mining and construction industries.

How MYWAY Bushings Match Your Needs:

Unmatched Durability: We use premium Bimetal Bushing to ensure our bushings have high load-bearing capacity and excellent fatigue resistance, perfect for supporting the world’s heaviest machines.

Superior Wear Resistance: The optimized sintered bronze layer guarantees extended service life, even in abrasive environments full of dust and mud.

Corrosion Protection: Our standard copper or tin plating effectively fights corrosion, a key threat in wet and variable working conditions.

Customized Solutions: We understand that one size does not fit all. MYWAY offers customized dimensions and material selections to perfectly match your specific equipment model and application challenges.

Upgrade your equipment with MYWAY reliability. Contact us today for a quote and expert technical support.