Home » Flange Bushings

MYWAY Flange Bushings Product List

What is Flange Bushing?

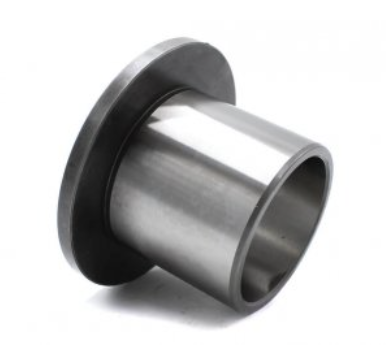

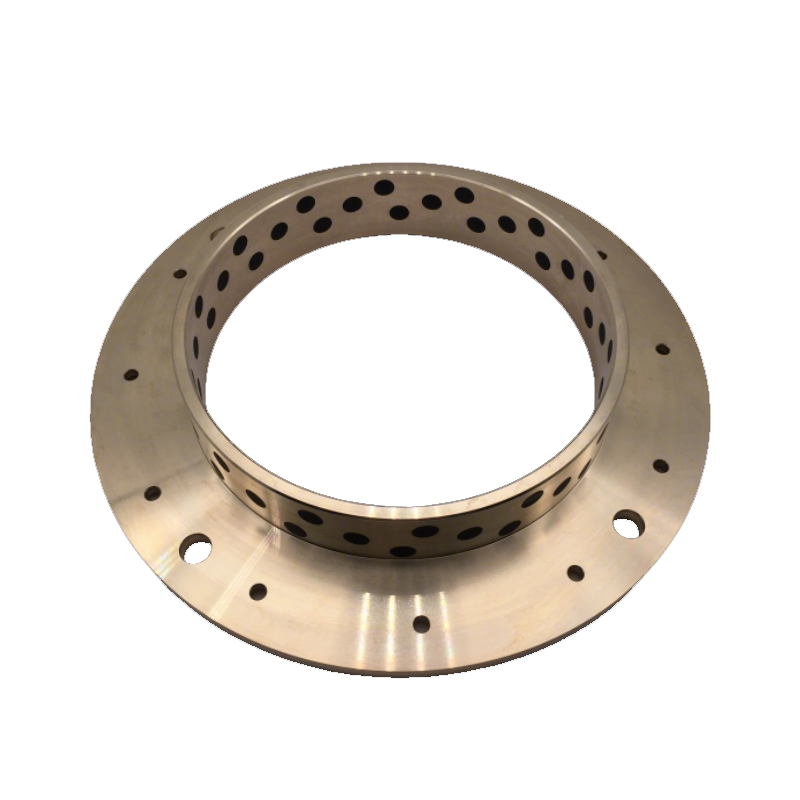

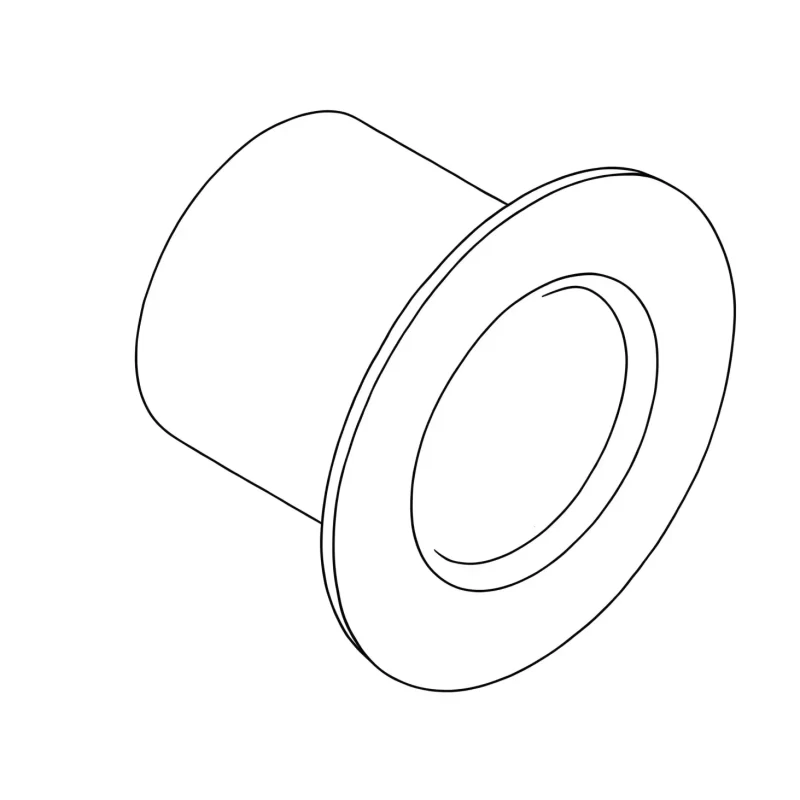

A flange bushing, also known as a flanged sleeve bearing, is a cylindrical bearing component with an integral radial flange at one end. This design serves a dual purpose: the sleeve supports and reduces friction for a rotating or sliding shaft, while the projecting flange provides axial location and handles thrust loads. Characterized by this one-piece, flanged construction, it acts as a compact, self-retaining unit that simplifies assembly by preventing axial movement within the housing. Its ability to manage combined radial and axial forces in a single, cost-effective part makes it a fundamental mechanical element in countless applications across robotics, automotive systems, agricultural machinery, and conveyor equipment.

Based on the differences in material composition and application characteristics of our product series, we offer components in standard materials and standard specifications. Additionally, we can develop and design customized, non-standard products according to the specific purposes and operating conditions provided by our customers. Should you have any needs, please feel free to contact us at any time.

The Complete Guide to Flange Bushings: Materials, Applications & How to Choose

Introduction: What is a Flange Bushing?

If you’ve ever looked at a piece of machinery and wondered how shafts stay perfectly in place while rotating under heavy loads, the answer often involves a small but mighty component: the flange bushing.

At its core, a flange bushing (also commonly called a flange bearing) is a type of plain bearing that provides a wear-resistant surface for a rotating or sliding shaft. Its defining feature is an integrated flange (a projecting rim or lip) at one end. This simple design is its superpower: the cylindrical body supports radial loads (forces perpendicular to the shaft), while the flange handles axial (thrust) loads (forces parallel to the shaft) and acts as a built-in stopper for precise positioning. In essence, it’s a compact, two-in-one solution for load management and alignment.

Flange bushings are the unsung heroes in countless applications, from the robotic arm in an automated factory to the heavy-duty pivot point in agricultural equipment. For engineers and procurement managers, selecting the right flange bushing is critical for ensuring machine reliability, reducing maintenance costs, and preventing costly downtime. This guide will break down everything you need to know.

Core Functions and Key Advantages

Why choose a flanged bushing over other bearing types? The benefits are significant for design and operation:

Dual Load Management: The primary advantage is its ability to handle combined radial and axial loads simultaneously with a single, compact unit. This eliminates the need for separate radial bearings and thrust washers.

Simplified Assembly and Precision Alignment: The flange provides a positive stop, making installation easier and ensuring the bushing is accurately located within its housing. This built-in positioning is crucial for maintaining alignment and simplifying design.

Space Efficiency: By integrating two functions into one part, flange bushings offer a highly compact design solution, ideal for applications where space is at a premium.

Cost-Effectiveness and Maintenance Reduction: Often more economical than complex rolling element bearings, they can also be manufactured from self-lubricating materials. This “fit-and-forget” feature dramatically reduces maintenance needs and lifecycle costs.

Operational Benefits: As sliding bearings, they operate quietly, dampen vibrations effectively, and, with the right material choice, can withstand corrosive or contaminated environments where other bearings would fail.

Material Breakdown: Choosing the Right Foundation

The performance of a flange bushing is largely dictated by its material. Each material family offers distinct advantages for different operating conditions.

| Material Type | Key Characteristics & Advantages | Ideal For / Applications | Important Considerations |

|---|---|---|---|

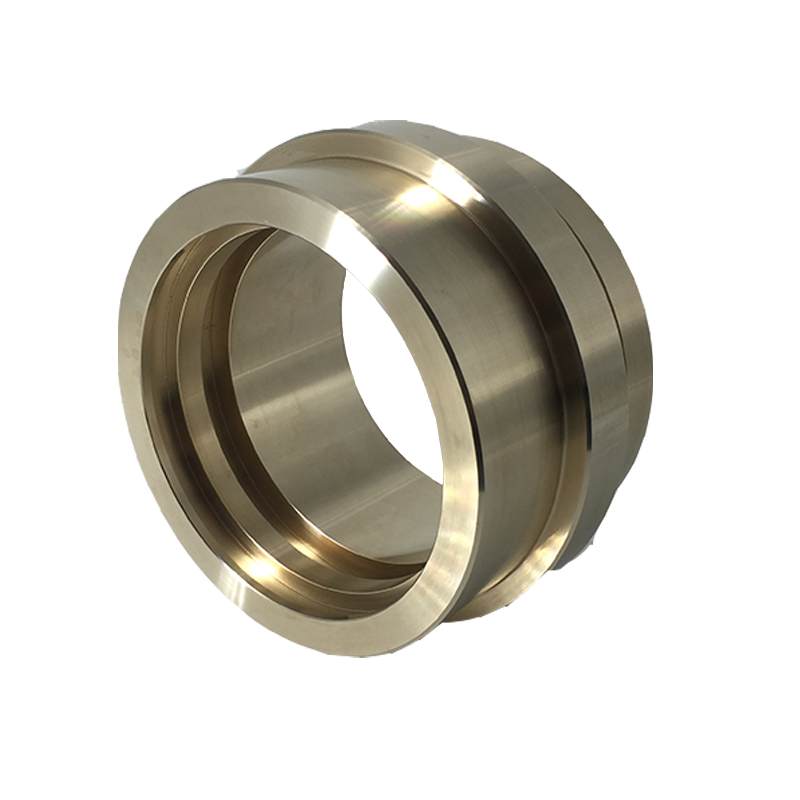

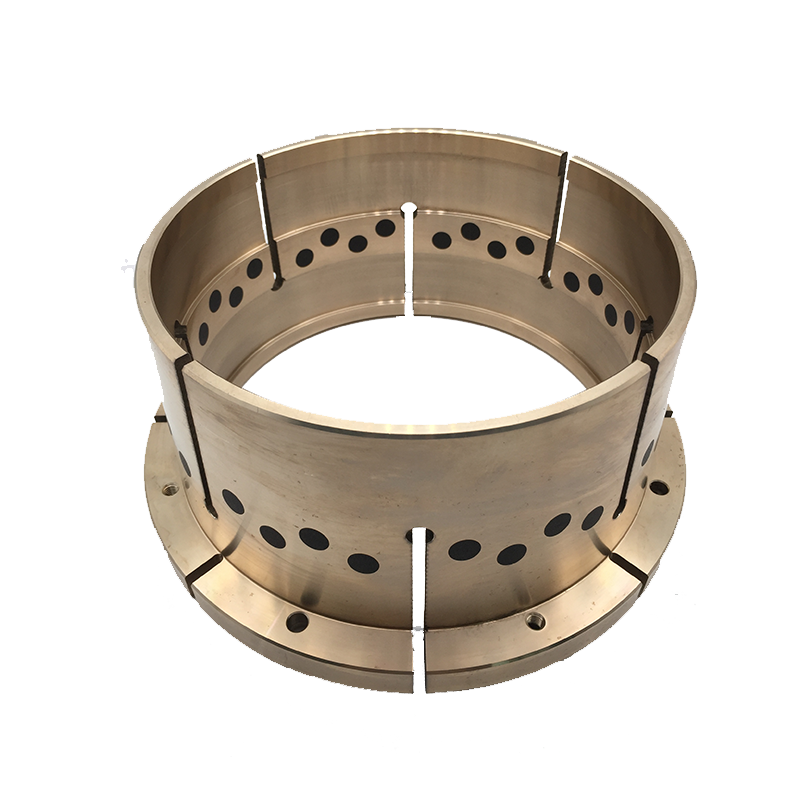

| Bronze (Oil-Impregnated) | Self-lubricating, good wear resistance, moderate load/speed capability, good heat dissipation. | General-purpose industrial applications (pumps, conveyors), situations where re-lubrication is difficult. | Requires proper run-in; performance limited by the embedded oil’s temperature range. |

| Engineering Plastics (PTFE, Nylon, POM) | Inherently low friction, corrosion/chemical resistant, lightweight, quiet, and often self-lubricating. | Food & beverage machinery, chemical processing, clean rooms, low-load/high-speed applications. | Lower load capacity and temperature limits than metals; can be subject to thermal expansion. |

| Steel with Composite Liner | High structural strength, excellent wear resistance, low friction from the liner, handles high loads. | Heavy-duty, high-wear applications in construction, mining, and heavy machinery. | Higher cost; requires precise installation; the liner properties dictate chemical/temp limits. |

| Stainless Steel | Excellent corrosion resistance, good strength, and hygiene. | Marine environments, pharmaceutical, food processing, and chemical industries. | Higher cost than standard steel; load capacity may be lower than some alloy steels. |

Industry Applications: Where Flange Bushings Excel

The versatility of flange bushings makes them indispensable across a broad industrial spectrum:

- Automation & Robotics: Providing precise, smooth motion in linear guides, actuator joints, and pick-and-place arms.

- Agricultural Machinery: Withstanding harsh, dirty environments in pivot points, linkages, and steering mechanisms of tractors and harvesters.

- Food & Beverage Processing: Self-lubricating plastic or stainless-steel bushings are used in conveyor rollers and mixer shafts, meeting hygiene standards with minimal maintenance.

- Packaging & Printing Machinery: Ensuring smooth operation and precise registration in high-cycle machines.

- Automotive: Found in suspension linkages, pedal assemblies, and accessory components, where they absorb road shocks and vibrations.

- General Industrial Machinery: A backbone component in pumps, fans, textile machinery, and conveyor systems of all kinds.

Critical Selection Criteria: A Buyer’s Checklist

Choosing the correct flange bushing involves more than just matching a catalog number. Consider these key factors:

- Load Analysis: Calculate both the radial and axial loads your application will generate. Don’t forget to account for shock loads and use an appropriate safety factor.

- Environmental Conditions: Will the bushing be exposed to water, chemicals, extreme temperatures, or abrasive contaminants? The answers directly guide material selection (e.g., stainless steel for corrosion, plastic for chemicals).

- Speed and Movement: Is the motion continuous rotation, slow oscillation, or linear? Speed affects heat generation and wear rate, influencing material and lubrication choice.

- Lubrication Strategy: Can you maintain a regular lubrication schedule? If not, a self-lubricating bushing (oil-impregnated bronze or plastic) is essential to prevent premature failure and reduce maintenance overhead.

- Installation & Housing Design: A bushing is only as good as its installation. The housing bore must be accurately sized, perpendicular, and free of burrs to ensure even load distribution and prevent premature failure from misalignment.

Why Choose MYWAY Bushings? Your Partner for Reliable Motion

At MYWAY, we don’t just sell components; we provide engineered solutions for demanding applications. We understand the critical role a reliable bushing plays in your machine’s uptime and productivity.

- Engineered Material Expertise: We offer a comprehensive range of materials, from high-performance self-lubricating composites for maintenance-free operation to durable bronze alloys for heavy-load scenarios. Our technical team can help you select the optimal material for your specific combination of load, speed, and environment.

- Precision Manufacturing for Reliability: Every MYWAY bushing is manufactured to exacting tolerances, ensuring consistent quality, a perfect fit, and long, predictable service life. This precision translates directly into smoother operation and less wear on your valuable shafts.

- Customization Capability: Need a non-standard size, a special flange configuration, or a unique material property? Our manufacturing flexibility allows us to produce custom flange bushings tailored to your exact design requirements, helping you solve unique engineering challenges.

- Global Supply Chain & Expert Support: We combine deep industry knowledge with a responsive supply chain. Our experts are ready to provide technical support, from the selection phase through to installation guidance, ensuring you get the right part and the best performance.

Ready to optimize your design with the right flange bushing?

Don’t let bearing failure dictate your maintenance schedule. Contact MYWAY today for a technical consultation or a competitive quote. Let our expertise help you build more reliable, efficient, and maintenance-friendly machinery.

FAQ: Your Flange Bushing Questions Answered

Q: What’s the difference between a plain bushing and a flange bushing?

A: A plain bushing (or sleeve bearing) is a simple cylinder designed to handle radial loads only. A flange bushing has an added flange that allows it to also resist axial (thrust) loads and provide positive axial location, making it a more versatile component.

Q: Are self-lubricating flange bushings as strong as metal ones?

A: Advanced engineering plastics and composite materials (like metal-backed polymer liners) offer extremely high wear resistance and load capacity. While traditional plastics have limits, modern self-lubricating composites are engineered for heavy-duty applications and often outperform metals where lubrication is a challenge.

Q: How do I install a flange bushing correctly to avoid damage?

A: Key steps include: ensuring the housing hole is the correct size and clean, pressing the bushing in evenly (not hammering), and making sure the flange sits flush against the mounting surface without obstruction. Always refer to the manufacturer’s installation specifications.

Q: Can I get custom-sized flange bushings for a prototype or special machine?

A: Yes. Reputable manufacturers like MYWAY often provide custom sizing and manufacturing services. This is common for prototypes, legacy equipment repairs, or specialized OEM applications where standard sizes are not a perfect fit.

Q: My application is in a wet environment. What material should I use?

A: For wet or corrosive environments, stainless steel or certain corrosion-resistant engineering plastics (like POM or PTFE-based composites) are excellent choices. They provide long service life without rust or degradation.