MYWAY Plastic Bushing

Meeting the Needs of All Your Transmission Parts

China Manufacturer of Precision Bushings & Bearings: Custom CNC Machining, Cost-Effective Performance.

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Plastic Compound Bushing

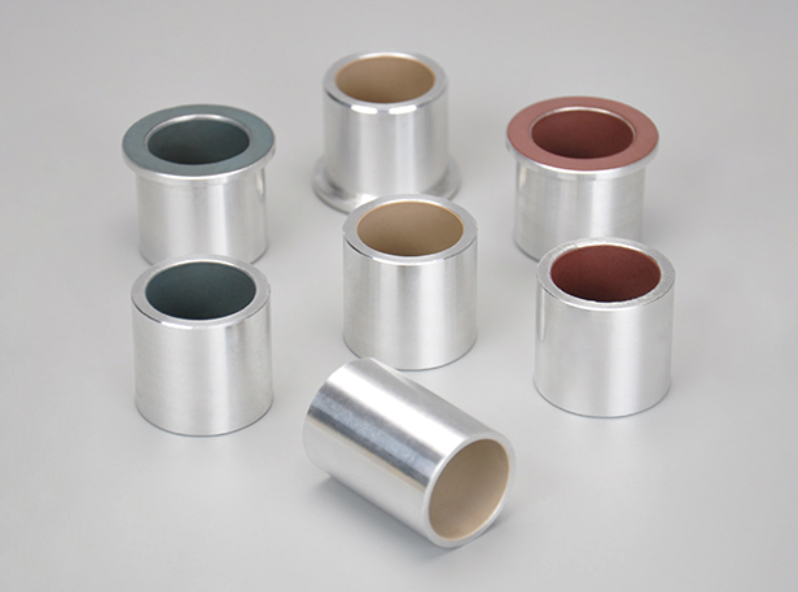

Plastic Bushing

What is Plastic Bushing?

Plastic bushings are injection-molded from high-performance engineering plastics to offer a cost-effective alternative to metal bushings in light-load applications. Their key advantages include:

Lightweight & Self-Lubricating: Reduce component inertia and often enable maintenance-free, oil-free operation.

Corrosion Resistant: Immune to rust and resistant to many chemicals.

Quiet & Protective: Dampen vibration, reduce noise, and are gentle on shafts.

Ideal for applications in food packaging, automotive interiors, office equipment, and appliances where weight, corrosion, noise, and cost are critical factors.

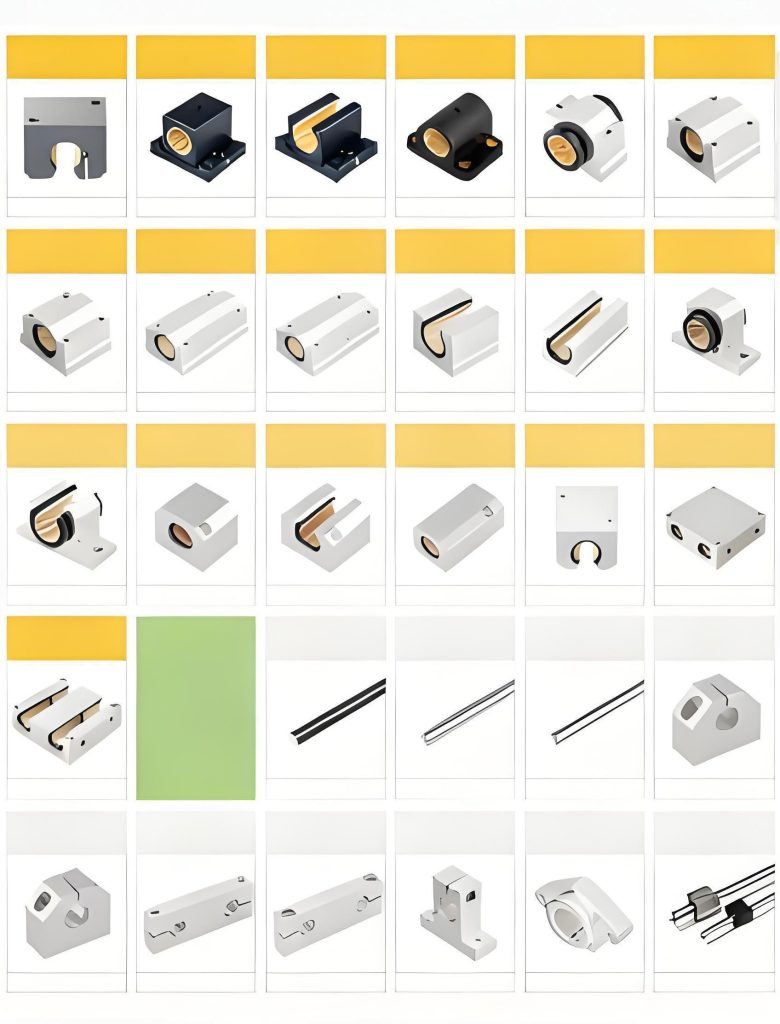

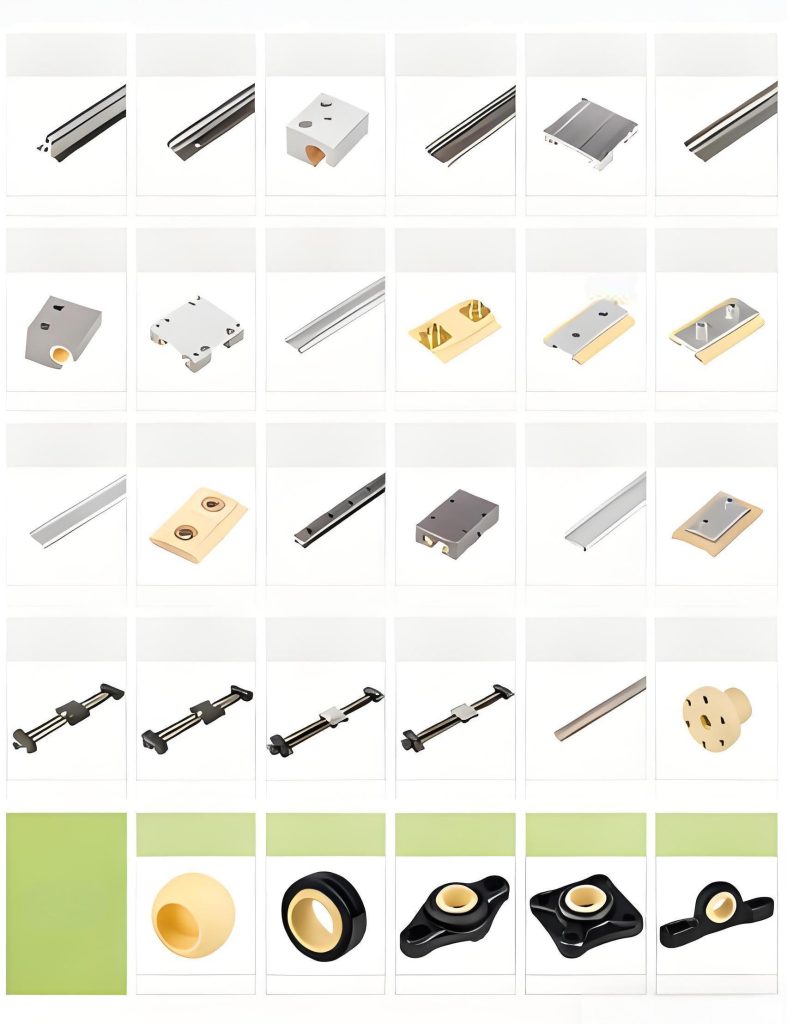

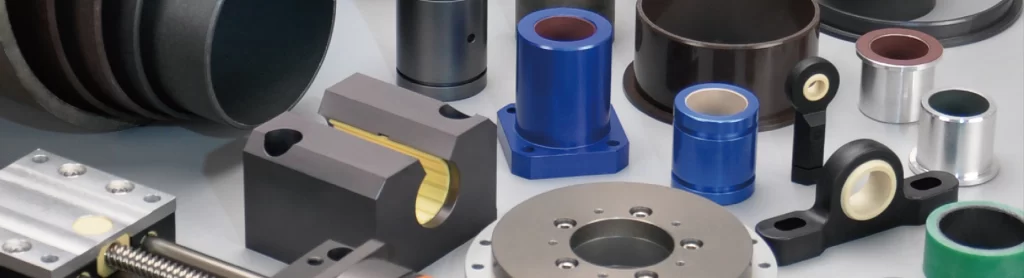

Plastic Bushings by Structure

MYWAY products can be tailored to your specific requirements.

Direct Replacements For

| Brand | Series/Models |

|---|---|

| GGB | EP12, EP15, EP22 |

| SKF | PPMF |

| DAIDYNE | DAIFORCE, DAIHILON DHA |

| CSB | CSB-EPB |

| GLT | COM-KU |

| DE | PDE/COM |

| COB | HPC |

| IGUS | iglide |

| Sankyo Oiless | POB |

Plastic Bushing: A Comprehensive Guide to Engineering Polymer Bearings

Introduction to Plastic Compound Bushings

In the evolving landscape of industrial components, plastic compound bushings have emerged as revolutionary solutions across countless applications. These advanced polymer bearings represent a significant departure from traditional metal bushings, offering unique benefits that make them indispensable in industries ranging from automotive manufacturing to food processing equipment. At their core, plastic composite bushings are sleeve bearings manufactured through the precise combination of high-performance engineering plastics with specialized reinforcing fibers and solid lubricants. This sophisticated material composition results in components that deliver exceptional performance where traditional metal bushings often fall short.

The fundamental structure of these bushings typically involves a polymer matrix – often using materials like POM, PTFE, or nylon – reinforced with fibers for added strength and integrated solid lubricants for reduced friction. This construction enables what industry professionals refer to as maintenance-free operation, as these bushings require no external lubrication throughout their service life. As manufacturing trends continue toward lightweight, corrosion-resistant, and environmentally friendly components, plastic compound bushings have seen rapid adoption, with market analyses projecting steady growth in the POM bushing segment through 2031 as more engineers recognize their advantages over conventional alternatives.

Key Advantages of Plastic Composite Bushings

Lightweight and Corrosion-Resistant

One of the most significant benefits of plastic composite bushings is their exceptional power-to-weight ratio. Weighing significantly less than their metal counterparts, these components contribute to overall equipment weight reduction, leading to energy savings and improved efficiency in moving applications. This characteristic is particularly valuable in industries like automotive manufacturing and aerospace, where every gram reduction translates to enhanced performance. Additionally, unlike metal bushings that are susceptible to rust and corrosion, plastic bushings demonstrate remarkable resistance to a wide range of chemical corrosive agents, including acids, alkalis, and solvents. This inherent corrosion resistance eliminates the need for protective coatings and makes them ideal for applications in harsh environments where exposure to moisture or chemicals is inevitable.

Self-Lubricating and Maintenance-Free

The self-lubricating properties of plastic compound bushings represent perhaps their most valuable advantage in many applications. Through advanced material engineering, solid lubricants are integrated directly into the polymer matrix structure, creating a continuous lubricating film at the bearing surface during operation. This built-in lubrication system eliminates the need for external grease or oil, making these bushings truly maintenance-free solutions. The implications for industry are substantial – reduced maintenance costs, elimination of lubrication schedules, and prevention of contamination in sensitive environments like food processing equipment or medical devices. For engineers designing equipment with hard-to-reach components or sealed systems, this self-lubricating characteristic provides a practical solution to the challenge of providing ongoing lubrication throughout the product lifecycle.

Excellent Wear Resistance and Noise Reduction

Plastic compound bushings are engineered for long-term durability in demanding applications. The incorporation of high-strength fibers and specialized additives within the polymer matrix creates a composite material with outstanding resistance to wear, even under continuous operation. This enhanced wear resistance capability translates directly to extended service life and reduced downtime for component replacement. Additionally, the inherent damping characteristics of polymer materials result in significantly reduced operational noise compared to metal bushings. The quieter operation is not merely an comfort consideration – in many applications, it indicates reduced vibration and smoother mechanical performance, contributing to improved overall system reliability and precision.

Table: Performance Comparison – Plastic Composite Bushings vs. Traditional Bronze Bushings

| Characteristic | Plastic Composite Bushing | Traditional Bronze Bushing |

|---|---|---|

| Weight | Lightweight (approx. 1/7 of bronze) | Heavy |

| Corrosion Resistance | Excellent | Poor (requires protection) |

| Lubrication Requirement | Self-lubricating | Regular lubrication needed |

| Noise Generation | Low | Moderate to High |

| Wear Resistance | Excellent with proper material selection | Good |

| Cost Efficiency | Higher long-term value | Lower initial cost, higher maintenance |

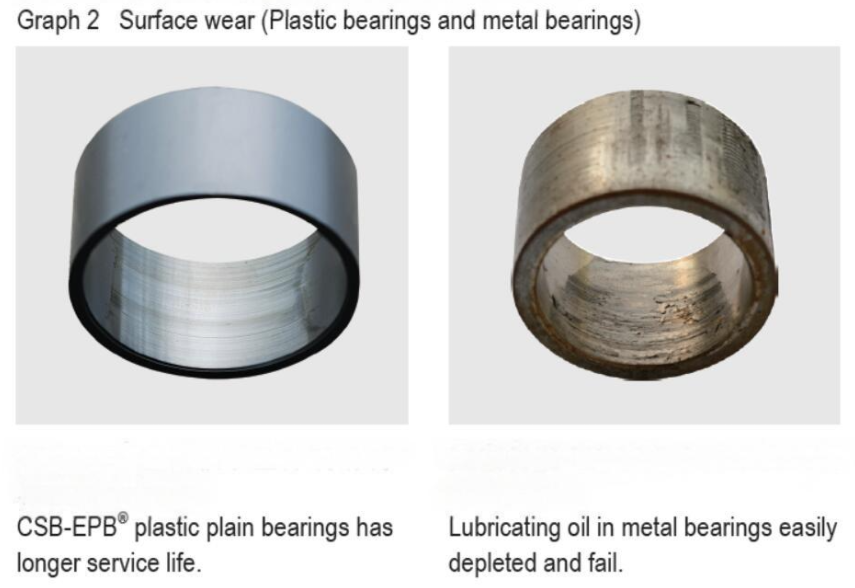

Plastic Bearings vs. Traditional Oil-Impregnated Bearings

Since the lubricating grease is integrated into the overall material of the Plastic bearings, the grease will continuously exude onto the friction surface regardless of the bearing’s operating duration, providing long-term lubrication. In contrast, traditional powder metallurgy oil-impregnated bearings rely on the oil within their micro-pores for self-lubrication during use. Once this oil is depleted or evaporates, bearing wear accelerates rapidly, marking the end of the bearing‘s effective service life.

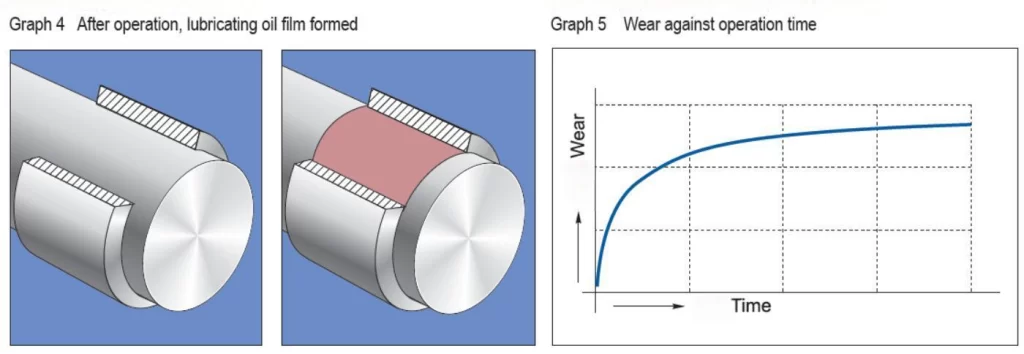

Plastic Bearing Wear

Any self-lubricating bearing will experience minimal wear once it operates under load. The Plastic bearings are no exception. During the initial running-in phase, as minimal wear occurs, lubricating grease exudes and gradually fills the friction surface, transferring to the surface of the matching shaft. Once the working area of the matching shaft is fully covered with lubricating grease, a thin lubricating barrier film is formed. At this point, the initial wear of the bearing nearly concludes, and the wear rate significantly reduces and stabilizes during subsequent extended operation.

Materials and Manufacturing Technologies

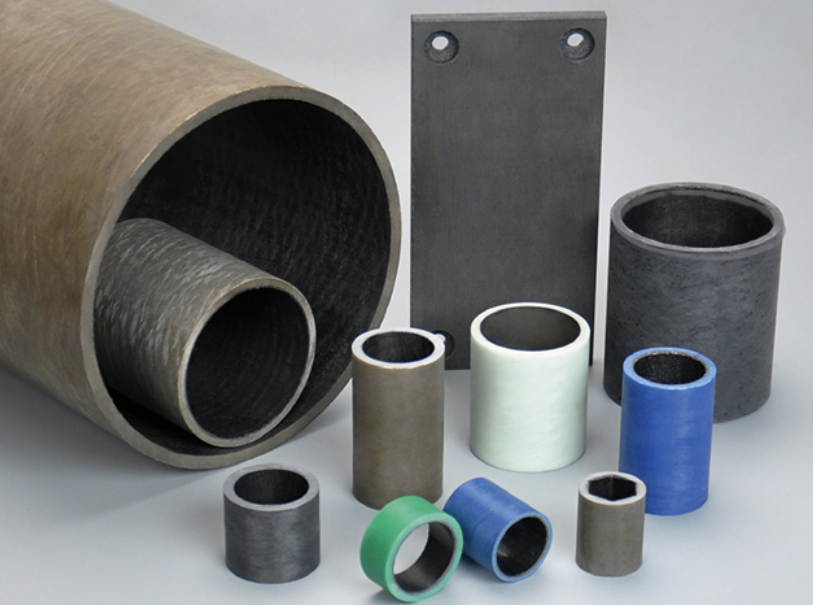

Advanced Polymer Composites

The performance characteristics of plastic compound bushings are directly tied to their sophisticated material compositions. Leading manufacturers have developed specialized formulations like the plastic bushings, which utilizes high-performance engineering plastics as the base material, enhanced through polymer modification technology with the addition of high-strength fibers and special solid lubricants. These composite materials are engineered to meet specific operational challenges – for instance, EPB3M combines shock absorption with wear resistance, while EPB5 offers temperature resistance up to 250°C along with enhanced chemical corrosion resistance. For applications requiring minimal friction, EPB13 provides an exceptionally low friction coefficient, and EPB7 delivers superior wear resistance performance for high-load applications. This material diversity enables engineers to select precisely the right bushing formulation for their specific operational requirements across industries from office automation equipment to underwater applications.

Precision Manufacturing Processes

The production of high-quality plastic composite bushings relies on advanced manufacturing technologies, with injection molding process standing as the predominant method. This manufacturing approach allows for the creation of complex geometries with consistent dimensional accuracy and excellent surface finishes, all while maintaining the cost-efficiencies necessary for large-scale production. For specialized applications, manufacturers may employ filament winding technology, particularly for creating self-lubricating bearings with customized wall thicknesses and directional strength properties. The manufacturing process doesn’t end with forming – precision machining operations are often employed to achieve the tight tolerances required in modern industrial applications, ensuring perfect fit and optimal performance in the final assembly.

Applications Across Industries

Automotive and Transportation Systems

The automotive industry has embraced plastic compound bushings across numerous applications, leveraging their lightweight characteristics to contribute to overall vehicle weight reduction for improved fuel efficiency. In suspension systems, these bushings provide excellent vibration damping properties, enhancing ride comfort while withstanding the constant stress of road irregularities. Engine components benefit from their temperature resistance and self-lubricating properties in locations where lubrication is challenging. Transmission systems utilize specialized polymer bushings for their wear resistance and ability to operate effectively in oil-lubricated environments. As vehicle manufacturers pursue quieter cabins, the noise reduction qualities of plastic composite bushings have become increasingly valuable, making them preferred solutions in seat adjustment mechanisms, steering column assemblies, and various linkage points throughout modern vehicles.

Food Processing and Pharmaceutical Equipment

In industries with stringent hygiene requirements, such as food processing and pharmaceutical manufacturing, plastic compound bushings offer distinct advantages. Many formulations comply with FDA regulations for food contact, making them suitable for use in processing equipment where lubrication contamination must be avoided. Their inherent corrosion resistance stands up to the aggressive cleaning chemicals and high-moisture environments typical in these industries, while their self-lubricating nature eliminates the risk of product contamination from lubricants. Additionally, the non-galvanic corrosion properties of polymer materials prevent the pitting and deterioration that can harbor bacteria in metal components, contributing to improved sanitation and easier maintenance of processing equipment.

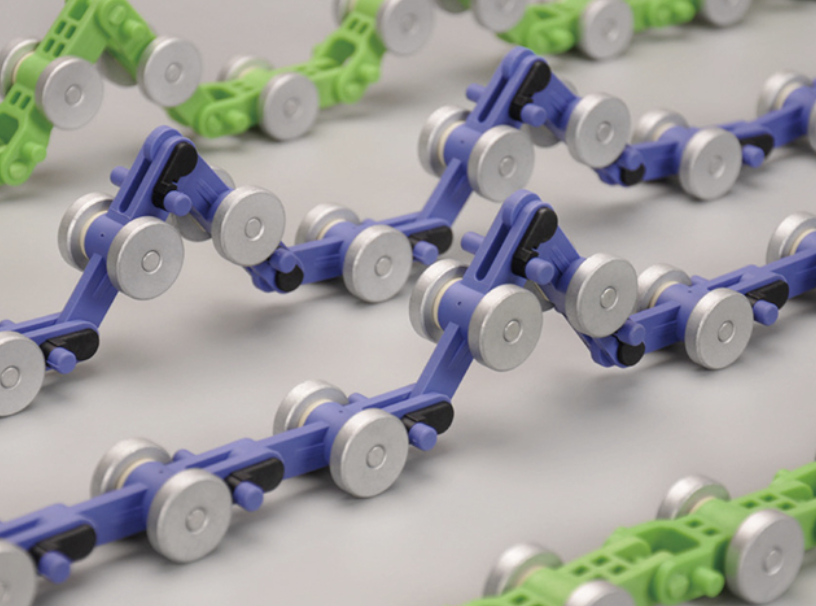

Specialized Industrial Applications

Beyond automotive and food processing, plastic composite bushings deliver value across a diverse range of specialized applications. In textile machinery, they provide smooth, maintenance-free operation while resisting contamination from fibers and dust. Office automation equipment benefits from their quiet operation and precision in countless moving components. Applications requiring underwater operation leverage specially formulated materials that maintain their properties when submerged, while high-temperature environments utilize grades engineered for thermal stability. The chemical industry employs these bushings in pumps, mixers, and valves where resistance to aggressive chemicals is paramount. Across these diverse applications, the common benefits remain: reduced maintenance, corrosion resistance, weight savings, and improved reliability compared to traditional bushing materials.

Design and Installation Considerations

Proper Application Engineering

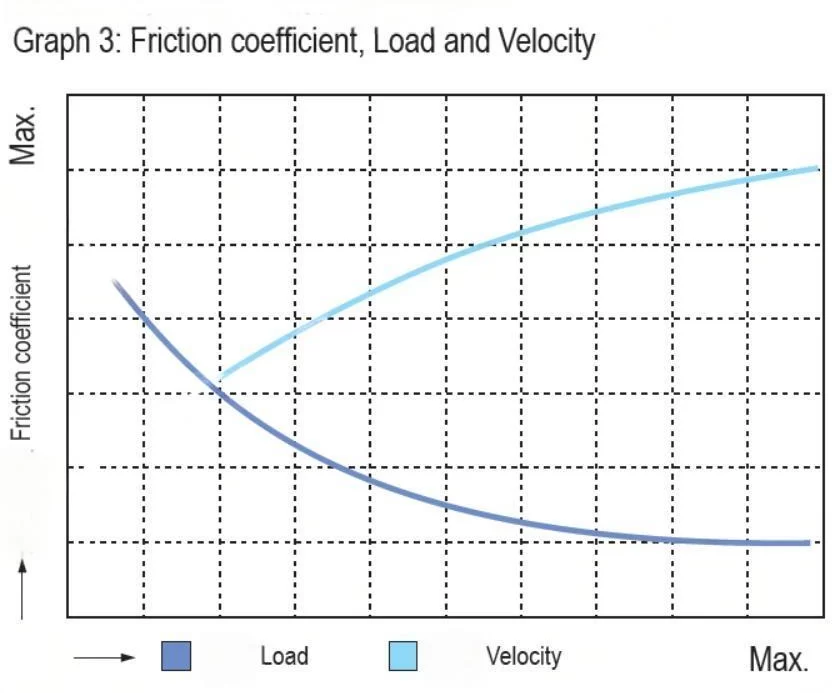

Successfully implementing plastic compound bushings requires careful consideration of several application factors to ensure optimal performance and service life. Engineers must evaluate the operational load parameters, both static and dynamic, to select the appropriate material grade with sufficient pressure capacity. The velocity of movement is another critical factor, as different polymer composites exhibit varying performance characteristics across speed ranges. Temperature operating range must be considered, not just during operation but also during any processing such as E-painting or sterilization that might expose the bushings to extreme conditions. Additionally, environmental factors such as exposure to chemical corrosive agents, moisture, UV radiation, or abrasive contaminants will influence material selection. By carefully analyzing these parameters during the design phase, engineers can select the ideal plastic composite bushing formulation for their specific application, maximizing performance and service life.

Installation Best Practices

Correct installation is crucial for realizing the full performance potential of plastic compound bushings. Unlike metal bushings, these components typically require precise interference fits to ensure optimal performance. The housing bore should be clean and free of sharp edges that might damage the bushing during press-fitting. Using proper installation tools that apply pressure evenly across the bushing face – rather than just on one edge – prevents deformation and ensures proper alignment. For press-fit applications, controlling the installation velocity prevents rapid compression that could potentially stress the polymer material. Additionally, designers should account for the different thermal expansion coefficients of plastic versus metal in applications with significant temperature variations, ensuring that clearance remains appropriate across the entire operating temperature range to prevent either excessive play or binding.

MYWAY Bushings: Your Expert Partner in Plastic Compound Solutions

At MYWAY, we recognize that every application presents unique challenges and requirements. Our comprehensive line of plastic compound bushings represents the culmination of extensive research and development in advanced polymer technology, delivering solutions that outperform traditional materials across a wide range of industrial applications. We specialize in providing customized bushing solutions engineered to meet your specific operational needs, leveraging state-of-the-art manufacturing capabilities and technical expertise.

Our Technical Capabilities

Custom Material Formulations: We engineer composite materials tailored to your specific requirements, whether you need enhanced chemical corrosion resistance, extreme temperature tolerance, or specialized lubrication properties.

Precision Manufacturing: Our advanced injection molding capabilities ensure consistent, high-quality bushings produced to exacting tolerances for reliable performance in your applications.

Application Engineering Support: Our technical team provides comprehensive support from concept through production, helping you select or develop the ideal bushing solution for your specific operational parameters.

The MYWAY Advantage

When you partner with MYWAY for your plastic compound bushing needs, you gain access to more than just components – you acquire a comprehensive solution backed by engineering expertise and commitment to quality. Our products deliver the exceptional wear resistance and maintenance-free operation that modern industries demand, while our responsive customer service ensures you receive the technical support necessary for successful implementation.

Contact MYWAY today to discuss your specific application requirements. Our technical team stands ready to help you select or develop the perfect plastic compound bushing solution to enhance your equipment’s performance, reduce maintenance costs, and improve operational reliability.

MYWAY Plastic Bushing FAQs

1. What are the primary advantages of plastic composite bushings over bronze bushings?

Plastic composite bushings offer several significant advantages over traditional bronze bushings. They are substantially lighter in weight – typically about one-seventh the weight of comparable bronze components – contributing to overall equipment weight reduction. They require no external lubrication, as they are self-lubricating, which eliminates maintenance schedules and prevents contamination in sensitive applications. Plastic bushings demonstrate excellent corrosion resistance to chemicals and moisture that would damage bronze components. They operate more quietly due to the vibration damping characteristics of polymer materials, and they won’t gall or seize to shafts like bronze bushings can under marginal lubrication conditions.

2. What temperature ranges can plastic compound bushings withstand?

The temperature resistance of plastic compound bushings varies depending on the specific material formulation. Standard materials typically perform effectively in ranges from -40°C to 120°C (-40°F to 250°F). Specially engineered formulations like those in the EPB5 grade can withstand continuous operation at temperatures up to 250°C (480°F), while other specialized materials maintain their properties at cryogenic temperatures as low as -200°C (-328°F). It’s important to consult with technical specialists when applications involve extreme temperature conditions to ensure the appropriate material selection.

3. How do self-lubricating plastic bushings work without external lubrication?

Self-lubricating plastic bushings function through sophisticated material engineering that integrates solid lubricants directly into the polymer composite matrix. During operation, a thin, continuous film of these lubricants transfers to the mating shaft surface, creating a low-friction interface between the moving components. This transfer film is constantly renewed from the reservoir of solid lubricants within the bushing material throughout its service life. The most common solid lubricants include PTFE, graphite, and silicone, each offering different performance characteristics suitable for various application requirements.

4. What factors should I consider when selecting a plastic compound bushing?

Selecting the optimal plastic compound bushing requires consideration of several application parameters. Key factors include: the magnitude and type of loading (static, dynamic, or impact); the rotational or oscillatory speed; the operating temperature range; environmental conditions such as exposure to chemicals, moisture, or abrasives; and any regulatory requirements such as FDA compliance for food-related applications. Additionally, consider dimensional constraints and installation method to ensure proper fit and performance. Consulting with a technical expert during the selection process can help identify the most appropriate material and design for your specific application.

5. Are plastic composite bushings cost-effective compared to metal bushings?

While the initial purchase price of plastic composite bushings may be higher than simple metal bushings in some cases, their total cost of ownership is typically significantly lower. The elimination of lubrication systems and associated maintenance labor provides substantial savings over the equipment lifecycle. Additionally, the longer service life and reduced downtime for replacement contribute to improved operational efficiency. The corrosion resistance of plastic bushings eliminates the need for protective coatings and prevents premature failure in challenging environments, further enhancing their cost-effectiveness compared to metal alternatives.