Recent Posts

Phosphor Bronze: The Material Powering Modern Engineering and Why It's Critical for Your Next Project

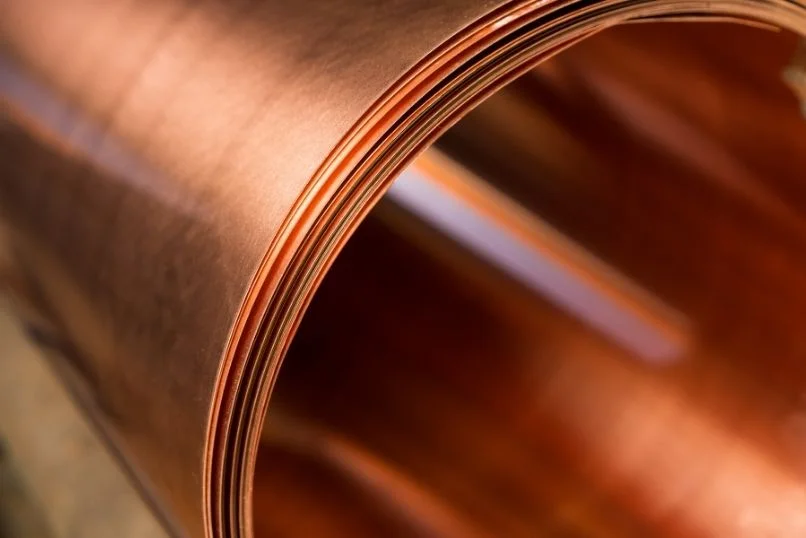

In an era defined by demanding applications—from the rapid acceleration of electric vehicles to the relentless forces in offshore wind turbines—engineers are constantly pushing materials to their limits. One alloy consistently rises to these challenges, forming the backbone of critical components where failure is not an option: phosphor bronze. This isn’t just another copper alloy; it’s a precision-engineered material where every percentage point of tin and phosphorus translates directly into performance, durability, and cost savings in your applications.

The global copper alloys market, valued at a staggering $81.5 billion in 2025, is propelled by this demand for high-performance materials. It’s projected to grow at a robust 6.7% annually, driven significantly by the electrification of transport and renewable energy infrastructure. In this landscape, understanding phosphor bronze isn’t just technical knowledge—it’s a competitive advantage for anyone specifying components for machinery, automotive systems, or industrial equipment.

Table of Contents

1. Decoding the DNA of Performance: The C51000 Alloy

At the heart of many high-demand applications lies the UNS C51000 alloy, a premier grade of phosphor bronze. Its strength stems from a meticulously balanced chemical composition:

Copper (Cu): The foundation, providing inherent corrosion resistance and excellent formability.

Tin (Sn): The primary strengthener (4.2-5.8%). It dissolves into the copper matrix, significantly boosting tensile strength, hardness, and corrosion resistance, especially against seawater and industrial atmospheres.

Phosphorus (P): The multi-functional enhancer (0.03-0.35%). It acts as a powerful deoxidizer during casting, ensuring a sound, high-quality microstructure. The residual phosphorus forms hard, wear-resistant particles, increasing stiffness and fatigue strength.

What truly sets phosphor bronze apart is how this composition translates into a unique and reliable set of mechanical properties, which can be precisely tuned through temper (cold working and annealing).

Mechanical Properties of UNS C51000 (Phosphor Bronze) by Temper

The values below are indicative for flat products and demonstrate the property range achievable.

| Temper | Condition | Tensile Strength (MPa) | Yield Strength (MPa) | Elongation (%) | Key Application Fit |

|---|---|---|---|---|---|

| OS050 | Annealed (Soft) | ~324 | ~131 | 64% | Ideal for complex forming and deep drawing. |

| H04 | Hard | ~579 | Not Specified | 7% | Excellent for springs, bushings, and parts requiring high strength and good wear resistance. |

| H08 | Spring | ~710 | Not Specified | 3% | Used for electrical contacts, high-stress springs, and components demanding exceptional fatigue life. |

This tunability is governed by standards like ASTM B159/B159M, which ensures material consistency for wire, and ASTM B103/B139 for sheet, strip, and bar products. It means you can specify the exact grade (like C51000, C52100, C52400) and temper (from soft O61 to extra spring H10) to match your component’s life cycle stresses perfectly.

2. The Unsung Hero: Phosphor Bronze in Action

You likely encounter phosphor bronze daily without knowing it. Its signature blend of high strength, excellent fatigue resistance, superior corrosion resistance, and good electrical conductivity makes it indispensable across industries.

Electrical & Electronics: Its reliable performance as a spring material is legendary. It’s the force behind reliable connections in electrical connectors, switches, relay contacts, and fuse clips, where it must maintain constant pressure over millions of cycles without relaxing.

Automotive & Transportation: From traditional engine bushings and bearings to critical battery terminal connectors and charging port components in EVs, phosphor bronze handles vibration, wear, and electrical loads with ease.

Industrial Machinery: It is a preferred material for gears, wear plates, valve components, and pump parts exposed to corrosive fluids or demanding mechanical service.

Understanding a material’s limits is as crucial as knowing its strengths. While phosphor bronze offers exceptional wear resistance, certain extreme applications—high loads, oscillating movements, extreme temperatures, or environments where lubrication is impossible—demand an evolutionary step forward.

This is where MYWAY Self-Lubricating Bushings and Bearings provide the engineered solution. We start with the inherent advantages of high-strength, corrosion-resistant bronze as a robust structural base. Onto this foundation, we integrate advanced composite materials to solve the lubrication challenge permanently.

The MYWAY MW-1 Bushing features a sophisticated multi-layer design:

A Self-Lubricating Liner (0.01-0.03mm): A modified PTFE and lead mixture forms a permanent, low-friction transfer film on the shaft during operation, eliminating metal-to-metal contact and preventing stick-slip motion.

A Porous Copper Powder Layer (0.20-0.30mm): This layer is critical. It acts as a reservoir for the liner material, ensures a permanent bond to the substrate, and significantly boosts the carrying capacity and thermal conductivity of the bushing, dissipating heat quickly.

The High-Strength Bronze Backing (0.7~2.3mm): This provides the structural integrity, high load-bearing capacity, and corrosion resistance expected from a premium bronze component.

4. Why Specify a MYWAY Bushing for Your Next Design?

Maintenance-Free Operation: Eliminate downtime and costs associated with lubrication schedules. Ideal for sealed-for-life designs or hard-to-reach locations.

Exceptional Performance in Harsh Conditions: Perform reliably in dusty, wet, or chemically aggressive environments where grease would wash away or attract contaminants.

Handles Complex Movements: Excel under oscillating, rotating, or linear sliding motions, even where lubrication starvation is a risk.

Proven in Demanding Sectors: Our components are specified for construction machinery, agricultural equipment, offshore applications, and heavy industrial automation.

5. Engineer with Confidence, Specify with MYWAY

Phosphor bronze represents the pinnacle of traditional alloy performance. Yet, the future of industrial components lies in intelligent material hybrids that solve systemic problems like maintenance and lubrication failure.

At MYWAY, we don’t just supply parts; we provide reliable motion solutions. By leveraging our expertise in advanced self-lubricating composites bonded to high-performance backers like phosphor bronze, we help you build machines that are more durable, efficient, and cost-effective.

Ready to eliminate lubrication points and boost reliability in your design? Contact our technical sales team today for a consultation or to request samples. Let’s engineer a solution that pushes the boundaries of what your application can achieve.

6. Frequently Asked Questions (FAQs)

Q: Is phosphor bronze suitable for marine environments?

A: Yes, it is an excellent choice. The tin content in phosphor bronze provides outstanding resistance to corrosion from seawater and salt spray, making it a classic material for marine hardware, pump components, and shipbuilding applications.

Q: Can phosphor bronze be welded or soldered?

A: It has good joining characteristics. Phosphor bronze can be successfully brazed and soldered. Certain grades and tempers can also be welded using appropriate techniques like gas-shielded arc welding, though careful procedure selection is necessary to preserve its properties.

Q: How does phosphor bronze compare to brass for mechanical parts?

A: Phosphor bronze is generally stronger, more wear-resistant, and offers better fatigue and corrosion resistance. Brass (a copper-zinc alloy) may be more easily machined and is less expensive, but for parts under cyclic loading (like springs) or in corrosive service, phosphor bronze is the superior engineering choice.

Q: My application involves slow movement under very high load with no lubrication. Will a standard bronze bushing work?

A: This is a classic scenario where a standard bushing might fail due to seizing or rapid wear. A MYWAY self-lubricating bushing is specifically engineered for this challenge. The embedded solid lubricants provide a consistent, low-friction interface even under extreme pressure (P.V. values), ensuring smooth operation and long service life without maintenance.

Q: How do I request a quote or get engineering support for a custom bushing?

A: We specialize in custom solutions. Simply contact our engineering team with your application parameters: operating loads, motions, temperatures, environmental conditions, and space constraints. We will recommend the optimal material combination and design for your specific needs.

100000+ Types of Bushings – Contact Us for Details