High performance | Long term durability | Environmental adaptability

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

Home » Soild Lubricating Bushing

Graphite Bushing / Soild Lubricating Bushing

What is Graphite Bushing / Soild Lubricating Bushing?

Soild Lubricating Bushing consist of a metal matrix with precisely designed cavities that are filled with oil-impregnated graphite or molybdenum disulfide solid lubricants. During operation under oil-free conditions, frictional heat promotes the transfer of these solid lubricants onto the contact surface, effectively reducing the coefficient of friction.

Our products meet international advanced performance standards. Manufactured using high-precision CNC machinery and strict ISO/TS 16949 quality control protocols, we ensure consistent, high-quality bushings for all applications.

To accommodate diverse operating conditions and customized requirements, we offer an extensive selection of Soild Lubricating Bushing models. We also provide tailored solutions and develop new products based on specific customer needs.

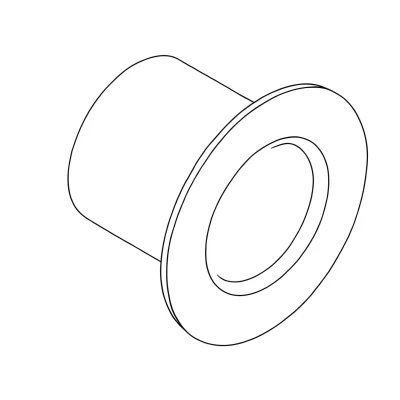

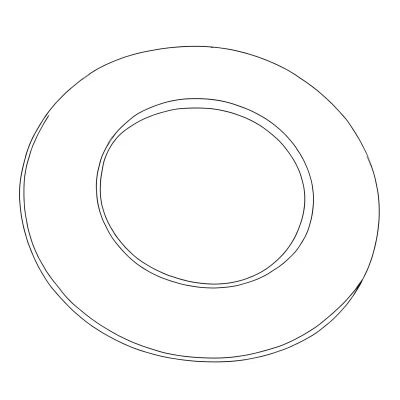

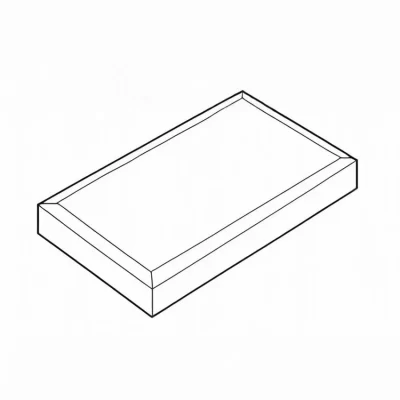

Graphite Bushing / Soild Lubricating Bushings by Structure

Graphite Bushing / Soild Lubricating Bushings by Material

Graphite Bushing / Soild Lubricating Bushings by Type

Which Specification Do You Need?

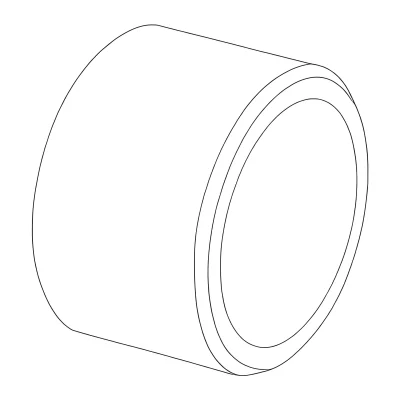

Plain Bushing

| Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. |

| 0808 | 8×12×8 | 1312 | 13×19×12 | 1619 | 16×22×19 | 2040 | 20×28×40 | 3525 | 35×45×25 | 4545 | 45×55×45 |

| 0810 | 8×12×10 | 1315 | 13×19×15 | 1620 | 16×22×20 | 2050 | 20×28×50 | 3530 | 35×45×30 | 4550 | 45×55×50 |

| 0812 | 8×12×12 | 1320 | 13×19×20 | 1625 | 16×22×25 | 2512 | 25×33×12 | 3535 | 35×45×35 | 4560 | 45×55×60 |

| 0815 | 8×12×15 | 1410 | 14×20×10 | 1630 | 16×22×30 | 2516 | 25×33×16 | 3540 | 35×45×40 | 4570 | 45×55×70 |

| 1008 | 10×14×8 | 1412 | 14×20×12 | 1635 | 16×22×35 | 2520 | 25×33×20 | 3545 | 35×45×45 | 5030 | 50×60×30 |

| 1010 | 10×14×10 | 1415 | 14×20×15 | 1640 | 16×22×40 | 2525 | 25×33×25 | 3550 | 35×45×50 | 5035 | 50×60×35 |

| 1012 | 10×14×12 | 1420 | 14×20×20 | 1812 | 18×24×12 | 2530 | 25×33×30 | 3560 | 35×45×60 | 5040 | 50×60×40 |

| 1015 | 10×14×15 | 1425 | 14×20×25 | 1815 | 18×24×15 | 2535 | 25×33×35 | 4020 | 40×50×20 | 5050 | 50×60×50 |

| 1020 | 10×14×20 | 1430 | 14×20×30 | 1820 | 18×24×20 | 2540 | 25×33×40 | 4025 | 40×50×25 | 5060 | 50×60×60 |

| 1208 | 12×18×8 | 1510 | 15×21×10 | 1825 | 18×24×25 | 2550 | 25×33×50 | 4030 | 40×50×30 | 5070 | 50×60×70 |

| 1210 | 12×18×10 | 1512 | 15×21×12 | 1830 | 18×24×30 | 3015 | 30×38×15 | 4035 | 40×50×35 | 5535 | 55×70×35 |

| 1212 | 12×18×12 | 1515 | 15×21×15 | 2010 | 20×28×10 | 3020 | 30×38×20 | 4040 | 40×50×40 | 5540 | 55×70×40 |

| 1215 | 12×18×15 | 1520 | 15×21×20 | 2012 | 20×28×12 | 3025 | 30×38×25 | 4050 | 40×50×50 | 5545 | 55×70×45 |

| 1216 | 12×18×16 | 1525 | 15×21×25 | 2016 | 20×28×16 | 3030 | 30×38×30 | 4060 | 40×50×60 | 5550 | 55×70×50 |

| 1219 | 12×18×19 | 1530 | 15×21×30 | 2019 | 20×28×19 | 3035 | 30×38×35 | 4070 | 40×50×70 | 5560 | 55×70×60 |

| 1220 | 12×18×20 | 1610 | 16×22×10 | 2020 | 20×28×20 | 3040 | 30×38×40 | 4080 | 40×50×80 | 5570 | 55×70×70 |

| 1225 | 12×18×25 | 1612 | 16×22×12 | 2025 | 20×28×25 | 3050 | 30×38×50 | 4530 | 45×55×30 | 6030 | 60×75×30 |

| 1230 | 12×18×30 | 1615 | 16×22×15 | 2030 | 20×28×30 | 3060 | 30×38×60 | 4535 | 45×55×35 | 6035 | 60×75×35 |

| 1310 | 13×19×10 | 1616 | 16×22×16 | 2035 | 20×28×35 | 3520 | 35×45×20 | 4540 | 45×55×40 | …… | …… |

MYWAY products can be tailored to your specific requirements.

Direct Replacements For

| Brand | Series/Models |

|---|---|

| GGB | DB |

| SKF | PBM |

| DAIDYNE | DAISLIDE |

| ISB | JDB |

| CSB | CSB-600, CSB-650 |

| GLT | LUB-MET, BRO-MAS |

| DE | DE600, BWG |

| COB | M08 |

| Sankyo Oiless | SOB, SESB, SOVM, TSOEG, SOSG, SOST |

Applications of Graphite Bushing / Soild Lubricating Bushing

Graphite Bushing / Soild Lubricating Bushing Material

The combination of high-strength bronze alloys and self-lubricating graphite ensures long-lasting, maintenance-free performance.

Materials & Structure:

We use a variety of high-performance bronze alloys tailored to different operating environments:

- Features: Offers excellent mechanical strength and wear resistance, suitable for high-impact loads and heavy friction conditions.

- Applications: Mining equipment, heavy machinery.

- Features: Known for its exceptional corrosion resistance and good casting properties, ideal for humid and marine environments.

- Applications: Marine engineering, shipbuilding.

- Features: Offers high corrosion resistance and strength, perfect for high-load, high-speed applications in high-temperature or acidic environments.

- Applications: Oil drilling equipment, metallurgical machinery.

- Features: Excellent anti-friction and self-lubricating properties, making it ideal for high-temperature, heavy-load applications.

- Applications: Power generation equipment, steel rolling mills, engine components.

Material Structure:

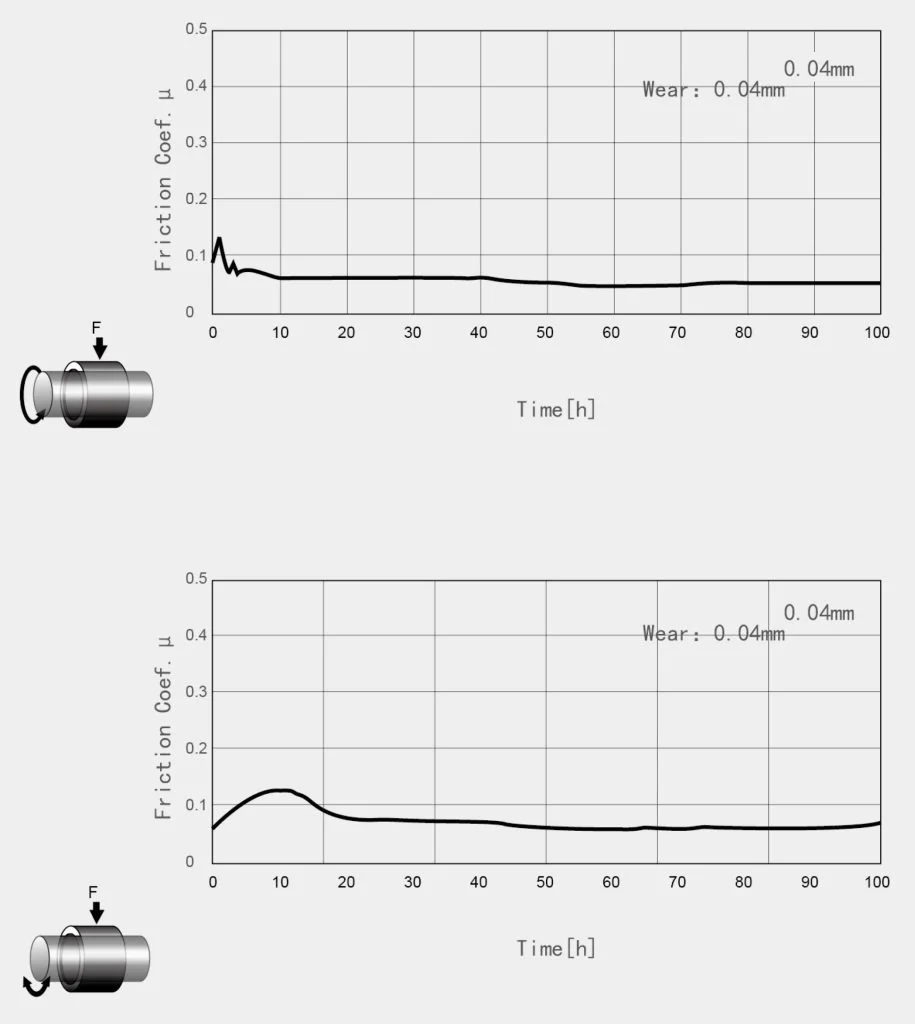

Rotation Test

<Test Condition>

Bearing Size:74x60x50

Mating Shaft:45# HRC42-52

Load:24.5N/mm²

Velocity:0.017m/s

Time: 100h

Temperature:20~25C

Lubrication: Dry

Oscillating Test

<Test Condition>

Bearing Size:50x40x30

Mating Shaft: 45# HRC42-52

Load: 24.5N/mm²

Velocity: 0.017m/s

Angle: 士45Time:100h

Temperature:20~25°C

Lubrication: Dry,

Technical Specifications:

- Operating Temperature: -100°C to 300°C

- Max Load Capacity: Up to 250 N/mm²

- Friction Coefficient: 0.04-0.20 (depending on operating conditions)

- Thermal Expansion Coefficient: 16.5×10⁻⁶/K (suitable for fluctuating temperatures)

- Service Life: 2-5 times longer than standard lubricated bearings.

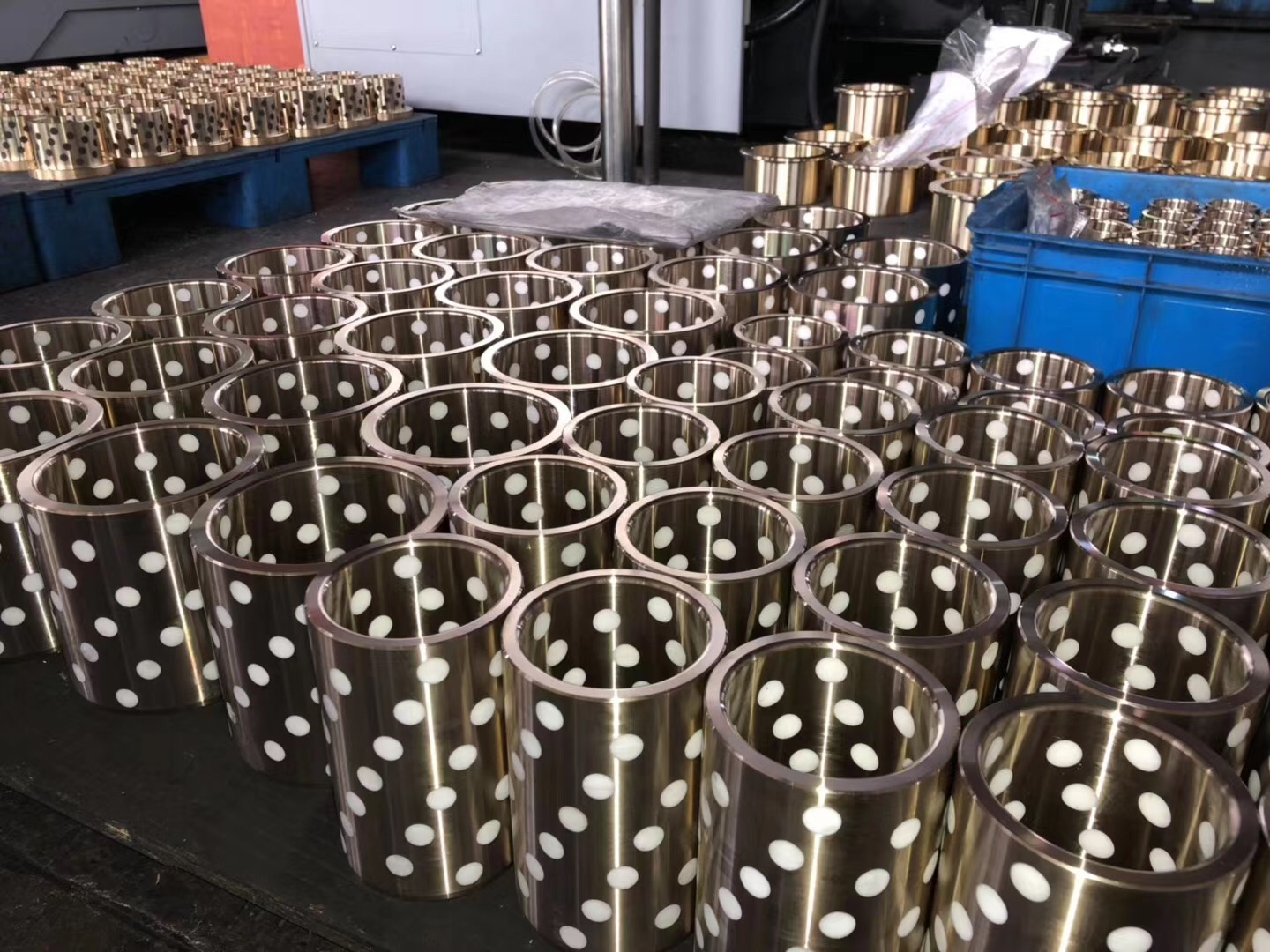

MYWAY Graphite Bushing / Solid Lubricating Bushings: Maintenance-Free Performance with Embedded Graphite Technology

MYWAY Solid Lubricating Bushings are engineered for applications where reliability and minimal maintenance are critical. Designed with integrated solid lubricants, these bushings deliver continuous lubrication without the need for external greasing systems, making them ideal for harsh or inaccessible environments.

Key Performance Benefits:

Maintenance Elimination: Operate indefinitely without regreasing, significantly reducing service interruptions and total cost of ownership.

Enhanced Wear Life: The combination of a durable metal base and solid lubricant offers exceptional resistance to abrasion, even in dirty or dusty conditions.

Corrosion & Chemical Resistance: Graphite-embedded bushings perform steadily in wet, acidic, or alkaline settings where conventional oils break down.

High Load Support: Robust bronze or high-strength brass substrates provide strong mechanical backing for heavy-load and high-pressure applications.

Broad Temperature Suitability: Function effectively across a wide temperature range, including conditions where liquid lubricants degrade or evaporate.

Common Industry Uses:

MYWAY self-lubricating graphite bushings are widely used in:

- Construction Machinery: Excavators, loaders, bulldozers, and other heavy equipment joints and bearing positions, handling high-impact and heavy load conditions.

- Agricultural Machinery: Tractors, combine harvesters, and other farm equipment exposed to outdoor conditions and dust, ensuring long-term lubrication protection.

- Mining Equipment: Conveyor belts, crushers, and other mining machinery benefit from low-speed, high-load capabilities in abrasive environments.

- Metallurgical Equipment: Rolling mills, industrial furnaces, and steel-making machines operating under high temperatures and pressures.

- Power Generation: Bearings in generators, wind turbines, and other rotating equipment requiring long-term stability.

- Marine & Offshore Engineering: Suitable for operation in marine or high-humidity, corrosive environments.

Why Choose Our Graphite-Embedded Bronze Bushings?

Custom Solutions: We offer a variety of sizes, shapes, and material combinations to ensure a perfect fit for your equipment and specific operating conditions.

Quality Assurance: Each product undergoes rigorous quality control testing to ensure optimal performance and durability in the toughest industrial applications.

Industry Expertise: With years of experience serving global industries, we understand the unique requirements of industrial machinery and provide reliable solutions that reduce maintenance costs and downtime.

MYWAY Graphite Bushing / Solid Lubricating Bushing FAQs

1. What are the precautions for using embedded solid-lubricated bushings?

Standard specifications are recommended for design applications. For non-standard requirements, please consult our technical team.

Clean both inner and outer surfaces thoroughly before assembly to ensure complete removal of impurities and foreign particles.

Applying lubricating grease to the friction surface prior to assembly can shorten the run-in period, improve operational smoothness, and extend service life.

During assembly, press-fit the bushing gently into place. Avoid violent impact or hammering, which may cause deformation and reduce performance.

For high-load conditions or reciprocating motions, secure the bushing to the housing hole using set screws.

A black or gray-black lubricating film may form on the shaft surface during operation. Do not remove—this is a normal protective layer.

For optimal performance, shafts should be made of materials with higher hardness than the bushing.

2. Can graphite be used in motor bushings?

Yes. Graphite-embedded bushings are well-suited for various electric motor applications. Their self-lubricating nature ensures smooth operation without oil contamination or maintenance, especially in high-temperature or sealed motor designs where traditional lubrication is impractical.

3. How is graphite applied to a bushing?

While powdered graphite can be used as a temporary supplement, the most effective method is through embedded graphite plugs. At MYWAY, graphite is inserted into precisely machined cavities in the bushing wall during manufacturing. This built-in reservoir steadily supplies lubricant throughout the bushing’s service life, ensuring consistent performance without manual re-lubrication.