MYWAY: Your Professional Guide to Leaf Spring Bushing Manufacturers in China

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

MYWAY Leaf Spring (Laminated Spring) Bushing

Bimetal Leaf Spring Bushings

BiMetal Leaf Spring Bushings

Replace: K7129100 Contains: 16 PCS Trailer Leaf Spring Bushing Size: Inside Diameter:9/16", Outside diameter: 11/16" Length: 1-3/4" MATERIAL: Our leaf spring bushings are made of brass, which is wear-resistant, temperature-resistant, durable and not easy to oxidize, deform or corrode MATCHING: The leaf spring release bushing kit is precisely manufactured according to the original vehicle parameters to ensure a perfect match with your vehicle

Leaf Spring Bushings

Leaf Spring Bushings

Part Type: Leaf Spring Bushings Product Line: Superlift Leaf Spring Bushings Summit Racing Part Number: SLF-315 UPC: 804260008260 Frame Shackle Bushing Outside Diameter (in.): 1.125 in. Main Eye Bushing Outside Diameter (in.): 1.125 in. Sleeve Included: Yes Bushing Material: Polyurethane Bushing Color: Black

Leaf Spring Bushings

Bronze Bushing Outside Diameter (A) = 11/16" Total Bushing Length (C) = 1-3/4" Inside Diameter (D) = 9/16" OEM# = 1407700 / 01407700 / 014-077-00 / K71-291

Leaf Spring Bushing Connecting Rod Bushing

Leaf Spring Bush

GST Registration Date 01-07-2017 Vehicle Type Truck Shape Cylindrical Material Brass Usage/Application Truck

Heavy Duty Truck Leaf Spring Bushing

Type Wheel Hub Bearing Color Color of Original Steel Max load capacity 150N/mm2 MOQ 500pcs Hardness 60-90HB Material Bimetal (Steel and Copper)

Bimetal Bushing Bearing Auto Parts Leaf Spring Bushes

Material steel+CuPb10Sn10+graphite Type sleeve Model Number TCB301 Brand Name TEHCO Single gross weight 5.000 kg Customized packaging (Min. order: 1,000 pieces) Customized logo (Min. order: 100 pieces) Graphic customization (Min. order: 1,000 pieces)

03.112.99.04.0 Bushing 0311299040 Leaf Spring BWP Brass Bushings

Maximum Pv 3 MPa·m/s Precision Rating g6 Structure Thrust Bearing Flange diameter 200-2800 Material Bronze Overall Length 20-900 Hardness HB 60-280 Model Number JDB-1U Maximum Temperature 400 Minimum Temperature -250 System of Measurement Metric Type Sliding Base Material Brass, bronze Lubricant Oil or grease Hardness 60-260 Bush types Cylinder, Collar, Thrust Waser, plates Application Automotive Mould, Plastic industry Certification ISO 9001:2015;IATF 16949:2016

Oil Lubricating Shaft Bush Harden Steel Bushing Bucket Pin and Bushing for Excavator hyundai

Material 45# 40Cr 20CrMo GCr15 Type Sleeve Model Number SN-H-1/SN-H-2 /SN-H-3 Product name Bushing Sleeve Material 45# 40Cr 20CrMo GCr15 Bush types Sleeve Processing method CNC processing Hardness 52-60HRC Working temperature -100~+350℃ Features Wear Resistance Outer diameter 35mm-350mm Application Excavators,Cranes,Construction Machine Single package size 25X10X10 cm Single gross weight 10.000 kg

Leaf Spring Trunnion Seat Bushing SZ384-00010 986700110 55523-Z2007 110x100x90 for hino Nissan Brand

Car Fitment Model Year Hino 500 2012- Hino 500 2015- Hino 500 2012-2015 Hino 500 2012-2021 Hino 500 2010-2021 Key attributes OE NO. SZ384-00010 986700110 55523-Z2007 Type Leaf Spring Material Steel Model Number SZ384-00010 986700110 55523-Z2007 Certificate ISO9008/TS16949 Application For Hino Trucks Warranty

JF Bimetallic Composite Sleeve Bearing Clutch and Leaf Spring Bushing King Pin Bearing

Material steel+bronze alloy Type Sleeve Inside Diameter Tolerance ±0.02 mm Lubrication Self-Lubricating Outside Diameter Tolerance ±0.02 mm Overall Length 50MM Model Number JF800 30x34x40mm Product name Clutch Bimetallic Bushing Certificate IATF 16949:2016 Item Leaf Spring Bushing Lubricating Grooves Keyword King Pin Bearing

JF Bimetallic Composite Sleeve Bearing Clutch and Leaf Spring Bushing King Pin Bearing

Material steel+bronze alloy Type Sleeve Inside Diameter Tolerance ±0.02 mm Lubrication Self-Lubricating Outside Diameter Tolerance ±0.02 mm Overall Length 50MM Model Number JF800 30x34x40mm Product name Clutch Bimetallic Bushing Certificate IATF 16949:2016 Item Leaf Spring Bushing Lubricating Grooves Keyword King Pin Bearing

JF Bimetallic Composite Sleeve Bearing Clutch and Leaf Spring Bushing King Pin Bearing

Material steel+bronze alloy Type Sleeve Inside Diameter Tolerance ±0.02 mm Lubrication Self-Lubricating Outside Diameter Tolerance ±0.02 mm Overall Length 50MM Model Number JF800 30x34x40mm Product name Clutch Bimetallic Bushing Certificate IATF 16949:2016 Item Leaf Spring Bushing Lubricating Grooves Keyword King Pin Bearing

High Strength Steel/Bronze Composite Bearing,Truck Leaf Spring Bushing for Heavy Duty Applications

Maximum Pv 15 MPa·m/s Structure Radial Bearing, Thrust Bearing Flange diameter 44-129.6mm Lubrication Grease/Oil Material Steel+Bronze Overall Length 10-100mm Construction works Maximum Temperature 260℃ Minimum Temperature -40℃ System of Measurement Metric Type Sliding Bearing/Plain Bearing Product Name Bimetallic Bearings Test Method ISO3547-2

10000+ Types of Leaf Spring (Laminated Spring) Bushings – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

| Suspension | Leaf Spring | Bimetal |

Complete Guide to Leaf Spring Bushings

What Is a Leaf Spring Bushing and Why Should You Care?

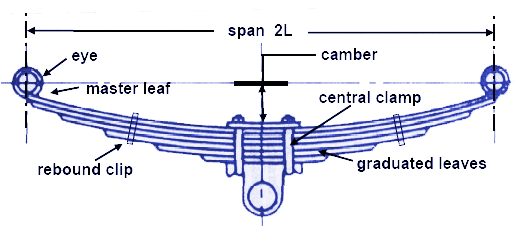

If you operate trucks, trailers, or any heavy-duty vehicle, you’re familiar with the crucial role of leaf spring suspension. This robust system, consisting of multiple curved steel plates, is the workhorse of the industry, bearing immense loads and absorbing road shocks. But there’s a small, often-overlooked component within this system that dictates its smooth operation, longevity, and your total cost of ownership: the leaf spring bushing.

A leaf spring bushing is a cylindrical sleeve pressed into the eyelets at each end of the leaf spring pack. It acts as the critical pivot point. A spring pin (or bolt) passes through this bushing, connecting the spring to the vehicle’s chassis or a swinging shackle. In essence, the bushing is the flexible joint that allows the leaf spring to articulate—compressing, extending, and twisting—as the vehicle travels over uneven ground, all while maintaining a secure connection.

Without a functional bushing, metal would grind against metal. Therefore, its primary job is to manage friction, dampen vibrations, and isolate noise. It transforms the harsh, rigid connection into a controlled, cushioned movement. When bushings fail, the problems quickly cascade: loud bangs and squeaks, imprecise axle alignment, accelerated wear on the spring eyes themselves, and a noticeably harsher ride that stresses every other component in the driveline.

The Critical Functions: More Than Just a Cushion

Understanding the bushing’s role requires a closer look at the leaf spring’s operation. In a longitudinal leaf spring rigid axle suspension, the spring does three jobs: it acts as the elastic element (spring), the positioning member (locating the axle), and partially as a damper. This multi-tasking places complex stresses on the connection points.

Articulation and Flexibility: When a wheel hits a bump, the leaf spring bends. Its ends need to move relative to the fixed frame points. The bushing’s elastic material allows for this angular twist and minor lateral shift, ensuring the spring can flex freely without binding.

Vibration and Noise Isolation: The constant friction between steel spring leaves is a known source of noise (often a “squeak” or “chatter”). The bushing, particularly those made from advanced compounds, acts as a barrier, preventing these high-frequency vibrations and noises from transmitting directly into the chassis and cabin.

Axle Alignment and Force Transmission: The bushing is not just a sponge; it must precisely locate the axle. It handles and transmits not just vertical loads but also horizontal thrusts and torques from acceleration, braking, and cornering. A worn, sloppy bushing can lead to axle walk or misalignment, causing unstable handling and irregular tire wear.

The Material Showdown: Rubber, Polyurethane, and Bronze

The performance of a leaf spring bushing is almost entirely defined by its material. The choice involves a classic engineering trade-off between comfort, durability, and cost.

| Material | Key Characteristics | Pros | Cons | Best For |

|---|---|---|---|---|

| Rubber (OE Standard) | Flexible, high damping, bonded to metal sleeves. | Excellent vibration isolation, quiet, cost-effective. | Degrades with ozone, oil, and weather; prone to cracking/tearing; higher deflection under load. | Standard replacements where OEM ride comfort is the priority. |

| Polyurethane (Performance) | Denser, more rigid compound, often available in various hardnesses. | Far superior abrasion and tear resistance; maintains shape better; longer life; less deflection. | Can transmit more high-frequency vibration (firmer ride); requires proper lubrication during install. | Performance, off-road, and heavy-load applications where durability and precise handling trump softness. |

| Bronze (Heavy-Duty/Self-Lubricating) | A metallic alloy, often with graphite or oil plugs embedded. | Extremely high load capacity; handles high temperatures; wear-resistant; often maintenance-free. | Minimal inherent vibration damping (can be noisy); typically higher cost; requires precise installation. | Extreme-duty, high-mileage, and industrial applications (mining, logging, severe service) where failure is not an option. |

The trend in demanding industries is moving away from standard rubber due to its limited service life under stress. The quest is for a solution that combines longevity, high load capacity, and consistent performance—a need that leads us to advanced metallic solutions.

MYWAY Bimetal Bushings: The Engineered Solution for Uncompromising Demands

At MYWAY, we specialize in solving the toughest friction and wear challenges. Our Bimetal Leaf Spring Bushings are engineered from the ground up for applications where standard components fail. We understand that for your fleet or equipment, downtime is the greatest cost.

Our bushings are not simply bronze; they are a high-performance bimetal system. We fuse a strong, wear-resistant outer shell (often a high-tensile brass or bronze alloy like CuZn25Al6Fe3Mn3) with a uniquely engineered inner lining of solid lubricants, such as graphite.

This architecture delivers decisive advantages:

Unmatched Durability & Load Capacity: The metallic structure provides exceptional yield strength, resisting deformation under extreme vertical and horizontal loads. It handles the high stress concentrations at the spring eye that can crush softer materials.

True Maintenance-Free Operation: The embedded solid lubricants create a permanent, low-friction film on the wear surface. This eliminates the need for periodic greasing—a significant maintenance saving—and prevents the dry, squeaky operation common with worn rubber or unlubricated metal.

Consistent Performance in Harsh Environments: Unlike rubber, our bimetal bushings are impervious to degradation from oil, grease, ozone, or temperature extremes (stable well beyond 150°C). They perform identically in the freezing cold, desert heat, or wet, muddy conditions.

Precision and Stability: With minimal compression set and clearance growth over time, MYWAY bushings help maintain precise axle alignment for longer periods. This leads to more predictable handling and reduced wear on adjacent components like tires and U-bolts.

Ready for a Bushing That Works as Hard as You Do?

Don’t let a small, inexpensive component like a bushing become the weak link that causes major downtime, safety concerns, and rising maintenance costs. Upgrading to engineered MYWAY Bimetal Bushings is an investment in the reliability and longevity of your equipment.

Contact MYWAY today for a consultation. Our engineering team is ready to help you select the perfect bushing solution or develop a custom design for your unique challenge. Request a quote and let us show you how the right pivot point can make all the difference.

FAQ: Leaf Spring Bushings Demystified

Q: How do I know my leaf spring bushings need replacing?

A: Common signs include: a pronounced clunking or banging sound over bumps (especially when laden), visible cracking, tearing, or disintegration of the rubber, excessive movement or “slop” between the spring eye and the bolt, and uneven or accelerated wear on your tires.

Q: Can I install new bushings myself?

A: Yes, with the right tools (press, saw, torch, etc.) and mechanical skill. The process involves removing the spring, extracting the old bushing (often the hardest part, requiring burning or cutting), and pressing the new one in with proper alignment. However, due to the significant forces and safety-critical nature of the suspension, professional installation is highly recommended for most users.

Q: Are polyurethane bushings always better than rubber?

A: Not always. Polyurethane excels in durability and load handling but provides a firmer ride. If your primary goal is to restore the original, vibration-absorbing comfort of a light-duty truck or RV, high-quality rubber OEM replacements may be the better choice. For heavy loads, towing, or performance, polyurethane or metallic bushings are superior.

Q: Why choose a metallic/bronze bushing over polyurethane?

A: Choose metallic when you operate in the most severe conditions: extreme gross vehicle weights, constant high mileage (e.g., long-haul trucking), exposure to high temperatures (near brakes/exhaust), or in industries like mining and construction where absolute component reliability is paramount to avoid catastrophic downtime.

Q: My application is unique. Can you provide custom bushings?

A: Absolutely. At MYWAY, custom engineering is our specialty. We can tailor the bimetal material composition, dimensions, wall thickness, graphite plug configuration, and lubrication channels to meet your specific load, motion, and environmental requirements. Send us your specs or a failed sample for analysis.