MYWAY Bushing: Heavy-Duty Truck Differential Thrust Washer Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

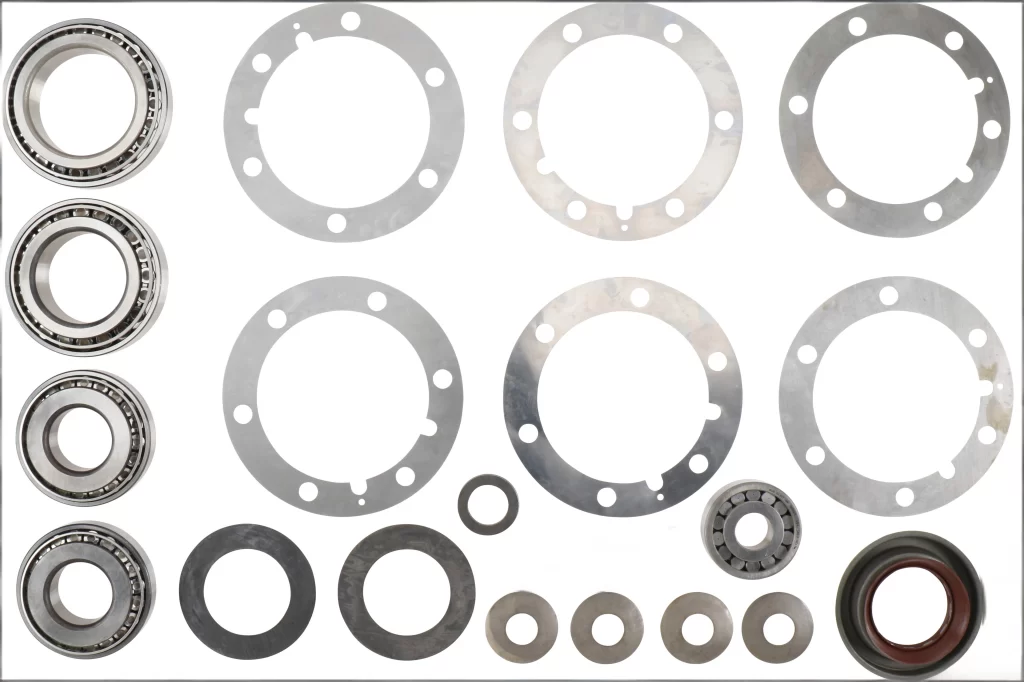

MYWAY Truck Differential Thrust Washer

THRUST WASHER, differential pinion

THRUST WASHER, differential pinion MGA Differential & Axles Rear Axle 13 THRUST WASHER 1500, 1600, 1622 2 MGB Differential & Axles Banjo Type Rear Axle 13 THRUST WASHER 1962-67 (Banjo Axle) 2 MGB Differential & Axles Tubed Type Rear Axle 67 THRUST WASHER 1965-80 (Tube Axle) 2 MGC Differential & Axles Tubed Type Rear Axle 67 THRUST WASHER 1968-69 2

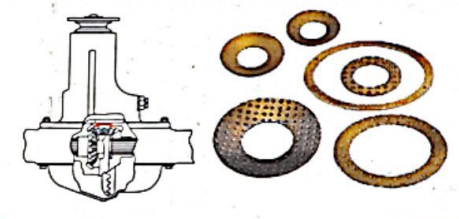

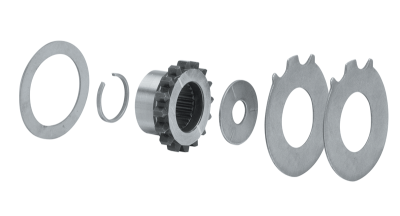

Differential Spider Gear Thrust Washer, Small Conical Fits 46-71 Jeep & Willys with Dana 41/44/53

New Differential Spider Gear Thrust Washer, Small Conical (2 required) Application: Dana 41/44/53 rear Fits: 46-49 CJ-2A 49-53 CJ-3A 53-64 CJ-3B 55-71 CJ-5 50-52 M38 52-71 M38A1 46-64 Truck 46-64 Station Wagon

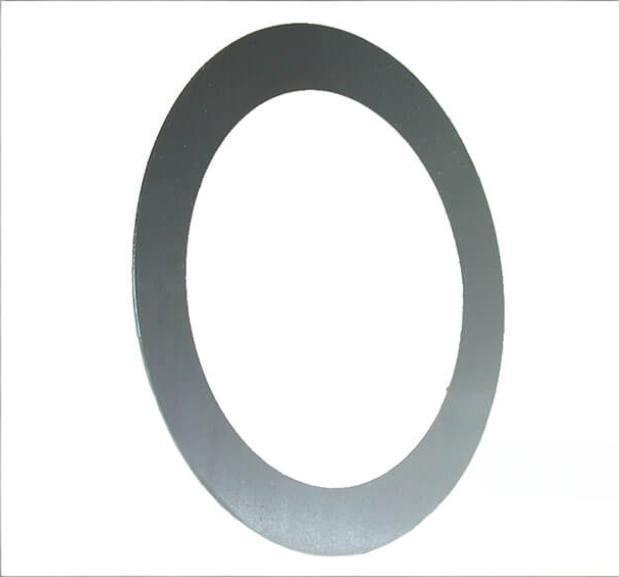

Differential Side Gear Thrust Washer

Material: Steel Outer Dia.: 2.188" Inner Dia.: 1.410" Thickness: 0.031"

Rear Differential Carrier Thrust Washer for John Deere Equip

Thrust Washer for Differential Spider Gear for John Deere

THRUST WASHER SIDE GEAR

THRUST WASHER SIDE GEAR HD Differential > THRUST WASHER, SIDE GEAR INTERCHANGES: REPLACES Mack: 25100250 REPLACES PAI: 3071 REPLACES World American: 38KH215 REPLACES World American: 38KH218A REPLACES PAI: BWA-3071 REPLACES S&S Truck Parts: S-7637

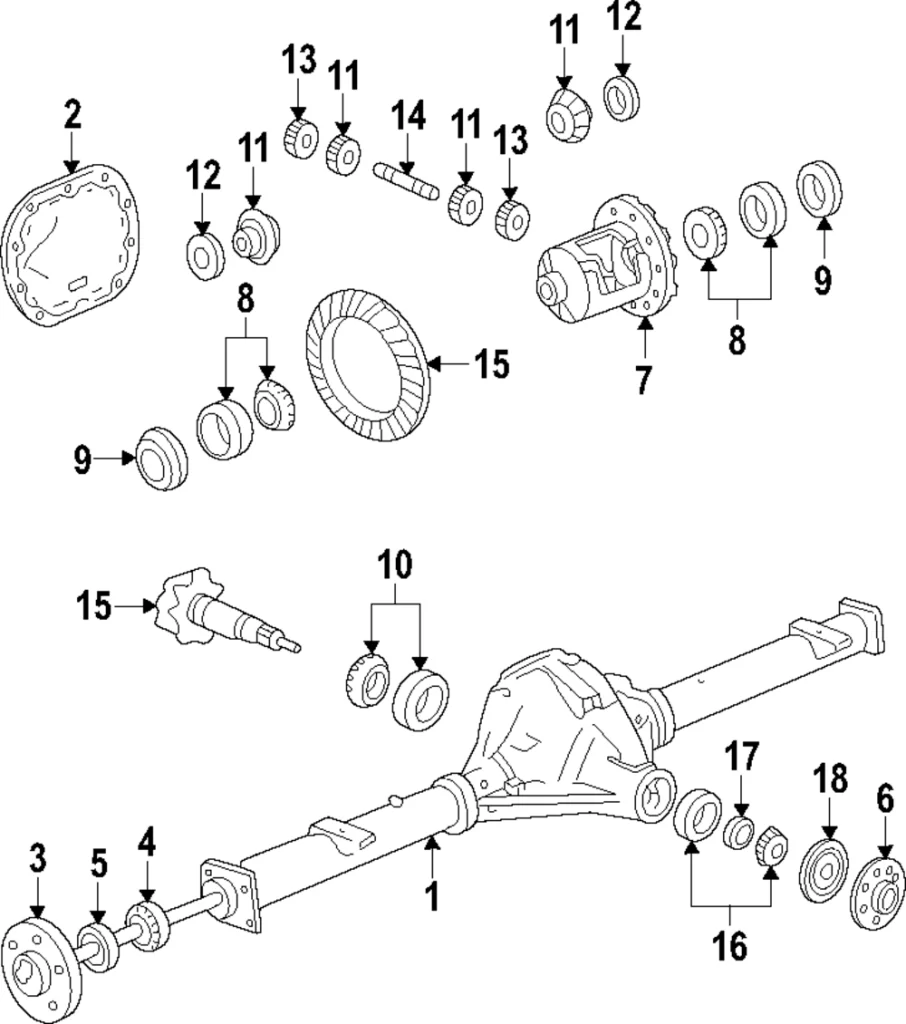

QU40041 Dana Axle Differential Side Gear Thrust Washer

QU40041 Dana 60, Dana 70, Dana 80 Axle Differential Side Gear Thrust Washer is a genuine Dana-Spicer part that fits most Model 60 and Model 70 front or rear axles with open differentials. QU40041 also fits most Dana 80 open differential rear axles. Use 2 per axle. USA Made. Most Dana-Spicer Model 60 and 70 axles with open differentials except for 1994, 1995, 1996, 1997, 1998, 1999, 2000, 2001, 2002 Dodge Ram front axles.

Spicer 027810 - Differential Thrust Washer

SKU: EAP027810 Brand: EATON AXLE Weight: 0.15 LBS Mfr Part Number: 027810 Inside Diameter: 1.01 Outside Diameter: 2.36 Thickness: 0.01

Differential Thrust Washer for Renault Truck Spare Parts 5010534114

Model NO. For Renault Heavy Truck Part Name Renault Thrust Washer MOQ 1 PCS Size OEM Standard Size Truck Model Heavy Duty Truck Parts Certification SGS

Cadillac CTS-V Rear Differential Thrust Washer Kit

Weight 0.2 lbs Dimensions 6 × 6 × 1 in

Differential Pinion Gear Thrust Washer

Differential Part Side Gear Thrust Washer 42101765 116143

Application:for Iveco Replaces Ref. No. Iveco 42101765 Iveco 116143

Differential Side Gear Thrust Washer

Meritor RD20145 Differential Thrust Washer - 1229S4985

Item Tag #: MER 1229S4985 Assembly Info: Meritor RD20145 Type: Aftermarket / Replacement Item Info: Meritor 1229S4985

VOLVO TRUCK Thrust Washer differential pinion 1523186

Products Name: Thrust Washer differential pinion OEM NO.: 1523186 Used in vehicles: VOLVO TRUCK OE NUMBER VOLVO 1523186

10000+ Types of Truck Differential Thrust Washers – Contact Us for Details

| Component Category | Specific Type / Model / Material |

|---|---|

| Truck Differential Thrust Washer | Copper, Steel |

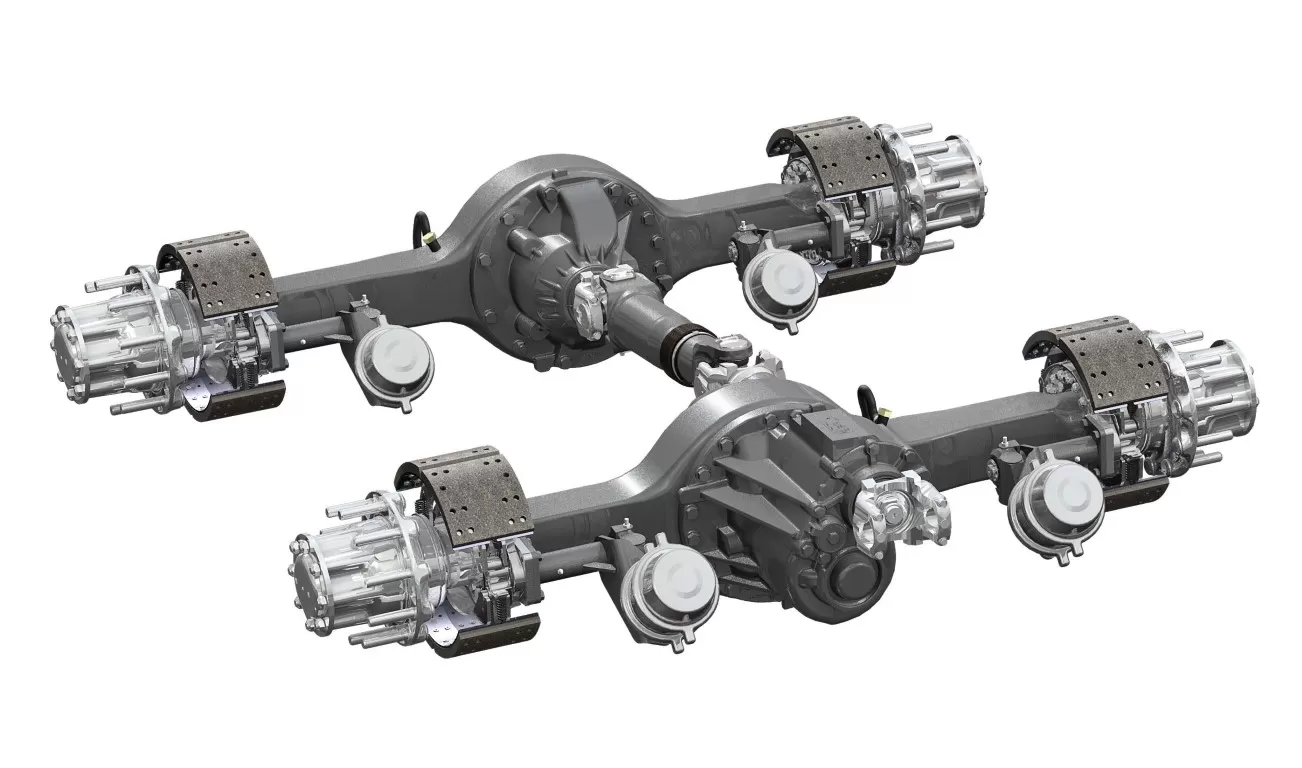

How Advanced Thrust Washers Solve the Biggest Wear Problem in Your Truck's Differential

In the demanding world of heavy-duty trucking, every component is pushed to its limit. While engines and transmissions get most of the attention, the relentless punishment of hauling massive loads is often felt first in the drivetrain’s unsung heroes. Among them, the differential thrust washer plays a surprisingly pivotal role. It’s a simple-looking ring, yet its failure can cascade into catastrophic and costly repairs. This guide delves into why this component is critical, how materials technology is revolutionizing it, and what you should look for to ensure maximum longevity and minimum downtime for your fleet.

What Is a Differential Thrust Washer and Why Does It Matter?

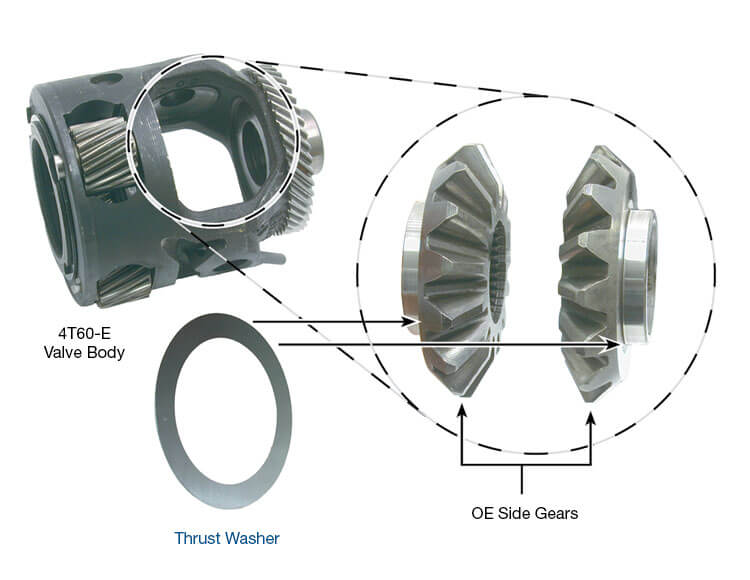

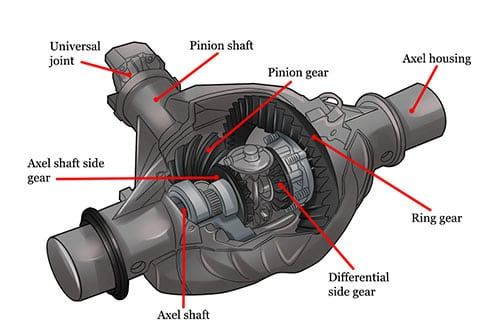

A thrust washer is a ring-shaped component installed within the differential assembly. Its primary role is to manage axial loads—the side-to-side forces generated by the gears. Positioned between the rotating differential gears (the side gears and pinion gears) and the stationary differential housing, it serves three vital functions:

Reduce Friction and Improve Efficiency: It provides a dedicated, low-friction surface for gears to rotate against, preventing metal-on-metal contact with the housing and improving power transfer efficiency.

Protect Critical Surfaces: It acts as a sacrificial layer, absorbing wear to protect the much more expensive differential case and gear surfaces from scoring and damage.

Maintain Gear Alignment: By controlling axial play, it ensures gears remain in perfect mesh. Proper alignment is crucial for smooth operation, reduced noise, and preventing premature gear tooth failure.

When a thrust washer wears out or fails, the consequences are severe. Excessive gear movement leads to misalignment, increased backlash, and loud knocking noises. Ultimately, unprotected gears grind against the housing, leading to metal contamination in the gear oil and total differential failure. For a heavy-duty truck, this means unplanned downtime, a costly rebuild, and lost revenue.

The Material Evolution: From Traditional Metals to Advanced Composites

The quest for the ideal thrust washer has driven significant material innovation, as shown in the table below:

| Material Type | Common Examples | Key Advantages | Limitations & Challenges |

|---|---|---|---|

| Sintered/Machined Metal | Bronze, Copper-Iron, Alloy Steel | High load capacity, good heat dissipation, familiar technology. | Requires constant lubrication, can score mating surfaces if lubricant fails, heavier. |

| Engineering Plastics | PA66 (Nylon), Acetal | Lightweight, corrosion-resistant, some self-lubricating properties. | Limited load capacity and thermal tolerance, can creep under constant high load. |

| High-Performance Polymers | PEEK, Torlon | Excellent wear resistance, high temperature tolerance, maintains strength. | Significantly higher material cost, may still require lubrication in extreme duty cycles. |

| Advanced Composites (The Modern Solution) | Steel-Polymer Laminates (e.g., MYWAY’s design) | Self-lubricating, high load-bearing steel backing, excellent wear life, corrosion resistant. | Manufacturing process is more complex than single-material washers. |

The industry trend is clearly moving towards lightweight, high-performance solutions that reduce or eliminate maintenance. Replacing traditional steel with advanced plastics like PEEK can dramatically cut weight while boosting durability. However, the most robust solution for heavy trucks lies in composite materials that marry the strength of metal with the low-friction properties of advanced polymers.

Innovation in Design: The MYWAY Advantage in Thrust Washer Technology

Moving beyond material choice, true innovation lies in layered engineering. At MYWAY, we design thrust washers not as simple parts, but as integrated self-lubricating systems. Our proprietary three-layer composite structure solves the core problems of friction, wear, and heat:

High-Strength Steel Backing (0.7–2.3mm): This layer provides the structural integrity to withstand the immense axial loads from truck differentials. It ensures dimensional stability under pressure and offers excellent heat conductivity to dissipate operational warmth.

Sintered Copper Interlayer (0.20–0.3mm): This porous metallic matrix is permanently bonded to the steel. It dramatically enhances the bond with the top layer and further improves heat dissipation, a critical factor in high-torque applications.

PTFE-Based Sliding Layer (0.01–0.03mm): This is the working surface. A precision-blend of Polytetrafluoroethylene (PTFE) and other elements creates an ultra-low-friction layer. During operation, a tiny amount transfers to the mating gear surface, forming a protective, lubricating film that drastically reduces wear on both the washer and the gear itself.

This “Metal-Polymer Self-Lubricating” design means the thrust washer performs optimally from the first turn, significantly extending service intervals and protecting your differential’s core components.

Engineering Excellence and Precision Manufacturing

A superior design is only as good as its execution. MYWAY’s manufacturing philosophy is rooted in precision, consistency, and scalability, directly translating to reliability for your fleet.

Unmatched Precision: We operate over 200 dedicated precision machining centers. Processes like fine turning, drilling, and milling oil grooves are executed with tolerances as tight as ±0.001mm, ensuring every thrust washer fits perfectly and functions as designed.

Rigorous Process Control: Our production uses tungsten steel precision molds and automated sintering furnaces. Every material strip is laser-measured, guaranteeing thickness tolerances within +0.01mm for absolute consistency.

Proven Capacity for Demand: With a monthly output capacity of 200 tons, we are equipped to support both large OEM orders and the aftermarket needs of major fleet operators, ensuring timely supply without compromising quality.

Upgrade Your Fleet’s Foundation with MYWAY Precision

Don’t let a small, inexpensive component dictate the lifespan of your most valuable drivetrain assets. The shift to advanced, self-lubricating composite thrust washers isn’t just an upgrade—it’s a strategic decision for reducing unscheduled downtime, lowering total operating costs, and maximizing vehicle availability.

MYWAY combines cutting-edge material science with uncompromising manufacturing precision to deliver thrust washer solutions you can rely on for the long haul.

Frequently Asked Questions (FAQ)

Q1: How often should differential thrust washers be inspected or replaced?

A: There’s no universal mileage. Inspection during every major drivetrain service (e.g., during gear oil changes) is recommended. Look for metal particles in the oil or listen for new gear whine/knocking. With MYWAY’s composite washers, the service interval is significantly extended compared to traditional materials.

Q2: Can I use any thrust washer that fits the dimensions?

A: No. Using a washer with incorrect material properties, hardness, or thickness can lead to rapid failure. It’s crucial to use a part specified for the load, speed, and thermal conditions of a heavy-duty truck application. MYWAY’s products are engineered specifically for these severe-duty cycles.

Q3: What are the signs of a failing thrust washer?

A: The most common symptoms are increased gear noise (whining or knocking), noticeable play or backlash in the drivetrain, and the presence of excessive metallic debris on the magnetic drain plug during an oil change.

Q4: Do MYWAY’s self-lubricating thrust washers require any special grease during installation?

A: No, that’s a key advantage. Our washers are designed for dry installation. The PTFE-based sliding layer provides immediate lubrication upon startup. Applying grease can actually attract dirt and impede the formation of the optimal transfer film.

Q5: Can you produce custom thrust washers for specific or prototype applications?

A: Absolutely. Our engineering team specializes in developing custom solutions. We can work with your specifications for unusual sizes, unique mounting requirements, or specialized performance needs (e.g., extreme temperature or corrosion resistance).