MYWAY Bushings for Every Part of Your Excavators

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Bushings for Excavator Undercarriage

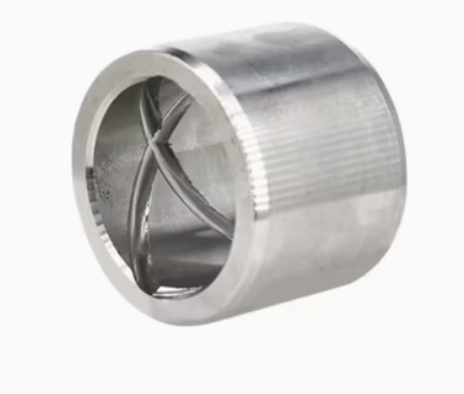

Durable Heat Treated Undercarriage Use Bucket Bushing

Model NO. Spiral oil channel Bucket bushing Condition New Product Name Bushing Sleeve Bush Types Flange Features Wear Resistance Lubricating Carbon Standard DIN1494 Surface Treatment Phosphating Black Product Shape Customized Bushing Material Steel Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet Specification Customization Trademark Sennai Origin China

Durable Heat Treated Undercarriage Use Bucket Bushing

Model NO. bucket pin bushing Certification ISO9001: 2000 Condition New Product Excavator Bucket Pin and Bushing Product Type Bucket Pin and Bushing Description Excavator Bucket Pins and Bushings Material 45# 40cr Excavator Brand Weld on Bucket Pin and Bushing Excavator Type Crawler Excavator Related Parts Excavator Bucket, Weld-on Bucket Hook Related Product Bucket Teeth, Side Cutter, Cutting Edge

NB1116-3 --- undercarriage Spring and Equalizer Bushing

Nylon Bushing for 3" Wide Springs Outer Diameter: 1-1/16" Inner Diameter: 7/8" Length of Bushing: 2-15/16" Nylon Bushing

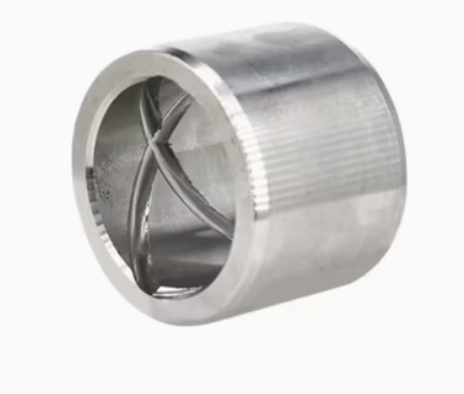

Sintered Brass Bushing Excavator Bushings Excavator Loader Undercarriage Parts Bucket Pin Bushing

Type Bushing Application Excavator Condition New Video Outgoing-Inspection Provided Applicable Industries Building Material Shops Marketing Type New Product 2020 Color Custuestomer's Request Showroom Location None Material 40cr Machinery Test Report Provided Transport Package Wooden Box Specification Standard Production Capacity 10000 Piece/Pieces Per Month

Excavator Undercarriage Parts Bucket Bush Bucket Bronze Bushing

Sand Core Type Resin Sand Core Application Machinery Parts Machining CNC Machining Material Copper and Copper Alloy Surface Treatment Polishing Surface Roughness Ra0.05 Standard AISI Certification CE, ISO 9001:2000, ISO 9001:2008 Bronze and Copper Available Tin Bronze, Lead Bronze, Aluminum Bronze, Aluminum Transport Package According to Customer's Requirement Specification According to customer's technical drawig Trademark CXYS Origin China Production Capacity 100000PCS/ Month

High Strength Precision Made Undercarriage Parts Bucket Bushing

Model NO. Spiral oil channel Bucket bushing Condition New Product Name Bushing Sleeve Bush Types Flange Features Wear Resistance Lubricating Carbon Standard DIN1494 Surface Treatment Phosphating Black Product Shape Customized Bushing Material Steel Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet Specification Customization Origin China Packaging & Delivery Package Size 6.30cm * 6.30cm * 5.70cm Package Gross Weight 0.060kg

High Strength Durable Undercarriage Excavator Bucket Bushing

Model NO. Spiral oil channel Bucket bushing Condition New Product Name Bushing Sleeve Bush Types Flange Features Wear Resistance Lubricating Carbon Standard DIN1494 Surface Treatment Phosphating Black Product Shape Customized Bushing Material Steel Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet Specification Customization Trademark Sennai Origin China Package Size 6.30cm * 6.30cm * 5.70cm Package Gross Weight 0.060kg

Excavator Undercarriage Parts Bucket Bush, Bucket Pin Bushing Cobalt Alloy

Model NO. D50.4/D35.18*H50.7 Process Powder Metallurgy Color Silver Grey Density 8.15-8.8g/Cm Mateial Cobalt Based Alloy Custom Design Accept Hardness 37-55HRC Application Oil and Gas Industry Property Wear and Corrosion Resistance Chemical Composition Cobalt,Chrom,Nickel Ect. Transport Package Cardboard Box, Plywood Box Origin Liaoning, China Production Capacity 10000 Piece/Pieces Per Month Bucket Bushing

Ola High Strength Excavator Undercarriage Parts 40cr Excavator Bucket Bushing

Model NO. BB57 Type Bearing Application Excavator Certification CE, ISO9001: 2000 Condition New Product Name Bucket Bushing Keywords Excavator Bucket Bushing Color Silver, Black or Customized Height Optional Width Optional Material 40cr Hardness HRC48-52 Technique Forging Finish Smooth Process Forging /Casting Size Standard or Customized Quality 100% Tested MOQ 1 Piece Logo Accept OEM OEM Services Provided Transport Package Pallet or Customized Specification Customized

Excavator Bushings Excavator Loader Undercarriage Parts Bucket Bushing

Model NO. Spiral oil channel Bucket Bushing Condition New Product Name Bushing Sleeve Bush Types Flange Features Wear Resistance Lubricating Carbon Standard DIN1494 Surface Treatment Phosphating Black Product Shape Customized Bushing Material Steel Transport Package Anti-Rust Paper, Carton, Wood Case or Pallet Specification Customization

Undercarriage Parts Bucket Pins and Bushings Xs50 Xs115 Xs250

Model NO. XS50 XS115 XS250 Type Undercarriage Parts Track Roller Application Excavator Certification CE, ISO9001: 2000 Condition New Product Name Excavator Bucket Tooth Pin and Bushing Material 40cr Machine Type Forging Steel, Casting Color Black , Yellow , as Requirement Request Against The Customer's Drawing or Part Number Surface Hardness Polishing, Machining, Plating, Heat Treatment, Pai Grade 4.8, 6.8, 8.8, 10.9, 12.9 Finish Black,Zinc Plated,Copper Plating Surface Treatment Polishing Transport Package Wooden Cartons Specification Forging steel, Casting 40CR

Undercarriage Parts Bucket Pins and Bushings Xs50 Xs115 Xs250

Model NO. XS50 XS115 XS250 Type Undercarriage Parts Track Roller Application Excavator Certification CE, ISO9001: 2000 Condition New Product Name Excavator Bucket Tooth Pin and Bushing Material 40cr Machine Type Forging Steel, Casting Color Black , Yellow , as Requirement Request Against The Customer's Drawing or Part Number Surface Hardness Polishing, Machining, Plating, Heat Treatment, Pai Grade 4.8, 6.8, 8.8, 10.9, 12.9 Finish Black,Zinc Plated,Copper Plating Surface Treatment Polishing Transport Package Wooden Cartons Specification Forging steel, Casting 40CR

| Top Sale Track Pin And Bushing Products Specification | |||

| Outer Diameter*Inner Diameter*Height /mm | |||

| 32*19.6*65 | 59*37.4*150 | 50.8*34.2*125 | 46 * 67 * 175 |

| 32*20*52 | 59.3*37.5*150 | 50.8*34*125 | 46 * 66.8 * 170 |

| 35.3*23.5*59 | 59.3*39*129 | 51*34.5*125 | 46 * 67 * 170 |

| 35.3*23*62 | 59.3*38.6*130 | 51.3*34.8*125 | 76*51*162 |

| 35.3*23*65 | 59.8*38.6*130 | 51.5*35*125 | 85.35*58.6*203 |

| 35*23.5*77 | 59.3*38.6*135 | 53*34*130 | |

| 35.3*23*76 | 59.3*38.6*138 | 53.8*34*110 | 162*74.63*79.3*49 |

| 35.3*23.5*80 | 59.3*38.6*139 | 54*37.5*130 | 81.5(100)(94)/79.3*74.6*48.5*180/172 |

| 37*25.6*93/88 | 59.3*38.8*142/145 | 54*37.3*140 | 81.6(99)*74.6*48.1*172 |

| 37*25.6*97 | 59.3*38.8*145 | 54.3*37.5*150 | 73(100)*66.8*45.2*160/170 |

| 40.5*29*95 | 59.3*38.8*146(59.3*38.5*145) | 55*38.5*150 | 53.9*50.8*33.9*105 |

| 40.5*29*85 | 59.3*38.7*150 | 55.3*38.8*150 | 69.3(95)*66.8*45*156 |

| 40*24*80 | 59.5*39*150 | 55.5*39*150 | 64.5(90)*61.3*37*155 |

| 39.3*23*80 | 59.8*39*150 | 55.9*33.9*140 | 65(90)*59.3*38.6*142 |

| 41.3*24.5*86 | 63.8*42.7*142 | 56*34*113 | 65(90)*63.5*38.6*142 |

| 41.3*25*92 | 64*43*160 | 58.8*37.2*125 | 74.6(108)*71.6*48*175 |

| 41.3*25.6*93/88 | 64*43*158 | 58.8*37*128 | 77.1(124)*76*51*203 |

| 41.3*25.6*97 | 66.7*45.2*143.5 | 58.8*37*126/130 | 72.7(95)*66.8*45.2*156 |

| 41.5*25.1*92 | 66.8*45.3*149 | 58.8*37.2*129.4 | 73(104)*66.8*45.2*160 |

| 41.8*25.3*92 | 66.8*45.3*157/9 | 58.8*37*135 | 65(80)*59.3*38.6*142 |

| 42*25.5*92 | 67*46*159 | 58.8*37*138 | 74(102)*71.6*47.5*170 |

| 45*30.6*114/99 | 66.7*45.2*165 | 58.8*37.2*142 | 60.8(66)*56*36.8*120 |

| 46.3*31*105 | 66.8*45.2*160(66.8*45*160) | 58.8*37.2*145 | 79.3*74.6*48.3*172/204 |

| 46.3*31*110 | 66.7*45.2*175 | 85*80.3*51.6*210/230 | |

| 46.3*31*109 | 68*46.7*155 | 48.3*31*92.5 | 71.2*47.5*170 |

| 46.5*31*110 | 68*47*175 | 48.2*32.5*84 | 71.6*48*175 |

| 47.5*28.5*110 | 68.3*47.2*175 | 50.5*34*125 | 71.6*48*181 |

| 47*30*104 | 68.5*47.4*175 | 50.6*34*110 | 77*49*195/77.3*49.5*195 |

| 47.3*31*116 | 71.3*47.6*154 | 50.8*34*120 | 46 * 66.8 * 175 |

| 47.5*31*116 | 71.3*48.3*157 | 47.8*31*116 | 71.4*47.8*160 |

| Note: We can also produce pins and bushes according to your coming sample or drawing. | |||

10000+ Types of Excavator Undercarriage Bushings – Contact Us for Details

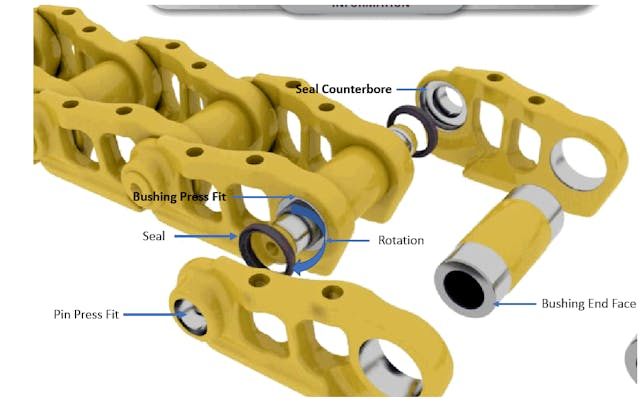

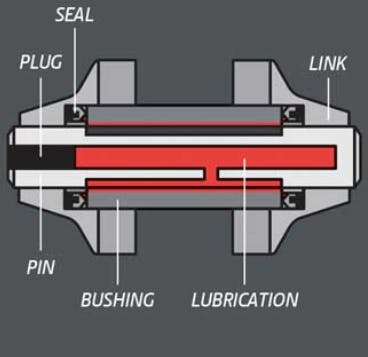

Bushing Systems for Tracked Equipment Undercarriages

As a critical wear component in tracked equipment undercarriages, bushing innovation directly impacts service life and maintenance costs. Current industry advancements primarily focus on three core directions:

1. Sealed Lubrication System Innovations

Modern sealed and lubricated track systems establish a continuous oil film between the pins and bushings, significantly reducing wear. Industry leaders like Caterpillar employ proprietary sealing technology and synthetic lubricants, reducing friction at sealing interfaces by up to 50%. Synthetic oils not only minimize adhesion between seals and bushings but also resist breakdown, maintaining high lubrication quality over extended periods and effectively extending bushing service life.

2. Breakthroughs in Surface Treatment Technologies

John Deere’s SC-2 coating technology fuses a specialized coating onto the bushing surface at temperatures exceeding 2000°C, achieving a hardness more than three times that of conventional hardened steel. This innovation can double bushing lifespan and, under certain conditions, eliminate the need for bushing rotation maintenance entirely.

3. Structural Design Innovations

Komatsu’s rotating bushing solutions include:

A parallel-link undercarriage system for small and medium equipment, allowing bushings to rotate freely during sprocket engagement.

A dual-bushing link assembly for large equipment, which adds a rotating bushing to the traditional fixed bushing design.

Similarly, Case’s Max-Life system incorporates a hardened rotating bushing that covers the fixed bushing, achieving up to twice the lifespan of standard systems under specific conditions.

These technological advances have fundamentally transformed maintenance practices for modern undercarriage systems, significantly reducing the need for traditional bushing rotation. Caterpillar’s System One further optimizes bushing compatibility with the entire undercarriage through self-contained pin-and-bushing assemblies and a center-track idler design, enabling uniform wear and long-term reliable operation.

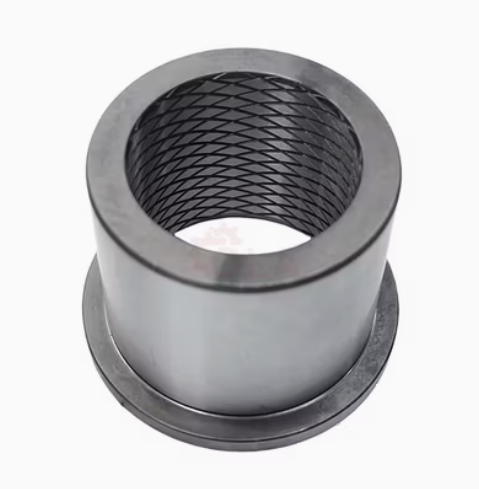

Bushing Solutions for Excavator Undercarriage Systems

In excavator undercarriage systems, components such as track rollers, idlers, and track links are critical friction points, demanding exceptional wear resistance, load capacity, and impact resistance. The table below summarizes commonly used bushing types, industry references, and MYWAY’s corresponding solutions:

| Component | Core Requirements & Operating Conditions | Common Bushing Types & Industry References | MYWAY Solution |

|---|---|---|---|

| Track Rollers | Supports machine weight and withstands heavy impact loads; requires high wear resistance and lubrication. Standard JB/T 2985-2001 outlines technical requirements, emphasizing high hardenability, toughness, wear resistance, and lubrication. | Bimetal bushings are widely used (e.g., brands like “Tengong” offer such products). Hardened steel bushings (e.g., 45# steel, 40Cr) are also common. | MYWAY Bimetal Bushings, offering excellent wear resistance suitable for high-load and intermittent heavy-duty conditions. |

| Idlers | Supports track rails and limits sag; relatively lower loads but requires reliable wear resistance. May use floating seal structures with bushings. | Bimetal or bronze bushings, depending on load conditions. | MYWAY Bimetal or Bronze Bushings, providing stable low-friction and maintenance-free operation. |

| Track Links | Forms track joints with pins; directly subjected to wear and impact, requiring extreme wear and compressive strength. | Pin bushings, often made of powder metallurgy (e.g., iron-copper-carbon systems) or bimetal materials for high wear resistance. | MYWAY Powder Metallurgy Bushings or Bimetal Bushings, delivering high compressive strength and wear resistance. |

Selection and Collaboration Recommendations

In addition to standard product solutions, MYWAY offers support in the following areas:

Customized Design: We provide bushing solutions tailored to specific equipment operating conditions and installation space requirements.

Material and Technical Support: Our engineering team offers material selection guidance and technical consulting, such as determining optimal interference fits, clearance fits, and other critical parameters.

We are confident that MYWAY’s expertise in material technology and product reliability will bring significant value to your excavator undercarriage systems, ensuring enhanced performance and durability.

Looking for high-performance bushing solutions?

Contact MYWAY to explore how our advanced bushing technologies can optimize your equipment’s performance and reduce lifecycle costs.