Home » Thrust Washers

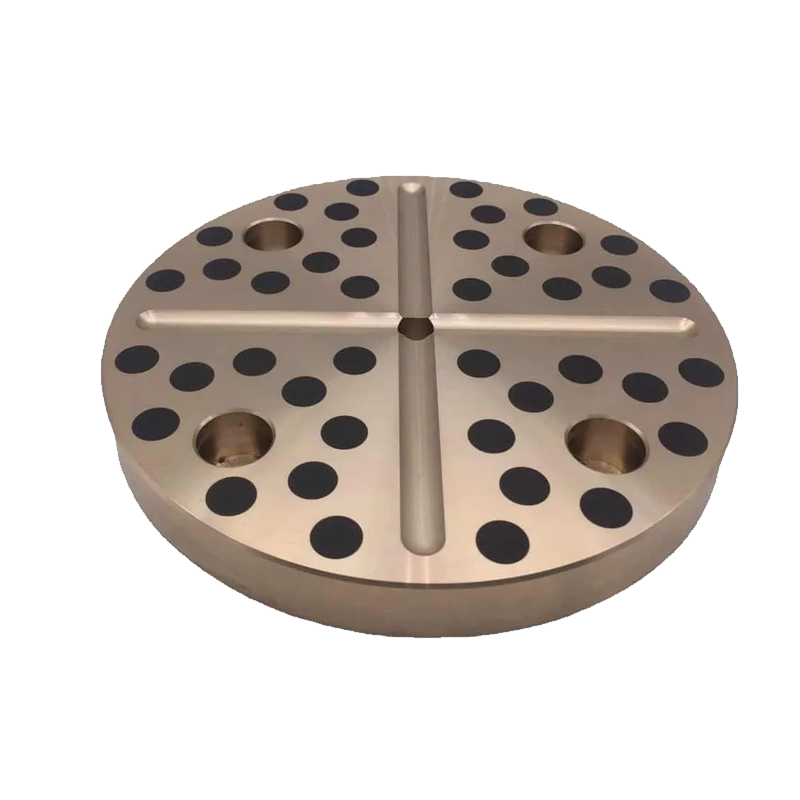

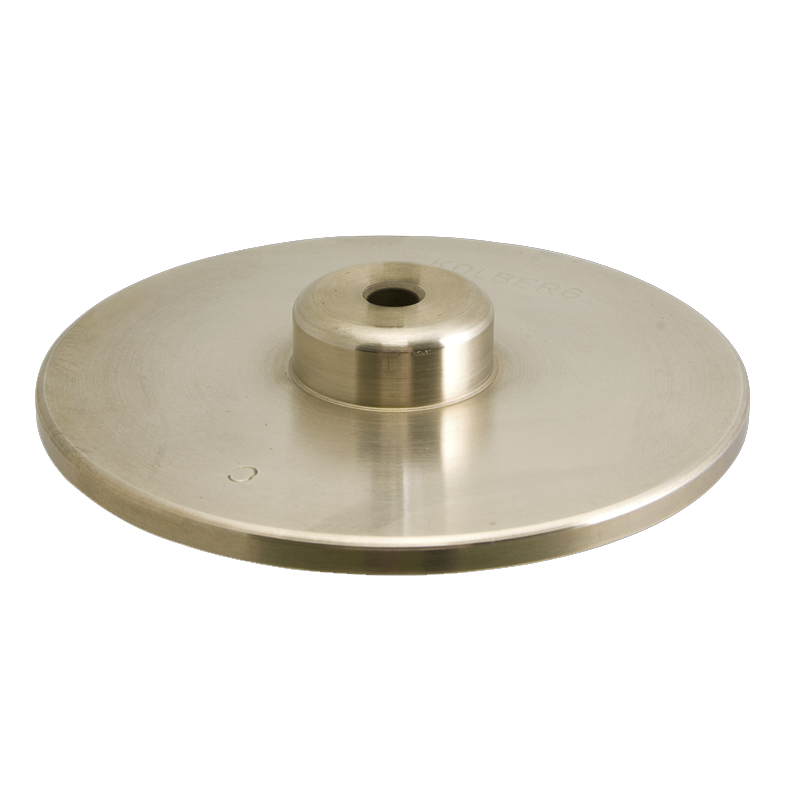

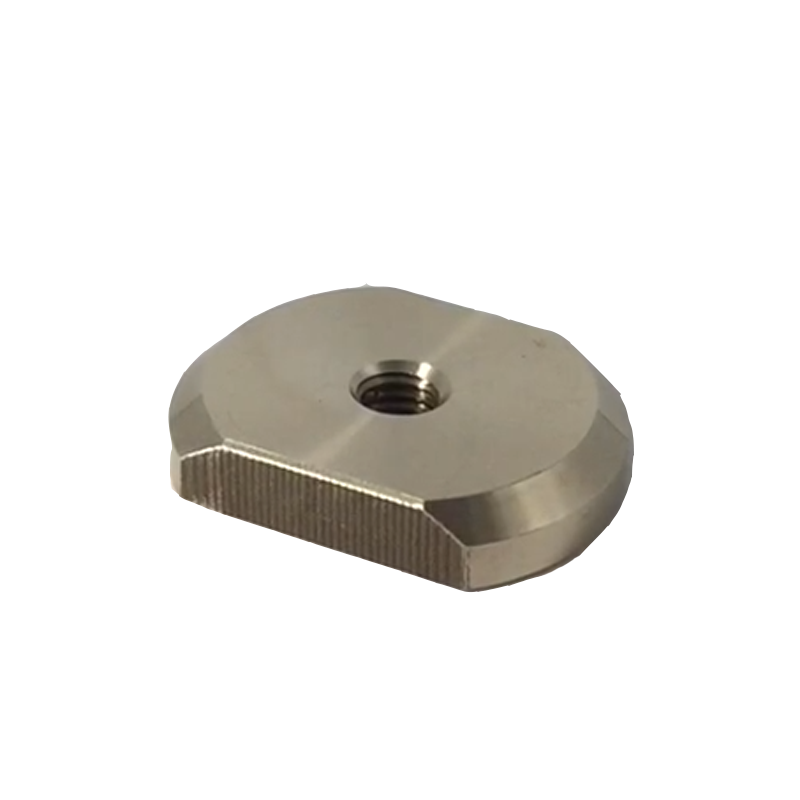

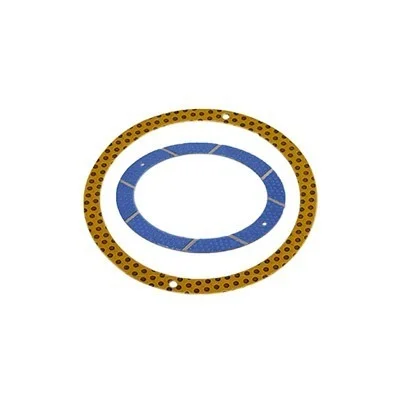

MYWAY Thrust Washers Product List

What is Thrust Washer?

A thrust washer, also referred to as a thrust bearing or thrust plate, is a flat, disk-shaped mechanical component specifically engineered to manage axial loads—forces that act parallel to a shaft’s axis of rotation. Unlike radial bearings that support weight perpendicular to the shaft, the thrust washer’s primary function is to provide a low-friction, wear-resistant interface that absorbs these axial forces. It prevents unwanted lateral movement of a rotating shaft or assembly, maintaining precise alignment and preventing metal-on-metal contact that leads to rapid wear and failure. Characterized by its simple, often thin profile, it is a fundamental and cost-effective solution for controlling thrust in a vast array of machinery, from automotive engines to heavy industrial gearboxes.

Constructed from specialized materials, modern thrust washers often utilize metal-polymer composites or fiber-reinforced polymers like PTFE. This design incorporates a robust steel backing for strength, paired with a self-lubricating polymer surface layer, enabling reliable performance even in dry or marginally lubricated conditions. Its key advantages include excellent shock and load capacity, reduced maintenance needs, and corrosion resistance. This makes it an indispensable component in critical applications such as automotive transmissions (e.g., crankshaft positioning), industrial pumps, cranes, and valve actuators, where managing axial force is crucial for system longevity and safety.

Based on the differences in material composition and application characteristics of our product series, we offer components in standard materials and standard specifications. Additionally, we can develop and design customized, non-standard products according to the specific purposes and operating conditions provided by our customers. Should you have any needs, please feel free to contact us at any time.

Thrust Washers Explained: A Complete Guide for Reliable Axial Load Management

In high-load rotating machinery, a component as thin as a coin often determines the entire system’s reliability. That component is the thrust washer. Unlike radial bearings, thrust washers are the unsung heroes that manage forces pushing along a shaft’s axis. When these forces are not properly controlled, they lead to catastrophic wear, alignment failure, and unplanned downtime. This article breaks down everything you need to know about thrust washers—from how advanced materials prevent failure to choosing the right type for your application—and highlights how precision manufacturers like MYWAY are engineering solutions for longer-lasting performance.

Understanding the Critical Role of Thrust Washers

At its core, a thrust washer is a flat or sometimes slightly conical bearing designed to support axial (thrust) loads in rotating assemblies. Think of a crankshaft in an engine trying to move forwards or backwards, or the immense axial force on a wind turbine’s main shaft. The primary job of a thrust washer is to provide a low-friction, wear-resistant surface that absorbs this force, preventing metal-on-metal contact and maintaining precise component alignment.

While simple in appearance, their function is vital. The global market for thrust and spherical plain bearings was valued at approximately $1.45 billion in 2024 and is on a steady growth path, underscoring their fundamental role across industries. They are indispensable in:

Automotive Transmissions and Engines: Managing clutch engagement forces and crankshaft positioning.

Industrial Gearboxes and Pumps: Supporting gears and impellers under heavy axial loads.

Heavy Machinery (Cranes, Mining): Withstanding shock loads and high pressures.

Aerospace and Wind Energy: Offering lightweight, reliable solutions in demanding environments.

Beyond a Simple Spacer: How Modern Thrust Washers Work and Prevent Failure

Many engineers understand the “what” but often overlook the “how,” which is where failures originate.

The Common Pitfalls: Why Thrust Washers Fail

Traditional thrust washers often succumb to two primary issues: loss of effective lubrication and the resulting high interface temperatures. Inadequate lubrication leads to boundary friction, generating heat that can soften materials, accelerate wear, and even cause seizure. Contamination, misalignment, and overloads exacerbate these problems, leading to premature failure and costly repairs.

The Engineering Solution: Hydrodynamic and Material Innovation

To combat these issues, modern thrust washer design focuses on two fronts: enhancing lubrication and using advanced materials.

Hydrodynamic Groove Design: Cutting-edge designs feature engineered grooves on the washer’s face. These aren’t just for oil distribution; they are precision-shaped to actively generate a pressurized fluid film. For example, grooves with a convex or elliptical lead-in radius are proven to build more pressure at the inlet, creating a thicker, more stable lubricant layer that separates the surfaces even under severe conditions. This shifts operation into a hydrodynamic regime, drastically reducing friction and wear.

Advanced Self-Lubricating Composites: For applications where oil lubrication is impractical or where maintenance must be minimized, self-lubricating materials are the answer. These are typically metal-polymer composites, structured in layers:

A Steel Backing: Provides mechanical strength and heat dissipation.

A Porous Bronze Interlayer: Sintered onto the steel, it acts as a reservoir.

A Polymer-Based Sliding Layer: Materials like PTFE (Teflon), POM (Acetal), or Polyamide-imide are impregnated with lubricants (like graphite or MoS2). This layer provides an inherently low-friction surface.

During operation, a thin film of the lubricant from this sliding layer transfers to the mating surface, creating a slick, protective barrier that operates reliably with little to no external lubrication.

Choosing the Right Thrust Washer: A Material Comparison

Selecting the wrong material is a direct path to failure. Here’s a comparison of common thrust washer types:

| Feature | Sintered Bronze (Oil-Impregnated) | Bimetal (Steel-backed Babbitt) | Metal-Polymer Composite (e.g., PTFE/POM) | High-Performance Polymer (e.g., PEEK, Torlon) |

|---|---|---|---|---|

| Key Strength | Good load capacity, cost-effective, self-lubricating to a degree. | Excellent conformability and embeddability, good surface treatment for startup. | Excellent dry-running capability, very low friction, resistant to corrosion and chemicals. | High temperature resistance, excellent mechanical strength, good chemical resistance. |

| Primary Weakness | Limited dry-run capability, lower temperature range. | Poor fatigue strength at high temps, requires robust lubrication. | Lower maximum continuous operating temperature (~120°C to 150°C for many grades). | Higher cost, requires precise design for thermal expansion. |

| Ideal For | General industrial applications with intermittent lubrication. | High-speed, oil-lubricated applications like automotive engines. | Low-maintenance, dry or marginally lubricated systems, food & beverage, dirty environments. | High-temperature, high-precision applications in aerospace, automotive transmissions. |

| Machinability | Good | Good | Excellent; composites are easy to cut to exact tolerances. | Fair to good; requires specific tooling. |

Design and Selection Guide for Optimal Performance

Choosing a thrust washer is more than picking an inner and outer diameter. Follow this actionable checklist:

Define Operating Conditions:

Axial Load (kN): Steady, dynamic, or shock load?

Speed (RPM): Surface speed is critical for heat generation.

Temperature Range (°C): Consider both ambient and operational heat.

Lubrication: Continuous oil, grease, or dry running?

Environmental & Application Factors:

Misalignment: Will the faces remain parallel? Some materials tolerate misalignment better.

Contamination: Is exposure to dirt, water, or chemicals likely?

Space Constraints: What are the limits on washer thickness (e.g., 1.5mm – 2mm is common for compact designs)?

Calculate and Verify:

Surface Pressure (P): Load / Contact Area. Ensure it’s within the material’s limits.

PV Value: Pressure (MPa) x Velocity (m/s). This is the key metric for wear. Your chosen material’s maximum PV must not be exceeded.

Consult an Expert: For critical applications, leverage the engineering support of your manufacturer.

The MYWAY Advantage: Precision, Performance, and Partnership

At MYWAY, we understand that a thrust washer is a critical system component, not just a commodity part. Our expertise extends beyond manufacturing into precision engineering and problem-solving.

We specialize in producing high-performance metal-polymer composite thrust washers and bushings tailored to challenging applications. By leveraging advanced self-lubricating composites and precise CNC machining, we deliver components that offer:

Extended Service Life: Reduced friction and built-in lubrication dramatically lower wear rates.

Maintenance Reduction: Ideal for sealed-for-life or hard-to-reach assemblies.

Reliability in Harsh Conditions: Excellent performance in contaminated or poorly lubricated environments.

Custom Solutions: We don’t just sell standard sizes; we engineer solutions. Whether you need a specific material blend, unique groove pattern for hydrodynamic lift, or a custom geometry to fit a tight envelope, our engineering team can partner with you from design to production.

Ready to Solve Your Thrust Load Challenges?

Stop compromising with off-the-shelf solutions that might not meet your specific demands. Let MYWAY’s engineering expertise provide you with a thrust washer solution designed for reliability and longevity.

Contact us today for a technical consultation or a competitive quote on your next project.

Frequently Asked Questions (FAQs)

Q: Can a thrust washer be used without any lubrication?

A: Yes, but only if it’s made from a proper self-lubricating material like a PTFE-based metal-polymer composite. Traditional bronze or steel washers will fail quickly without lubrication.

Q: What’s the difference between a thrust washer and a thrust bearing?

A: The terms are sometimes used interchangeably, but “thrust bearing” often refers to assemblies with rolling elements (balls, rollers). “Thrust washer” typically denotes a plain (sliding) bearing without rolling elements, making it more compact and often more cost-effective for certain load and speed ranges.

Q: How do I know if my thrust washer has failed?

A: Common signs include increased noise or vibration, excessive axial play (movement along the shaft), metal particles in the oil, or visible scoring and overheating on the washer and mating surface.

Q: Can you machine custom thrust washers from special materials?

A: Absolutely. At MYWAY, custom machining is a core service. We work with a variety of advanced composites, high-performance polymers, and bronze alloys to produce washers to your exact specifications, including unique IDs/ODs, thicknesses, and groove patterns.

Q: Are polymer-based thrust washers strong enough for heavy machinery?

A: Modern engineering polymers like Polyamide-imide (e.g., Torlon) are exceptionally strong and are specifically used in demanding automotive and industrial applications. When designed correctly with a proper steel backing for support, they can support significant loads while offering benefits like weight savings and corrosion resistance.