The Complete Value Package in Construction Machinery: Myway High-Performance Bushings

If you are engaged in the construction machinery manufacturing industry, such as excavator, bulldozer, tractor, car, etc., then bushings must be one of your indispensable helpers.

- Having passed ISO9001 certification

- Various Types, Wide Applications

- Replacement for Famous Brands

- High-quality Materials ensure Performance

- The Friction Coefficient Range is 0.06-0.12μ.

Home » Construction Equipment Bushing

Bushings for Construction Machinery

- Application Site: upper arm, lower arm, pit connection.

- Features: resistant to mud and sand wear, high load bearing, easy to replace.

- Bushing Types: bronze bushing, self-lubricating bushing (SF-1, JF).

- Application Site: bucket hinge, lift arm.

- Features: withstanding frequent lifts and shocks.

- Bushing Types: FB090 bronze bushing, self lubricating bushing.

- Application Site: track wheels and steering joints.

- Features: Long service life, capable of high loads.

- Bushing Types: JDB Solid lubricated bushings, bimetallic bushings.

- Application Site: Eccentric shafts, spindle assemblies.

- Features: Suitable for high temperature and high pressure, high speed friction conditions.

- Bushing Types: Bronze bushings, graphite embedded bushings.

Application Site: Eccentric shafts and spindle assemblies in crane mechanisms.

• Features: Engineered for high-temperature, high-pressure, and high-speed friction conditions.

• Bushing Types: Bronze bushings and graphite embedded bushings.

Wear Bushing Drilling Rig

- Application Site: Eccentric shafts, spindle assemblies.

- Features: Suitable for high temperature and high pressure, high speed friction conditions.

- Bushing Types: Bronze bushings, graphite embedded bushings.

Features of Myway Bushings

Wide Applications

Bushings are needed to provide protection whenever there is a scenario where two parts rub against each other, especially in construction, agriculture and automotive.

Comprehensive Variety

As a mature bushing production factory, Myway can provide you with various types of bushings, perfectly suitable for Caterpillar, Komatsu, Volvo CE, Sandvik, Metso and other brands.

Favorable Price

With mature supply chain management and large-scale production, Myway achieves highly competitive price positioning, while ensuring product performance and quality.

Reliable Quality

Having obtained ISO, CE, IATF, UL and other authoritative certification, Myway designs and manufactures bushings to exacting standards, making them quality assured.

Accurate Parameters

Myway utilizes fully automated equipment to fabricate bushings, ensuring consistency from batch to batch. The size tolerance of our bushings is no more than 0.2 mm.

High Performance

Based on high quality raw materials, standardized production and quality control, Myway bearings are wear-resistant, quiet and have a long service life.

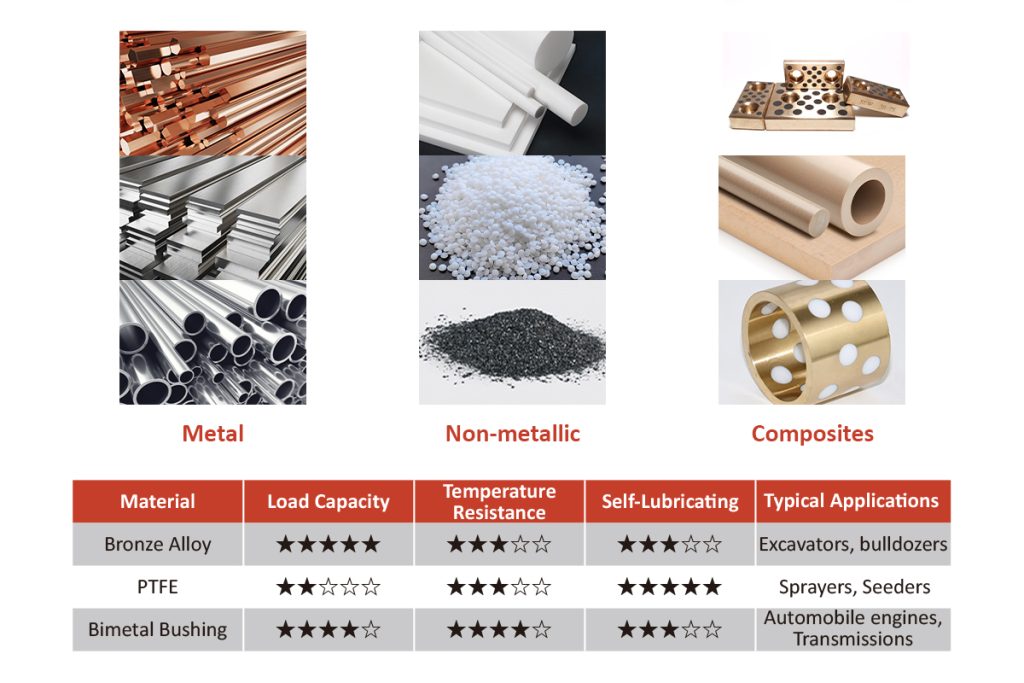

Main Materials of Bushings

You can rest assured that the raw materials used by Myway are sourced from reliable suppliers to ensure the quality and performance of bushings.

- Metals: Carbon steel; brass; high-lead brass; copper alloys such as tin bronze and aluminum bronze; stainless steel 304/316; cast iron; aluminum alloys such as duralumin and wrought aluminum.

- Non-metallic: Plastics including PTFE and POM, of which PTFE has a very low coefficient of friction and is resistant to wear and corrosion; POM is self-lubricating and rigid. In addition, graphite is often embedded as a lubricant in the metal or plastic matrix.

- Composites: Metal matrix composites, such as copper alloys inlaid with graphite / PTFE; fiber reinforced composites, such as glass fiber / carbon fiber reinforced plastics (FRP / CFRP).

How to Choose the Suitable Bushings

- Load Considerations: For light-duty applications (agricultural seeders), you can choose economical self-lubricating plastic (PTFE/POM) or powder metallurgy bushings. For heavy-duty machines like excavators or bulldozers, we recommend that you use copper alloy or bimetallic bushings for higher load carrying capacity.

- Environmental Requirements: In dusty/muddy environments (construction machinery), self-lubricating bushings (SF-1/JF) should be selected to minimize maintenance. In high temperature/corrosive environments (automobile engines), stainless steel or graphite-coated copper alloy bushings is a brilliant choice..

- Equipment Compatibility: Myway bushings are an exact match to OEM specifications (e.g., Caterpillar Cat. No. XYZ, Komatsu Part No. ABC) and are a drop-in replacement. If standard sizes don’t fit, we can provide a customized solution to meet your requirements.