Home » Wear Plate / Slide Block

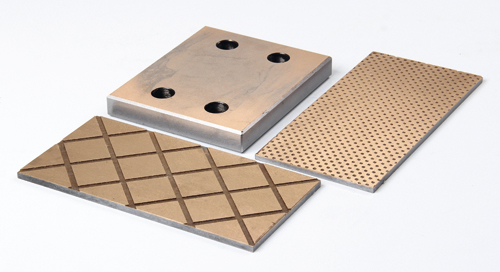

MYWAY Wear Plate / Slide Block Product List

What is Wear Plate / Slide Block?

A Wear Plate (or Wear Strip) is a sacrificial, protective component installed on surfaces subjected to abrasion, impact, or erosion. Its primary function is to absorb damage and extend the service life of more expensive underlying machinery or structures. Characterized by its high hardness and material durability, it is a fundamental and cost-effective solution for preserving equipment in harsh environments like mining, material handling, and heavy machinery.

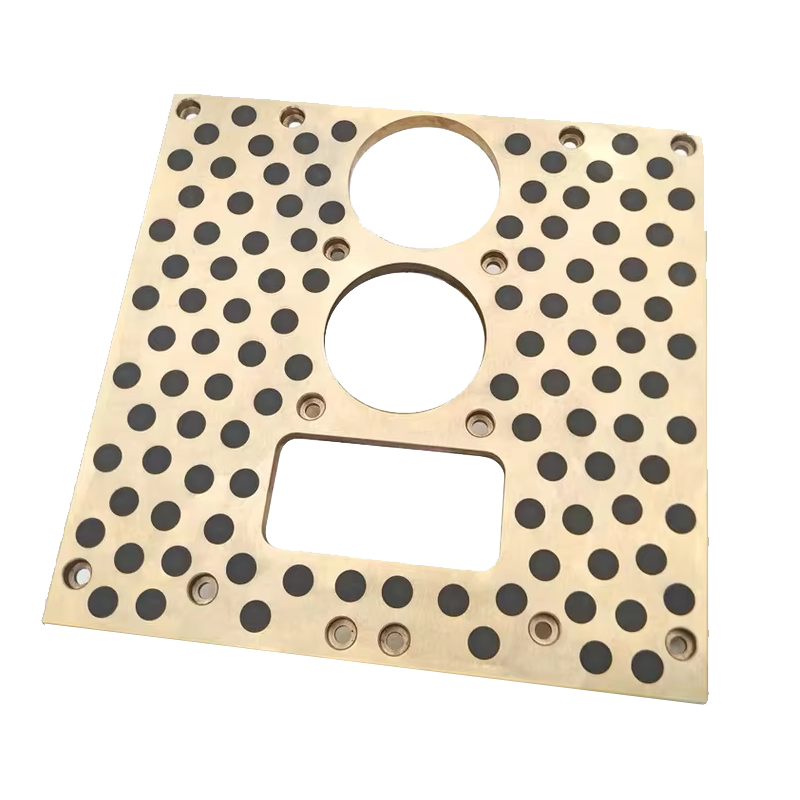

A Slide Block (or Slide Plate/Bearing) is a low-friction, linear motion component designed to facilitate controlled movement between two surfaces. It serves as a critical interface that accommodates thermal expansion, contraction, or structural shifting while supporting significant loads. Characterized by its self-lubricating properties and maintenance-free operation, it is an essential mechanical element for ensuring safety, reducing stress, and preventing damage in applications ranging from bridge supports and pipeline systems to industrial presses and construction equipment.

Based on the differences in material composition—from hardened steel and bronze alloys to advanced graphite-embedded composites—and the specific application requirements, we offer a comprehensive series of wear plates and slide blocks in standard specifications. Additionally, we possess the engineering capability to develop and design customized, non-standard solutions tailored to the unique purposes, operating conditions, and performance criteria provided by our customers. Should you have any project needs or technical inquiries, please feel free to contact us at any time.

Silent Guardians: The Complete Guide to Wear Plates and Slide Blocks

For engineers and procurement specialists in heavy industry, few things are as critical—or as costly to neglect—as the components that manage friction, wear, and movement. At the heart of countless mechanical and structural systems lie two fundamental elements: the Wear Plate and the Slide Block (or Slide Plate). While they often work in tandem, their roles are distinct, and choosing the right one can mean the difference between seamless operation and costly downtime.

This guide cuts through the complexity. We’ll define these components, explore their materials and applications, and introduce you to a superior engineered solution designed for the most demanding environments.

Defining the Duo: Protection vs. Movement

Think of a Wear Plate as armor. Its primary function is sacrificial protection. It is a plate installed on a surface subjected to continuous abrasion, impact, or erosion. By being harder and more wear-resistant than the base material it protects, it absorbs the damage, dramatically extending the service life of expensive machinery. Common in mining, cement, and material handling, they are the frontline defense against degradation.

A Slide Plate or Slide Block, on the other hand, is a facilitator of movement. Classified as a type of linear bearing, it is engineered to allow controlled, low-friction sliding between two surfaces. Imagine a bridge expanding in the heat, a pipeline contracting in the cold, or a massive pressure vessel settling. These plates accommodate that movement, preventing harmful stresses from building up in the structure. They are the unsung heroes ensuring thermal expansion doesn’t lead to catastrophic failure.

The Material Science: Choosing the Right Shield or Bearing

The performance of both wear plates and slide plates is dictated by their material composition. The choice hinges on the specific demands of load, speed, temperature, and environmental conditions.

Common Materials for Wear Plates:

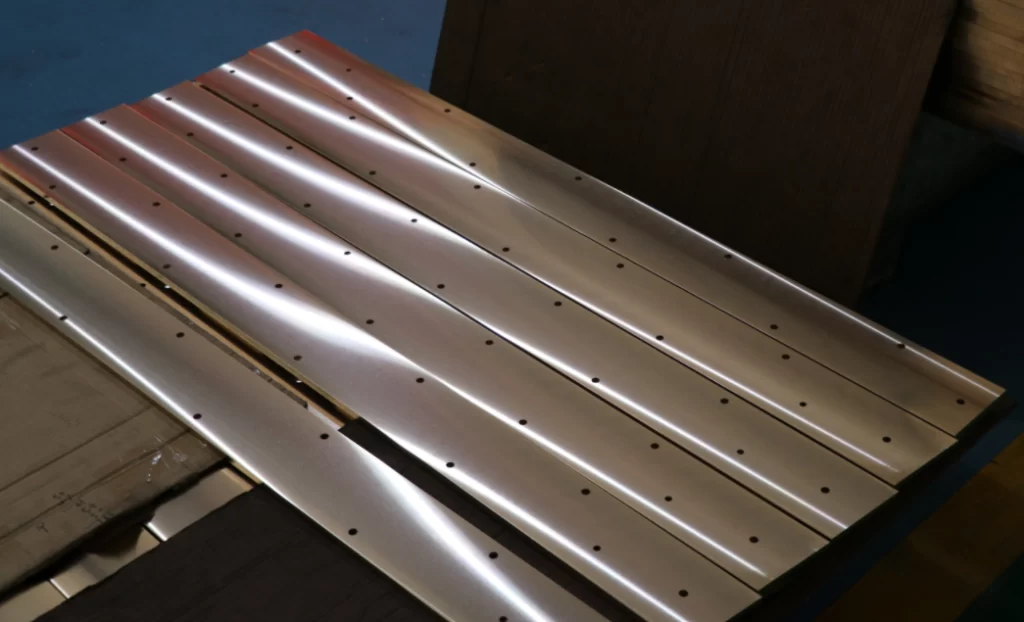

Hardened Steel & Alloy Plate: Often called Wear Resistant Steel Plate, these are workhorses made from low-carbon steel or low-alloy steel with a surface layer hardened to high levels (typically HRC 58-62). They offer excellent abrasion resistance for applications like truck liners, chutes, and hoppers.

Ceramic-Composite Plates: For extreme abrasion, plates embedded with ceramic tiles provide a hardness far surpassing steel, ideal for high-wear zones in mining and power generation.

Common Materials for Slide Plates/Blocks:

The goal here is a low coefficient of friction, often combined with self-lubricating properties. A comparison of common bearing materials highlights the trade-offs:

| Material Type | Key Advantages | Key Limitations | Ideal Application |

|---|---|---|---|

| Pure Metal | High strength, high conductivity, low cost | Poor lubrication, can cause wear to mating surface | General purpose, low-speed, high-strength needs |

| Bronze/Copper Alloy | Good strength, wear resistance, machinability | Often requires external lubrication | Bushings, general industrial bearings |

| Bronze with Solid Lubricant | Self-lubricating, good wear resistance, handles higher loads | Can be more costly than pure metal | Maintenance-free applications, dirty environments |

| PTFE-Based | Extremely low friction, chemical resistant | Lower load capacity, can creep under pressure | Precision movement, corrosion-prone areas |

As the table shows, bronze-based materials embedded with solid lubricants like graphite offer a compelling balance. They provide the strength of metal while the graphite creates a dry lubricating film, enabling maintenance-free operation—a critical feature in enclosed or hard-to-reach machinery.

Where They Work: Industries Built on Reliability

These components are ubiquitous across heavy industry. Your project likely needs them if it involves:

Heavy Machinery & Construction: In excavators, presses, and mill guides, wear plates protect structural frames, while slide blocks facilitate movement in hydraulic cylinders and boom arms.

Material Handling & Processing: Conveyor systems, sorting plants, and bulk handlers rely on wear plates to line surfaces. Slide plates are essential under storage silos and hoppers that shift with filling and emptying.

Energy & Infrastructure: In bridges and large pipelines, slide plates are critical at expansion joints and supports. In power plants, they manage thermal movement in ducts and boiler systems.

The MYWAY Advantage: Engineered for Endurance

Understanding the theory is one thing; sourcing a reliable, high-performance component is another. This is where MYWAY Bushings and engineered slide solutions stand out.

We go beyond standard offerings to provide solid lubricating bearings and plates designed for the real-world challenges of mining equipment, construction machinery, and metallurgical plants.

Why Specify MYWAY?

Our products, like our heavy-duty spherical plain bearings, are engineered with a clear purpose:

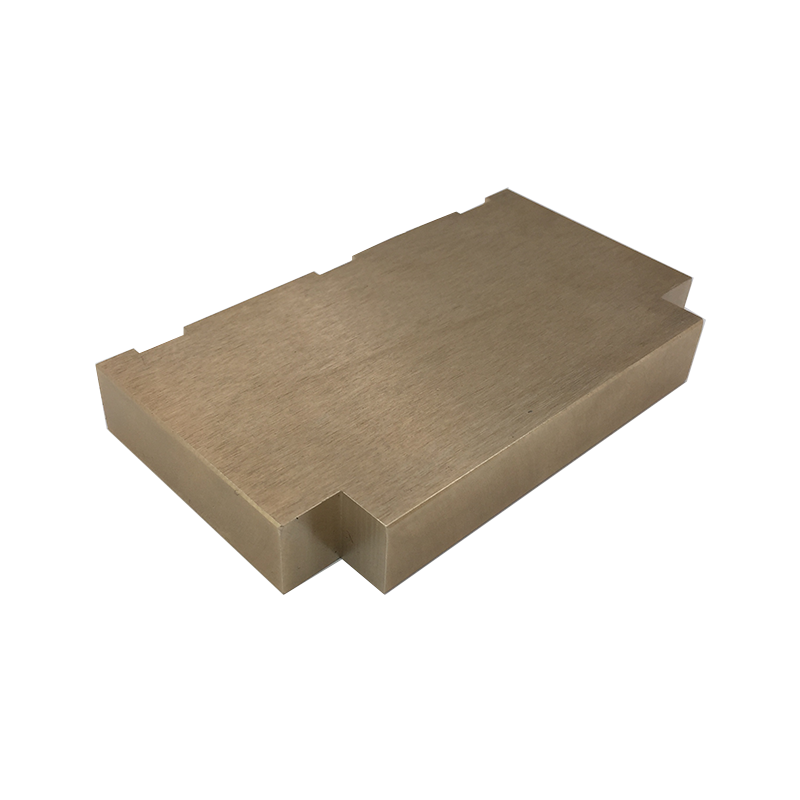

Superior Material Science: We use high-performance copper-zinc alloys like CuZn25A16Fe3Mn3 as a base. This isn’t just standard bronze; it’s a formulation designed for high mechanical strength and excellent load distribution.

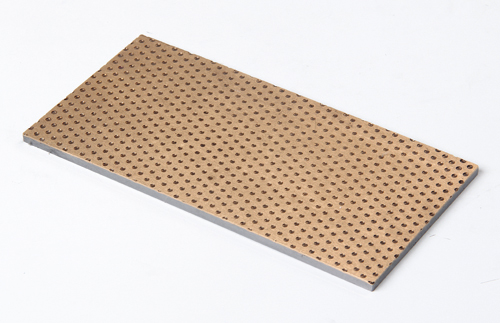

Integrated Self-Lubrication: Engineered graphite plugs are embedded into the alloy matrix. During operation, a thin, protective lubricating film is transferred to the mating surface. This results in a consistently low friction coefficient (µ between 0.04–0.16) and truly maintenance-free operation, even in dusty or wet conditions where oil lubrication would fail.

Built for Demanding Duty: With an ultimate dynamic load capacity of 100 N/mm² and the ability to withstand temperatures up to 300°C, our components are built for the harsh realities of heavy industry.

Precision and Reliability: We employ automated production lines and stringent quality control, ensuring high dimensional accuracy and consistent performance in every batch.

Frequently Asked Questions (FAQ)

Q1: What’s the main difference between a wear plate and a slide plate?

A wear plate is primarily for protection against abrasion and is typically fixed in place. A slide plate is a linear bearing designed to enable and guide movement between two surfaces, with a focus on minimizing friction.

Q2: When should I choose a self-lubricating bronze slide block over a PTFE one?

Choose self-lubricating bronze for applications with higher load requirements, impact risk, or where you need a completely maintenance-free solution in harsh environments (dust, grime). PTFE is excellent for very low friction and corrosive settings but may have lower load-bearing capacity.

Q3: My application involves slow movement under very high load. What should I look for?

This is a classic scenario for maintenance-free slide blocks or bushings. Focus on specifications like ultimate dynamic load (e.g., 100 N/mm²) and ensure the product is rated for high-load, low-speed applications. A material with a solid lubricant like graphite is essential to prevent seizure.

Q4: Can these components be customized?

Yes. Reputable manufacturers like MYWAY offer extensive customization. This includes custom dimensions, thicknesses, specific hole patterns, graphite plug configurations, and adaptations for unique environmental challenges like extreme heat or chemical exposure.

Q5: How do I ensure a long service life for my slide plates?

The key is proper selection from the start. Match the material to your load, speed, and temperature. Ensure correct installation with proper alignment. For self-lubricating types, no maintenance is needed, but keeping the sliding area free from excessive abrasive contaminants will maximize lifespan.

Conclusion: The Foundation of Reliable Design

Wear plates and slide blocks are not mere commodities; they are foundational engineering elements that ensure safety, longevity, and efficiency. Specifying the right component—one with the appropriate material, lubrication, and load rating—is a direct investment in reducing downtime and total cost of ownership.

For engineers who cannot afford compromise, the solution lies in precision-engineered products. MYWAY Bushing represents this philosophy: combining advanced metallurgy with integrated solid lubrication to deliver reliability where it matters most.

Ready to specify components that won’t let you down? Contact us today to discuss your specific application requirements or to request technical datasheets for our MYWAY self-lubricating bearing and slide plate solutions. Let our engineering be the foundation of your reliability.