Home » Special Shaped Bushing

MYWAY Special Shaped Bushing Product List

What is Special Shaped Bushing?

A special shaped bushing is a precision-engineered, non-cylindrical sleeve bearing designed to provide support, reduce friction, and guide motion in applications where standard geometry is insufficient. Unlike a plain bushing, it incorporates specific functional features—such as integral flanges for axial load management, a split design for easy maintenance, custom contours for unique housings, or pre-machined start holes for tool guidance. These purpose-driven shapes address complex requirements involving combined loads, restricted assembly space, unconventional motion paths, or the need for integrated alignment in tooling. Characterized by its tailored geometry and often constructed from advanced materials like self-lubricating composites or high-hardness tungsten carbide, it transforms from a simple wear part into a critical system component. Its custom design ensures optimal performance, reliability, and service life in demanding applications across metal stamping, precision automation, heavy machinery, and specialized industrial equipment.

A Complete Guide to Special Shaped Bushings for Demanding Applications

Introduction: When Standard Bushings Just Won’t Do

In the world of precision engineering and heavy-duty machinery, the humble bushing is a cornerstone component. But what happens when your application defies convention? When a standard cylindrical sleeve simply can’t meet the geometric, spatial, or performance demands of your design? This is where the specialized world of Special Shaped Bushings comes into play.

Far from being a mere curiosity, special shaped bushings are critical engineering solutions for applications involving non-linear motion, extreme loads, complex assembly constraints, or unique environmental challenges. They are the tailored answer to problems that off-the-shelf, circular bushings cannot solve. This guide delves deep into what they are, where they are essential, and how choosing a specialist manufacturer like MYWAY Bushings can unlock new levels of performance and reliability for your most challenging projects.

What Exactly is a Special Shaped Bushing?

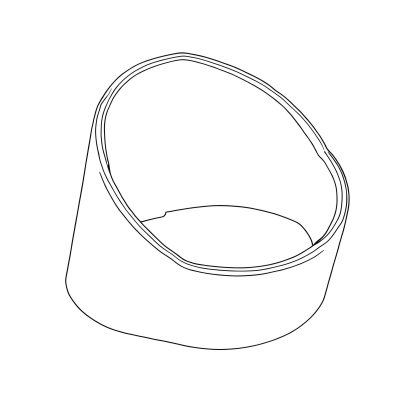

A Special Shaped Bushing is any bearing liner or sleeve whose geometry deviates from a simple, straight-walled cylinder. While a standard bushing is defined by its uniform inner diameter (ID) and outer diameter (OD), a special shaped bushing incorporates unique features into its form. These features are not for aesthetics; they are engineered with a precise functional purpose.

The “special shape” can manifest in several ways:

Non-Circular Profiles: Oval, square, rectangular, or polygonal bores or exteriors.

Integrated Flanges or Collars: Radial protrusions for axial location, load bearing, or simplified mounting.

Tapered Walls: Conical IDs or ODs for specific fit or alignment requirements.

Complex Contours: Custom external or internal geometries that match a housing or shaft profile.

Start Holes or Pre-Drilled Pilot Features: As mentioned in your initial search, these are bushings with pre-formed holes to guide punches or tools, a common need in stamping and piercing dies.

The core principle remains the same as any bushing: to provide a wear-resistant, low-friction interface between moving parts. However, the special shape allows it to do so in situations where load direction, assembly sequence, space limitations, or motion path are unconventional.

Key Types and Applications of Special Shaped Bushings

Special shaped bushings are designed to meet specific mechanical challenges. Here are some of the most critical types and where they prove indispensable.

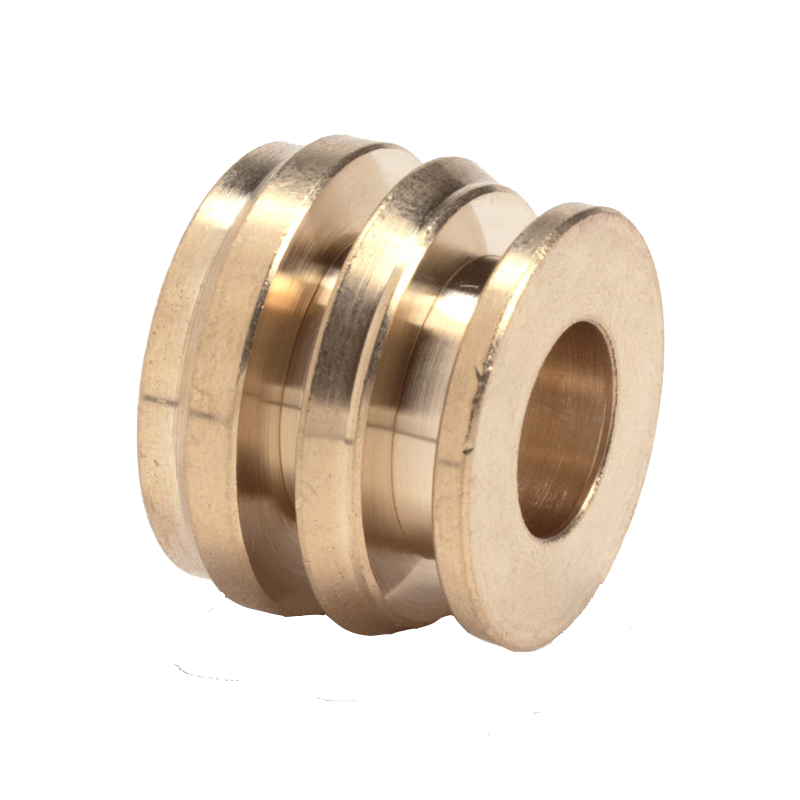

1. Flanged Bushings

Perhaps the most common “special shape,” a flange is a radial collar integrated into the bushing.

Function: The flange provides a built-in shoulder to handle thrust (axial) loads and prevents the bushing from being pushed through its housing during operation. It also simplifies installation and positioning.

Applications: Gearbox assemblies, pulley systems, conveyor rollers, and anywhere a component needs to be precisely located axially while rotating.

2. Split Bushings (Clench or Two-Piece Bushings)

These are bushings that are manufactured in two halves.

Function: They allow for installation and replacement without the need to disassemble entire shafts or surrounding machinery. This is a massive advantage for maintenance in large, complex systems.

Applications: Large crankshafts in engines, marine propeller shafts, paper mill dryer rolls, and critical infrastructure where downtime must be minimized. As noted in industry resources, split designs are crucial for “quick replacement in dryer sections or marine propeller shafts.”

3. Thrust Washers

These are specialized, disc-shaped bushings designed exclusively to manage axial loads between rotating surfaces.

Function: To provide a smooth, low-friction surface for components under high axial pressure, preventing metal-on-metal wear.

Applications: Between gears in transmissions, in clutch assemblies, on rotating tables in machining centers, and within pump housings.

4. Slide Plates and Strips

These transform the bushing concept from a sleeve into a flat or curved plate.

Function: To facilitate low-friction linear motion over large surface areas or along custom paths.

Applications: The guideways of CNC machines, heavy industrial slide gates, injection molding machine platens, and elevator guide systems. Materials like PTFE-based composites are often used here for their exceptional dry-running capabilities.

5. Pierce & Guide Bushings with Start Holes

A critical subtype in tool and die engineering.

Function: These bushings have precisely machined starter holes or internal features that guide cutting punches, pilots, or rods. They ensure perfect alignment, reduce deflection, and dramatically extend the life of perishable tooling components.

Applications: Progressive stamping dies, precision punching machines, and custom fabrication equipment where consistent, accurate hole piercing is required.

The Material Science Behind High-Performance Special Bushings

The shape solves the geometric challenge, but the material determines performance and longevity. Modern special bushings are marvels of material engineering.

Metal-Polymer Composites: A standout technology involves a multi-layer structure. A steel backing provides immense load-bearing strength and structural integrity. This is bonded to a sintered bronze interlayer, which acts as a porous reservoir and excellent heat conductor. The top layer is a PTFE or advanced polymer blend (like POM) offering an extremely low coefficient of friction. This creates a bushing that is self-lubricating, maintenance-free, and capable of handling high loads in dry or poorly lubricated conditions.

Solid Bronze & Bronze Alloys: For extreme load and high-temperature environments, solid or bimetal bronze bushings (like aluminum bronze or tin bronze) are preferred. They can be embedded with solid lubricant plugs (graphite, MoS₂) that act as built-in lubrication reservoirs, perfect for applications like mining crushers or high-temperature ovens where traditional grease would fail.

Specialty Polymers: Materials like Acetal (POM) and reinforced PTFE are chosen for their inherent lubricity, corrosion resistance, and suitability for clean environments like food processing or pharmaceuticals.

The MYWAY Advantage: Engineering Your Special Bushing Solution

At MYWAY Bushings, we understand that a special shaped bushing is not just a product—it’s a critical component of your system’s success. We move beyond simple manufacturing to become your engineering partner. Here’s what sets us apart:

Precision from Blueprint to Part: We specialize in interpreting complex drawings and delivering components with tolerances that meet the most stringent demands, ensuring perfect fit and function in your assembly.

Advanced Material Expertise: Whether your application calls for a high-strength metal-polymer composite for a flanged split bushing, a graphite-embedded bronze for a thrust washer, or a specialty polymer for a custom slide plate, we guide you to the optimal material choice.

Full-Service Custom Manufacturing: From CNC machining and grinding to wire EDM and profile grinding (PG), we control the entire process in-house. This guarantees quality, confidentiality, and faster lead times for your unique geometries.

Focus on Durability & Performance: Our components are engineered to reduce your total cost of ownership. By extending service life, enabling maintenance-free operation, and preventing unplanned downtime, a MYWAY bushing is an investment in reliability.

Ready to Solve Your Unique Engineering Challenge?

If your project is being limited by the constraints of a standard bearing solution, it’s time to explore the possibilities with a custom special shaped bushing. At MYWAY Bushings, we combine expert design consultation with precision manufacturing to deliver the exact component your innovation requires.

Contact us today for a consultation.

Send your drawings and specifications to our engineering team, and let us demonstrate how a tailor-made MYWAY bushing can enhance performance, improve reliability, and streamline your assembly.

MYWAY Bushings – Your Partner for Precision, Beyond the Standard.

Frequently Asked Questions (FAQ)

Q1: When should I consider a special shaped bushing over a standard one?

Consider a special shape when you have: 1) Axial loads that need constraint (use a flange), 2) Space or assembly restrictions that prevent sliding a sleeve over a shaft (use a split design), 3) A need for guided linear motion (use a slide plate), or 4) A non-circular shaft or housing interface.

Q2: Are special shaped bushings always custom-made?

While some flanged or split bushings come in standard sizes, the vast majority are custom-engineered to solve a specific problem in a specific machine. True “special shapes” are inherently tailored.

Q3: Can special bushings be self-lubricating?

Absolutely. In fact, this is a major trend. Technologies like steel-backed PTFE-lined composites or bronze with solid lubricant plugs are perfectly suited for creating maintenance-free special shaped bushings that perform in harsh, dry, or inaccessible environments.

Q4: What information do I need to provide for a quote on a custom bushing?

To get an accurate and fast quote, provide: Engineering drawings (CAD files preferred), material specifications or performance requirements (load, speed, temperature, environment), quantity, and any applicable industry standards.

Q5: Why choose MYWAY over a general-purpose machine shop?

Special bushings require more than just machining skill; they require a deep understanding of tribology (the science of friction), material interactions, and application engineering. MYWAY specializes in this niche, offering not just a part, but a engineered bearing solution that ensures your machine runs smoother and lasts longer.