Recent Posts

PTFE Temperature Range: Mastering Performance from Cryogenic Cold to Extreme Heat

If you’ve ever wondered why a PTFE (Teflon) bushing failed unexpectedly in a high-load application, or struggled to select the right material for an extreme temperature environment, you’re not alone. The secret to unlocking PTFE’s full potential—and avoiding costly failures—lies in a deep understanding of its relationship with temperature.

PTFE boasts one of the widest service temperature ranges of any polymer, but its performance is anything but constant across that spectrum. This guide moves beyond basic datasheet numbers to explore how heat and cold fundamentally transform PTFE’s behavior. We’ll provide actionable insights for engineers and procurement specialists to make informed decisions, ensuring reliability and longevity in your most demanding applications.

Table of Contents

1. The PTFE Temperature Spectrum: More Than Just Numbers

At first glance, the numbers are impressive: PTFE is generally considered operational from approximately -250°C to +260°C (-418°F to +500°F). In some forms, such as expanded PTFE tape, the range can extend from -268°C to +280°C. This incredible breadth is why PTFE is a go-to material for everything from cryogenic systems to chemical processing equipment.

However, labeling it as merely “heat resistant” is a significant oversimplification. PTFE undergoes profound molecular changes with temperature. It’s technically a thermoplastic, yet once sintered, it behaves more like a thermoset, resisting re-melting. A critical transition begins surprisingly close to room temperature, around 25°C (78°F), where the phenomenon of “cold flow” or creep becomes a design factor. This means that under constant load, PTFE will slowly and permanently deform, and this deformation accelerates dramatically as temperature rises.

2. Performance Under the Microscope: How Temperature Dictates Behavior

To design effectively, you must understand how key mechanical properties shift. Relying on room-temperature data for a high-temperature application is a recipe for failure.

The table below summarizes the dramatic impact of temperature:

| Property | Low-Temperature Behavior (e.g., -100°C) | High-Temperature Behavior (e.g., +200°C) | Critical Design Implication |

|---|---|---|---|

| Mechanical Strength | Increased stiffness and hardness. | Severe reduction in tensile and compressive strength. | Load-bearing capacity plummets. A part strong at room temp may deform or fail under load when hot. |

| Creep Resistance | Good resistance to deformation under load. | Very poor. Pronounced “cold flow.” | Not suitable for sustained high static loads at elevated temperatures without support. |

| Elongation & Toughness | Becomes brittle; impact strength decreases. | More ductile, but material is vastly weaker. | Risk of fracture under shock load at cryogenic temps. |

| Thermal Expansion | Material contracts. | Extremely high expansion (≈10x that of steel). | Must design clearances to avoid binding when hot or excessive play when cold. |

| Coefficient of Friction | Remains excellently low, though may slightly increase. | Remains excellently low, its most stable property. | The premier self-lubricating performance is maintained across the range. |

The High-Temperature Challenge: The most critical takeaway is the drastic loss of strength and creep resistance. For instance, studies show virgin PTFE can lose about 75% of its room-temperature tensile strength at 260°C. Furthermore, as temperature increases, the maximum allowable PV value (Pressure x Velocity) for a bushing decreases. Exceeding this temperature-dependent limit leads to rapid wear and failure.

The Low-Temperature Reality: While PTFE doesn’t become unstable at cryogenic temperatures, it turns brittle. Applications require careful design to avoid shock loads that could cause cracking.

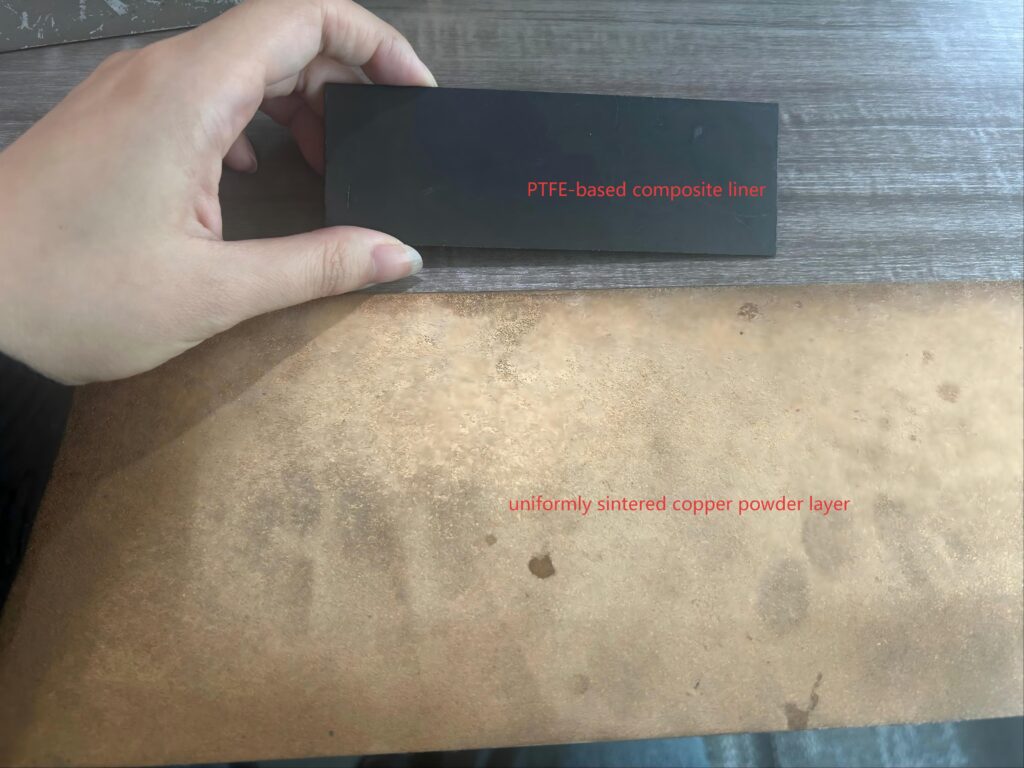

3. The Engineering Solution: Why Composite Bushings Are Essential

Pure PTFE’s thermal limitations make it unsuitable for high-load, high-temperature dynamic applications on its own. This is where engineered composite bushings, like steel-backed PTFE bushings, become indispensable. They are not just a product; they are a system designed to mitigate PTFE’s weaknesses.

Controlling Thermal Expansion: The steel backing provides dimensional stability. While the PTFE layer expands significantly, the metal housing constrains it, maintaining critical running clearances and preventing seizure.

Enhancing Load Capacity: The steel or bronze substrate carries the structural load, while the thin, filled PTFE layer provides the self-lubricating sliding surface. This allows the bushing to withstand pressures pure PTFE could never handle.

Managing Frictional Heat: PTFE is a thermal insulator. In a composite bushing, the bronze sintered layer or metal backing acts as a heat sink, drawing frictional heat away from the critical PTFE interface, helping to keep it within a safer operating window. Research on fabric-lined PTFE bushings has demonstrated stable performance in tests at least up to 163°C (325°F), highlighting the effectiveness of composite structures.

4. Advanced Materials: Pushing the Boundaries

The quest for better performance drives continuous innovation. Beyond standard filled PTFE (with bronze, carbon, or glass), advanced composites are emerging:

PTFE/FEP Blends: Alloys with Fluorinated Ethylene Propylene (FEP) can enhance processability and certain performance aspects in specific conditions.

Nanocomposites: Cutting-edge research shows that additives like Boron Nitride Nanobarbs (BNNBs) can significantly extend the thermal lifetime of PTFE, potentially by an order of magnitude, by improving thermal stability and degradation resistance.

5. Introducing MYWAY: Your Partner for High-Performance Bushing Solutions

At MYWAY, we don’t just sell bushings; we solve engineering challenges. Understanding the complex interplay between material, temperature, and application is at the core of what we do.

Our MYWAY Advantage:

Precision-Engineered Composites: We specialize in manufacturing high-quality steel-backed, self-lubricating composite bushings. Our products are meticulously engineered to balance the exceptional low-friction of PTFE with the strength and thermal stability of metal, ensuring reliable performance across the advertised temperature range.

Application-Specific Expertise: Is your application in a high-temperature hydraulic system, a cryogenic valve, or a heavily loaded industrial pivot? Our technical team helps you navigate PV limits, thermal expansion considerations, and filler material selection (bronze for conductivity, carbon for wear resistance, etc.) to specify the optimal bushing.

Full-Scale Manufacturing & Quality: As a leading manufacturer, we control the process from material selection to sintering and final precision pressing. Our commitment to quality ensures every bushing meets stringent standards for dimensional accuracy and performance consistency, suitable for demanding sectors from automotive to aerospace where specifications like maximum service temperatures of 260°C are mandated.

Ready to Spec With Confidence?

Stop compromising between temperature resistance, load capacity, and longevity. Let MYWAY’s expertise guide you to the optimal bushing solution.

Contact us today for a technical consultation or to request a quote. Provide your application details, including operating temperature range, load, and motion type, and we’ll recommend the engineered bushing that will deliver durability and reduce your total cost of ownership.

6. FAQ: Your PTFE Bushing Temperature Questions Answered

Q1: What is the maximum continuous service temperature for a standard PTFE bushing?

For pure PTFE, the recommended maximum continuous service temperature is typically 260°C (500°F). For composite metal-backed PTFE bushings, the limit is often defined by the binder or the overall system design, but high-quality engineered composites can be designed to operate reliably at this upper range. Always consult the manufacturer’s specific datasheet for the exact grade.

Q2: Can PTFE bushings be used in cryogenic applications?

Yes. PTFE remains mechanically stable at extremely low temperatures, down to -250°C and below. The key consideration is its increased brittleness; applications must be designed to minimize shock loading and stress concentrations.

Q3: Why did my PTFE bushing fail prematurely in a “high-temperature” application?

Failure at elevated temperature is rarely due to melting. The most common causes are:

Exceeding the temperature-adjusted PV limit: The combined pressure and speed generated too much frictional heat, weakening the PTFE.

Creep (Cold Flow): Sustained load at high temperature caused permanent deformation.

Thermal Expansion Mismanagement: Lack of proper clearance led to binding and excessive wear.

This is precisely why choosing a properly designed composite bushing from an expert manufacturer like MYWAY is critical.

Q4: What’s the difference between “virgin” and “filled” PTFE in bushings?

Virgin PTFE offers the best chemical resistance and lowest friction. Filled PTFE (with bronze, carbon, graphite, etc.) is used in bushings to dramatically improve wear resistance, reduce creep, and enhance thermal conductivity, making it suitable for heavy-duty, high-load applications at the expense of some chemical purity.

Q5: How do I select the right bushing for a wide temperature swing application?

Focus on the composite solution. A steel-backed PTFE bushing is ideal because the metal backing controls the dimensional change. You must calculate running clearances based on the differential expansion between the steel housing/bushing and the shaft (both metal) over the entire temperature cycle, which our engineering team can assist with.

100000+ Types of Bushings – Contact Us for Details