MYWAY: Comprehensive Product List for Truck Rocker Arm Bushings in China

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

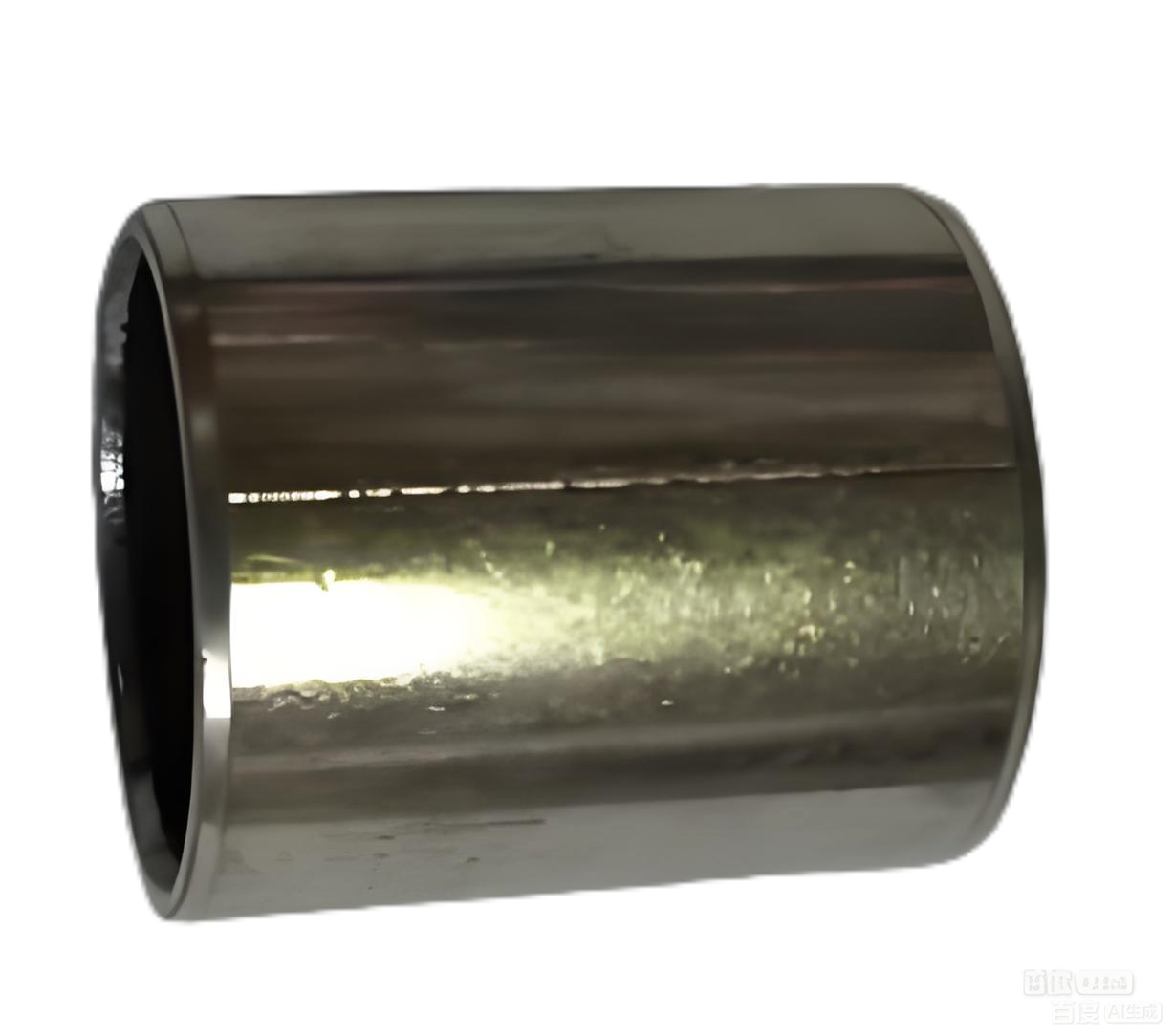

MYWAY Truck Rocker Arm bushing

ROCKER ARM BUSHING, EXHAUST (5410550550 - 5410550650) - TRUCK PARTS

FITS MODEL ACTROS, ACTROS MP2 MP3, AXOR, AXOR 2, CAPACITY (O 530 GL), CITARO (O 530), CONECTO (O 345), INTEGRO (O 550), O 403, TOURISMO (O 350), TOURO (O 500), TRAVEGO (O 580) COMPATABILITY ENGINE/MERCEDESBENZ/OM 457915 DIESEL EURO 3 (D3), ENGINE/MERCEDESBENZ/OM 457916 DIESEL EURO 3 (D3), ENGINE/MERCEDESBENZ/OM 457917 DIESEL EURO2EURO3,

ROCKER ARM BUSHING (3460550250)

PRIMARY DIVISION TRUCK PART NUMBER'S 3460550250

ACCESSORIES ROCKER ARM Archives - TRUCK PARTS

PRIMARY DIVISION TRUCK PART NUMBER'S 99434732

Rocker Arm Bushing

Rocker Arm Bushing 11 33 1 252 628 11331252628

Rocker Arm bushing

Product Code: 24564d Fits F12 , F14 ,A , AV , B , BN ,C , SUPER C

Cummins Injector Rocker Arm Bushing 207226 for all KT series engines

Series KT series Type Rocker arm bush Compatible Models KT19, KT38, KT50 Manufacturer Part Number 207226,205147 Business & Industrial Heavy Equipment, Parts & Attachments

Rocker Arm Bushing, 1750065M1

Specifications Sold individually 8 used per rocker arm 1.006" length 0.813" outside diameter 0.620" inside diameter Must ream to size after installed

Rocker Arm Bushing

OEMNo.:1850018M1/1021910014/21910014/S.40284

ROCKER ARM BUSH (5410550750)

PRIMARY DIVISION TRUCK FITS MAKE MERCEDES BENZ FITS MODEL ACTROS, AXOR, CAPACITY, CITARO, CONECTO, INTEGRO, SERIE 400, TOURISMO, TOURO, TRAVEGO COMPATABILITY TRUCK/EVOBUS/CAPACITY, TRUCK/EVOBUS/CITARO, TRUCK/EVOBUS/CONECTO, TRUCK/EVOBUS/INTEGRO, TRUCK/EVOBUS/TOURISMO, TRUCK/EVOBUS/TOURO

Bronze Rocker Arm Bushings

Bronze Bushings. Fits all Blue Ultra-Lites

BUSHING, rocker arm

Product Name: BUSHING, rocker arm Make: MG Model: MGC Series: RD, GT Year: 1968, 1969

ROCKER ARM BUSHING

These bushings are solid billet bearing bronze bar stock to repair roller rockers that use Torrington Roller Bearings. Also works in Crane and S&S Rocker Arms with approximately .785" inside diameter

Rocker Arm Bush

Rocker Arm Bush ID: 31.5mm Engine Model Barcode 128 S.40284 Barcode EAN13 5023495402840 Inner Ø (mm) 31.5 Length (mm) 28.5 Outer Ø (mm) 35 Related products 19175 135, 135 GAS / 135 PETROL, 145, 148, 155, 158, 165, 168, 175, 178, 185, 188, 20B, 20D, 20E, 230, 230 US BUILT, 231, 235, 240, 245, 250, 30E, 35, 35 GAS / 35 PETROL, 35X, 40, 65, 765

Rocker Arm Bushing

ROCKER ARM Archives - TRUCK PARTS

York Rocker Bush for all trailer parts and truck Parts

10000+ Types of Truck Rocker Arm Bushing – Contact Us for Details

| Component Category | Specific Type / Model | Product Series Name |

| Truck, Rocker Arm | Rocker Arm | Steel Bushing |

Rocker Arm Bushing Failure: The Hidden Engine Killer and How MYWAY Solves It

For fleet managers and diesel technicians, few sounds are more unsettling than a persistent, metallic ticking or tapping coming from a truck’s valve cover. This noise is more than an annoyance; it’s often the first cry for help from a failing rocker arm bushing. As a critical yet frequently overlooked component in the valvetrain system, a worn bushing doesn’t just create noise—it can trigger a cascade of engine damage, leading to costly downtime and repairs. This article delves into the root causes of rocker arm bushing failure, explores why it’s a prevalent issue in heavy-duty applications, and introduces how MYWAY’s engineered bushing solutions provide the durability and performance your fleet demands.

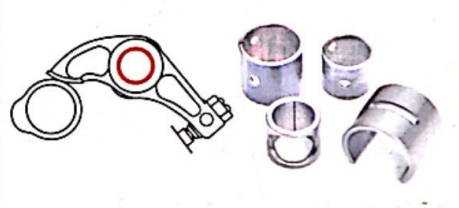

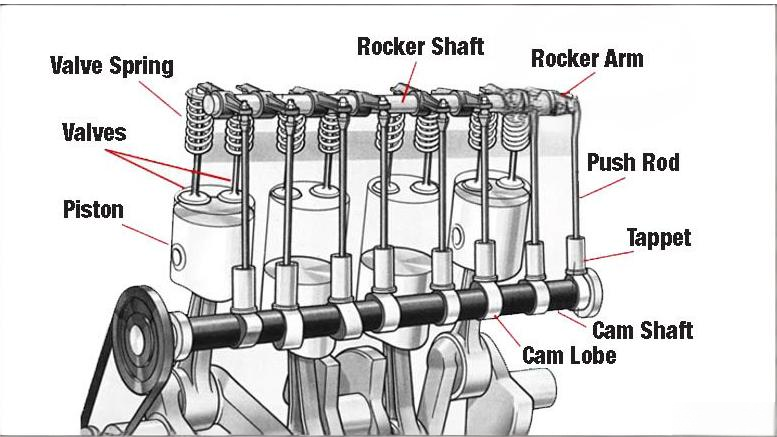

The Critical Role and Common Failure of Rocker Arm Bushings

The rocker arm is a pivotal lever in an engine’s valve train. It converts the upward motion of the pushrod (in a pushrod engine) or the direct cam lobe lift into a downward force to open the engine valves. The rocker arm pivots on a shaft, and this pivotal point is supported by the rocker arm bushing.

This bushing is a plain bearing that must withstand extreme conditions:

High Loads: It bears significant force from valve springs and camshaft action.

High-Speed Oscillation: It pivots thousands of times per minute.

Marginal Lubrication: It often operates in a starved lubrication environment, relying on oil splash or limited feed holes.

A failure here manifests clearly:

Audible Ticking/Tapping: The classic symptom of excessive clearance due to wear.

Metal Debris in Oil: Worn bushing material (often copper or bronze) contaminates the oil system.

Reduced Engine Performance: Lost motion leads to poor valve timing, causing power loss and misfires.

Catastrophic Engine Damage: In severe cases, a seized bushing can break a rocker arm, dropping a valve into the cylinder.

The provided forum post from a frustrated vehicle owner is a textbook case: after extensive troubleshooting for a misfire, they discovered all 32 rocker arm bushings were “completely destroyed” with visible grooves worn into them, despite proper initial lubrication and maintenance. This highlights that the problem often lies deeper than simple neglect.

The Root Causes: Why Do Rocker Arm Bushings Fail?

Understanding why bushings fail is key to finding a superior solution. Research and field experience point to several interconnected factors:

Uneven Pressure Distribution (The Primary Culprit): A 2023 elasto-hydrodynamic lubrication (EHL) analysis of a diesel engine rocker arm bushing revealed that uneven pressure distribution across the bushing surface is a leading cause of accelerated wear. When load is concentrated on a small area, the oil film breaks down, leading to metal-to-metal contact.

Oil Starvation and Quality: The rocker arm assembly can be far from the main oil gallery. During cold starts, frequent idling (common in dump trucks or cement mixers), or with degraded oil, the bushing may not receive adequate lubrication. The forum user speculated if “idling time” was killing their bushings, which aligns with this risk.

Material and Design Limitations: Conventional bronze or powdered metal bushings may lack the wear resistance and embedability (ability to trap debris) needed for modern, high-output diesel engines. Furthermore, a narrow bushing width increases specific load, exacerbating the pressure distribution problem. The study found that increasing bushing width significantly improved pressure distribution and reduced maximum wear by over 70%.

The “Band-Aid” Rebuild Cycle: The market offers many rebuild kits. However, simply replacing a destroyed bushing with one of the same design and material quality guarantees a repeat failure. As one mechanic working on a high-mileage motorcycle noted, he was forced to “try and make my own bushings” after identifying rapid wear, underscoring the lack of reliable OEM-spec or better replacements.

The table below summarizes the problem-solution dynamic:

| Problem | Conventional Outcome | MYWAY’s Engineered Solution |

|---|---|---|

| Uneven Load Distribution | Localized wear, grooving, and early failure. | Advanced design and material science to ensure even load bearing. |

| Marginal Lubrication | Rapid wear during cold starts or idling, metal contamination. | High-performance bearing materials that maintain integrity under oil-starved conditions. |

| Material Fatigue | Bushings deform, lose clearance, and seize under high temps/loads. | Premium alloy compositions for superior heat resistance and structural stability. |

| Standard Replacement Parts | Identical specs to the failed part, repeating the failure cycle. | Redesigned, application-specific solutions that address the root cause, not just the symptom. |

The MYWAY Advantage: Engineered for Endurance, Built for Demand

At MYWAY, we don’t just manufacture bushings; we engineer solutions for the most demanding heavy-duty commercial applications. Our approach is rooted in the same holistic design principles used by leading industry innovators to optimize components for strength, durability, and NVH (Noise, Vibration, Harshness).

Our technical differentiators include:

Advanced Material Science: We utilize proprietary high-strength bronze alloys and composite materials. These are engineered for exceptional wear resistance, low friction coefficients, and excellent conformability to ensure optimal oil film retention, directly addressing the EHL challenges identified in research.

Precision Engineering for Perfect Fit: Like the ISO 9001:2015 certified manufacturing referenced in high-quality aftermarket parts, our process ensures micron-level precision. This guarantees perfect interference fit on the rocker shaft and correct clearance, eliminating the sloppy play that causes noise and wear.

Design Optimization: We analyze specific engine models to optimize bushing parameters like width, wall thickness, and oil groove geometry. This ensures even pressure distribution and maximizes lubrication efficiency, translating directly to longer service life.

Rigorous Validation: Every MYWAY bushing batch undergoes stringent quality and performance testing to meet or exceed OEM specifications, ensuring reliability you can count on for the long haul.

For fleet managers, this means extended maintenance intervals, reduced risk of catastrophic engine failure, and lower total cost of ownership. For distributors and wholesalers, it means offering a premium, problem-solving product that builds customer loyalty and reduces comebacks.

Conclusion: Don’t Just Replace, Upgrade

The repetitive failure of rocker arm bushings is not an unavoidable cost of business. It is a solvable engineering challenge. By moving beyond standard replacement parts to performance-engineered solutions, you can break the cycle of downtime and repair.

MYWAY is committed to providing that upgrade path. We invite engineering procurement managers, heavy-duty parts wholesalers, and fleet maintenance directors to experience the difference that a thoughtfully designed and robustly manufactured component can make.

Ready to specify the superior solution? Contact MYWAY today to request technical data sheets, discuss your specific application requirements, or to request a quote for your next project. Let’s build reliability together.

FAQ: Truck Rocker Arm Bushings

Q1: What are the most common signs of a worn rocker arm bushing?

The most obvious sign is a distinct ticking or tapping noise from the valve cover area that changes with engine speed. You may also find metallic particles (often brass or copper-colored) in your engine oil or on the magnetic drain plug. Loss of engine power and misfires can also be related to excessive valvetrain play from worn bushings.

Q2: Why did my new bushings fail again so quickly?

Premature repeat failure often points to an underlying issue not addressed during replacement. This includes:

Poor lubrication: A clogged oil passage to the rocker shaft.

Misaligned or worn rocker shaft: This creates an uneven load on the new bushing.

Inferior quality replacement part: Many aftermarket bushings use substandard materials or imprecise dimensions. Installing a bushing with the same specs as the one that failed sets you up for the same outcome.

Q3: Can I just replace the bushings, or do I need new rocker arms?

It depends on the condition of the rocker arm itself. If the arm’s bushing bore is scored, elongated, or damaged, installing a new bushing will not restore proper fit. In such cases, a new rocker arm or a quality remanufactured arm with a pre-installed, high-spec bushing (like those from MYWAY) is the more reliable choice.

Q4: Are roller rocker arms a better solution than bushed arms?

Roller rockers, which use a needle bearing at the pivot point, offer significantly reduced friction and can handle higher lift camshafts. They are an excellent performance upgrade. However, for standard OEM replacement in heavy-duty trucks, a high-quality bushed arm (when properly designed and lubricated) remains a cost-effective and extremely durable solution. The choice depends on your performance needs and budget.

Q5: How can I ensure my new rocker arm bushings last?

Clean Thoroughly: Before installation, ensure all oil galleries in the cylinder head and rocker shaft are completely clear of debris.

Prime the System: Pre-lube the bushings and shaft with assembly grease or engine oil. After assembly, crank the engine (with fuel disabled) until oil pressure builds.

Use Quality Oil: Maintain your engine with the correct grade and specification of oil, and change it at recommended intervals to prevent abrasive wear from contamination.

Choose Quality Parts: Invest in bushings from a reputable manufacturer like MYWAY that focuses on material quality and precise engineering, not just meeting basic dimensions.