MYWAY Bushing: Heavy-Duty Truck Knuckle Bushing Solutions

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Truck Knuckle Bushing

Steering Knuckle Bushing Solid L/R for Toyota Truck Van 1986-1995 90381-30006

New: A brand-new, unused, unopened, undamaged item in its original packaging (where packaging is ... Read moreabout the condition Fitment Type Direct Replacement Type Knuckle Bushing Placement on Vehicle Left, Right Manufacturer Part Number 90381-30006 Year 1986 1987 1988 1989 1990 1991 1992 1993 1994 1995 Manufacturer Warranty Yes

Steering knuckle bushing 50 x 57 x 50 bottom

Steering knuckle bushing 50 x 57 x 50 bottom

Truck Parts Steering Knuckle Bushing 1880410029 for Sinotruk HOWO

SINOTRUK (CNHTC) HOWO A7 2006- SINOTRUK (CNHTC) HAOJUN 2005- Brand Name SSNTECH Model Number 1880410029 OEM No 1880410029 Product name Steering Knuckle Bushing Single item Single package size 5X5X5 cm Single gross weight 2.000 kg

Shacman F2000 Truck Parts Steering Knuckle Bushing 81.93020.0706

Model NO. 81.93020.0706 Type: Steering Knuckle Truck Model: 70mineking

Foton Truck Bus Spare Parts Steering Knuckle Bushing L130000000004-17/L130000000004-18

product name Steering knuckle bushing Product number L130000000004-17/L130000000004-18 Specification standard Material Metal performance hight Application classification steering system Applicable models Truck and bus

BUSHING, STEERING KNUCKLE (0311276080)

PRIMARY DIVISION TRAILER PART NUMBER'S 311276080

Tapered Adapter Bushing, 0.750" Tie Rod End to Rockwell Steering Knuckle

Use the TRB10 Tapered Adapter Bushing to adapt 0.750" Tie Rod Ends to a Rockwell Steering Knuckle

Sinotruk HOWO Parts Steering Knuckle Bushing 1880410035

Model NO. 1880410035 Type Steering Gears/Shaft Material Steel Certification ISO Automatic Specification Packing150*45cm

QU42016 Tapered Split Steering Arm to Steering Knuckle Bushing

QU42016 Tapered Split Steering Arm to Steering Knuckle Bushing for Dana 44 and GM 10 bolt Open Knuckle front axles. Sold individually, order 3 per axle.

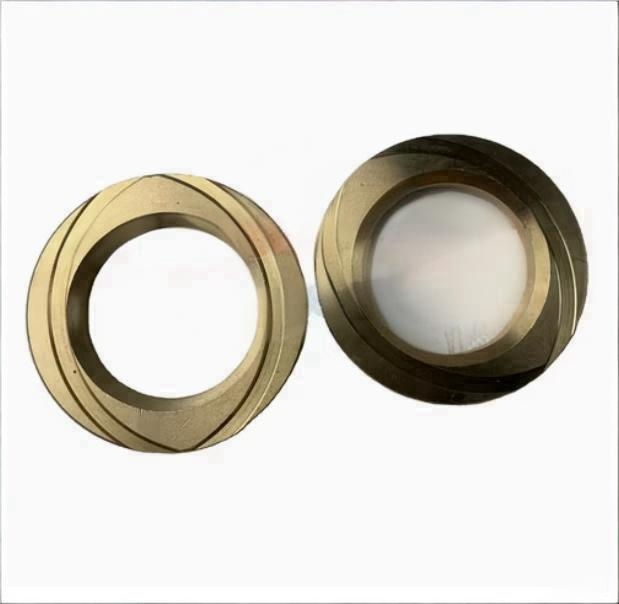

4Pcs Steering Front Knuckles Flange Brass Bushing for Axial SCX10 RC Car #1140

Apply to Axial Wraith AX90018 90020 Quantity : 4PCs Material : Brass Inside diameter: Φ 3 mm Outside diameter: Φ 4.7 mm Height: 6.7 mm

BUSHING, STEERING KNUCKLE (5010308715 – 7485132324)

PRIMARY DIVISION TRUCK PART NUMBER'S 5010308715, 7485132324

HD95009410054-XLBCK Steering Knuckle Repair Kit- Howo Truck Parts

Steering Knuckle Bushing 90381-35001 for Toyota Landcruiser Hzj79 79 Series

Model NO. 90381-35001 Package Size 10.00cm * 10.00cm * 10.00cm Package Gross Weight 10.000kg

Truck Steering Knuckle Bush 30Z01-01020 30Z01-01019

Model Number 30Z01-01020 Car Make Truck Model Number 30Z01-01020 Single package size 40X20X20 cm Single gross weight 1.000 kg

90381-33002 9038133002 High Quality Auto Part OEM for Toyota Runner Truck Steering Knuckle Bush LeftRight 90381-33002 9038133002

OE NO. 90381-33002, 9038133002 Purpose for replace/repair Size Standard Car Model For Toyota Condition New Application Auto Part Product name Engine Mouning OEM NO 90381-33002 9038133002 size Packaging and delivery Selling Units Single item Single package size 2X2X2 cm Single gross weight 0.500 kg

10000+ Types of Truck Knuckle Bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

| Steering Knuckle | Steering Knuckle Bushings | Bimetal |

Guide to Truck Knuckle Bushings and Why They Deserve Top-Quality Replacements

A single worn bushing in a truck’s steering knuckle can introduce up to 0.5 inches of steering play, a seemingly small gap that dramatically increases stopping distances and tire wear.

Have you ever heard a loud clunk from the front end when going over a bump, or felt the steering wheel shimmy unexpectedly on the highway? As a truck owner or fleet manager, these aren’t just annoyances — they’re often the first cries for help from a critical but overlooked component: the steering knuckle bushing.

This guide will explain everything you need to know about truck knuckle bushings — their function, failure signs, and, most importantly, why choosing a premium replacement like MYWAY’s advanced bushing solutions is a smart investment in safety and cost savings.

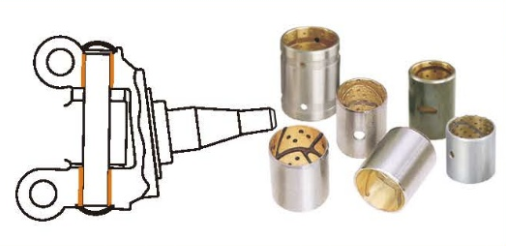

The Core of Steering: What is a Truck Knuckle Bushing?

Let’s start with the basics. The steering knuckle itself (often called the “upright” or “hub carrier”) is the complex metal piece that connects your wheel and hub to the rest of the suspension and steering system. It’s the crucial pivot point that allows your wheels to both turn for steering and move up and down over bumps.

The knuckle bushing is the component that facilitates this pivoting motion. Specifically, it’s the bearing or bronze bushings pressed into the knuckle’s eye, through which the king pin or ball joint stud passes. This setup allows the knuckle to rotate smoothly around the pin when you turn the steering wheel.

Its core functions are:

Providing a Low-Friction Pivot: It enables smooth rotation for easy steering.

Absorbing Shock and Vibration: It dampens impacts from road imperfections before they reach the steering wheel.

Maintaining Precise Alignment: It keeps the king pin securely positioned, which is fundamental for preserving critical alignment angles like king pin inclination.

The High-Stakes Consequences of a Failing Bushing

A failing knuckle bushing doesn’t just wear out quietly. Its degradation directly attacks the truck’s stability and safety. Common symptoms include:

Excessive Steering Play and Wandering: The steering feels loose or vague, requiring constant small corrections to stay in a lane.

Knocking or Clunking Noises: Especially noticeable when turning or going over uneven surfaces, caused by metal components moving against each other.

Irregular or Accelerated Tire Wear: As alignment angles shift due to bushing wear, tires develop unusual wear patterns like cupping or feathering.

Reduced Steering Precision and Stability: The truck may feel unstable at higher speeds or when cornering.

The risks go beyond discomfort. Worn bushings can lead to king pin wobble, accelerating the wear on adjacent parts like tires and ball joints. In extreme cases, excessive play can compromise steering control, a severe safety hazard. A real-world parallel can be seen in high-profile incidents where steering knuckle failures on passenger vehicles led to safety recalls, underscoring the critical importance of the integrity of this entire assembly.

Material Matters: The Foundation of Bushing Performance

The performance and lifespan of a bushing are largely determined by its material composition. Common materials include:

Bronze/Copper Alloys: Traditional and widely used for their good wear resistance and load-bearing capacity. The bronze bushing mentioned in foundational texts is a classic example.

Sintered Metal: Powdered metal fused together, often used for OEM applications, offering a balance of strength and self-lubrication.

Polymer Composites: Modern materials that can offer excellent noise, vibration, and harshness (NVH) damping.

Advanced manufacturing constantly pushes the envelope. For example, research into using ultra-fine spheroidal graphite cast iron for knuckles themselves focuses on optimizing the trade-off between structural rigidity and thermal performance. Similarly, innovations like 3D additive manufacturing are being explored to create parts with integrated, optimized rib structures for superior strength. While these focus on the knuckle body, they highlight the industry’s move toward precision-engineered materials for critical chassis components — a philosophy that applies equally to the bushings within them.

Introducing the MYWAY Premium Truck Knuckle Bushing Solution

At MYWAY, we’ve applied this same philosophy of advanced material science and precision engineering to our aftermarket knuckle bushings. We understand that a bushing is not just a simple ring of metal; it’s a vital wear component that protects your more expensive steering and suspension parts.

Why Choose MYWAY Bushings?

Our bushings are engineered to be more than just a replacement — they are an upgrade in reliability. Here’s how we achieve that:

Superior Material Formulation: We use proprietary, high-density alloy blends designed for the commercial trucking environment. Our materials are selected for exceptional wear resistance, reducing the frequency of replacements.

Optimized for Load and Longevity: Trucks carry heavy loads, and their front axles bear significant stress. MYWAY bushings are specifically tested and validated to handle these heavy-duty conditions, maintaining integrity and performance over the long haul.

Precision Manufacturing: Each bushing is manufactured to exacting tolerances. A perfect fit ensures correct king pin alignment from installation, preventing premature wear on the pin itself and the new bushing.

Engineered for the Real World: We design our bushings to effectively dampen vibration and resist the ingress of contaminants, contributing to a smoother drive and extended component life.

Comparison: Standard vs. MYWAY Bushing

| Feature | Standard/Generic Bushing | MYWAY Premium Bushing |

|---|---|---|

| Primary Material | Common bronze or sintered metal | Proprietary high-density, wear-resistant alloy |

| Load Capacity | Meets basic specifications | Engineered for sustained heavy-duty loads |

| Wear Resistance | Standard | Enhanced, for longer service intervals |

| Fit & Tolerance | Acceptable | Precision-engineered for optimal king pin alignment |

| Design Focus | Replacement part | Reliability and performance upgrade |

| Impact on Adjacent Parts | Standard protection | Helps extend the life of king pins and tires |

Beyond the Bushing: Installation and Proactive Maintenance

Installing a new knuckle bushing is a professional job that requires specialized tools like a hydraulic press, as well as knowledge of proper torque specifications and alignment procedures. Incorrect installation can damage the new bushing or the knuckle immediately.

The best strategy is proactive, preventative maintenance. Incorporate bushing inspection into your regular service schedule. Look for:

Visible cracks, tears, or excessive wear on the bushing surface.

Any movement or play between the king pin and the knuckle.

Signs of excessive grease leakage, which may indicate seal failure.

Addressing worn bushings early is always cheaper than repairing the cascade of damage they can cause.

Frequently Asked Questions (FAQ)

How often should truck knuckle bushings be replaced?

There’s no single mileage interval. Replacement should be based on condition, not just time. They should be inspected during every major suspension service or if any of the symptoms mentioned earlier (play, noise, tire wear) appear. In severe duty cycles, inspections should be more frequent.

Can I replace just the bushing, or do I need a whole new steering knuckle?

In most traditional truck designs, the bushing is a replaceable component pressed into the knuckle. As long as the knuckle itself is not cracked, scored, or otherwise damaged, pressing in a new, high-quality bushing like MYWAY’s is a standard and cost-effective repair. Always have a professional inspect the knuckle for integrity before proceeding.

What are the signs that my bushings need immediate attention?

The need for immediate attention is signaled by: 1) Audible and frequent clunking when steering or hitting bumps, 2) Visibly abnormal and rapid tire wear, and 3) A pronounced feeling of looseness or instability in the steering, especially at speed. Do not ignore these warnings.

Why are MYWAY bushings priced higher than some generic alternatives?

The price reflects the value in extended service life, performance, and protection. Think of it as an investment: a slightly higher initial cost for a part that lasts longer, maintains proper alignment to save your tires, and protects expensive adjacent components from accelerated wear. This leads to lower total operating costs and less downtime over the life of your truck.

How can I source MYWAY bushings for my fleet?

MYWAY premium chassis components are available through authorized distributors and directly for fleet operations. For a consultation, specific pricing, or to discuss compatibility with your truck models, contact our technical sales team today. Let us help you specify the right part for enhanced reliability.

Ready to eliminate steering play and protect your investment? Get a quote for MYWAY heavy-duty knuckle bushings tailored to your fleet’s needs now.