High-Performance, Wear-Resistant Wrapped Bronze Bushings

MYWAY: Expert Bushing Manufacturer in China with 20 Years of Experience.

We deliver custom & standard parts from casting to finish, IATF/ISO certified for 40+ countries.

Cost-effective solutions with reliable logistics.

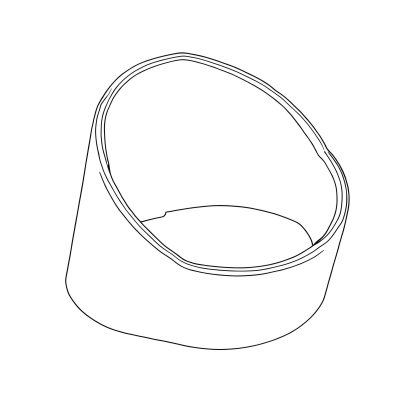

Home » Wrapped Bronze Bushing_

Wrapped Bronze Bushing

What is Wrapped Bronze Bushing?

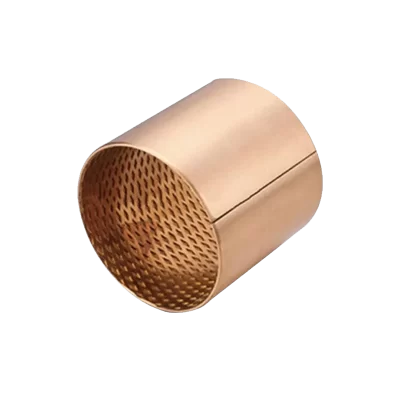

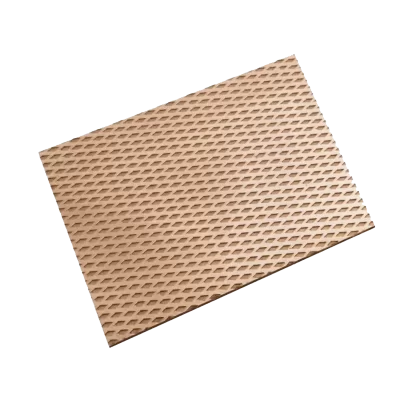

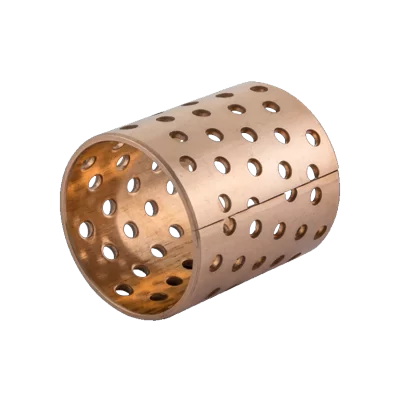

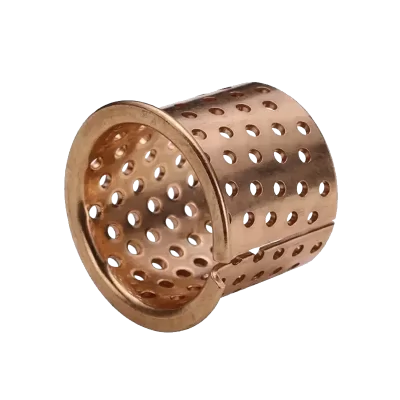

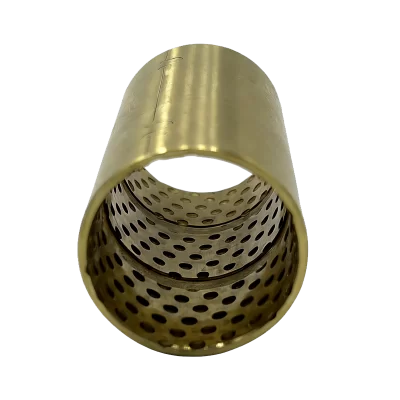

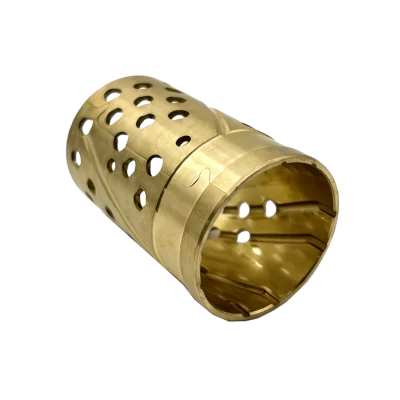

Wrapped bronze bearings are manufactured from high-density copper alloy (CuSn8P) and can be customized with surface patterns such as diamond or hemispherical oil pockets, lubrication grooves, or uniformly distributed lubrication holes. After assembly and lubrication, these bearings facilitate rapid oil film formation during initial operation, reducing starting friction coefficient. They offer high density, exceptional load capacity, excellent wear resistance, and extended service life, serving as compact and cost-effective replacements for traditional cast bronze bushings. Widely used in agricultural, forestry, engineering, and construction machinery.

Wrapped Bronze Bushings by Structure

Wrapped Bronze Bushings by Material

MW090 Series

MW092 Series

MW091 Series

Wrapped Bronze Bushings by Feature

Wrapped Bronze Bushings by Type

Which Specification Do You Need?

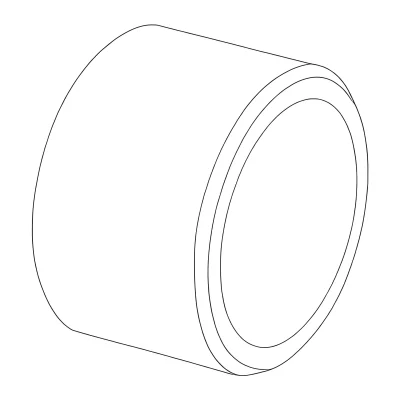

Plain Bushing

| Type | Spec | Type | Spec | Type | Spec | Type | Spec | Type | Spec | Type | Spec |

| 1010 | 12×10×10 | 1310 | 15×13×10 | 1615 | 18×16×15 | 2010 | 23×20×10 | 2410 | 27×24×10 | 2532 | 28×25×32 |

| 1012 | 12×10×12 | 1312 | 15×13×12 | 1618 | 18×16×18 | 2012 | 23×20×12 | 2412 | 27×24×12 | 2535 | 28×25×35 |

| 1015 | 12×10×15 | 1315 | 15×13×15 | 1620 | 18×16×20 | 2015 | 23×20×15 | 2415 | 27×24×15 | 2540 | 28×25×40 |

| 1020 | 12×10×20 | 1410 | 16×14×10 | 1625 | 18×16×25 | 2020 | 23×20×20 | 2420 | 27×24×20 | 2550 | 28×25×50 |

| 1108 | 13×11×8 | 1412 | 16×14×12 | 1708 | 19×17×8 | 2025 | 23×20×25 | 2425 | 27×24×25 | 2560 | 28×25×60 |

| 1109 | 13×11×9 | 1415 | 16×14×15 | 1710 | 19×17×10 | 2030 | 23×20×30 | 2428 | 27×24×28 | 2610 | 30×26×10 |

| 1110 | 13×11×10 | 1420 | 16×14×20 | 1712 | 19×17×12 | 2035 | 23×20×35 | 2430 | 27×24×30 | 2612 | 30×26×12 |

| 1112 | 13×11×12 | 1422 | 16×14×22 | 1715 | 19×17×15 | 2040 | 23×20×40 | 2432 | 27×24×32 | 2615 | 30×26×15 |

| 1206 | 14×12×6 | 1425 | 16×14×25 | 1718 | 19×17×18 | 2210 | 25×22×10 | 2435 | 27×24×35 | 2620 | 30×26×20 |

| 1208 | 14×12×8 | 1508 | 17×15×8 | 1720 | 19×17×20 | 2212 | 25×22×12 | 2438 | 27×24×38 | 2625 | 30×26×25 |

| 1210 | 14×12×10 | 1510 | 17×15×10 | 1725 | 19×17×25 | 2215 | 25×22×15 | 2440 | 27×24×40 | 2630 | 30×26×30 |

| 1212 | 14×12×12 | 1512 | 17×15×12 | 1808 | 20×18×8 | 2220 | 25×22×20 | 2450 | 27×24×50 | 2635 | 30×26×35 |

| 1214 | 14×12×14 | 1515 | 17×15×15 | 1810 | 20×18×10 | 2225 | 25×22×25 | 2510 | 28×25×10 | 2640 | 30×26×40 |

| 1215 | 14×12×15 | 1518 | 17×15×18 | 1812 | 20×18×12 | 2230 | 25×22×30 | 2512 | 28×25×12 | 2650 | 30×26×50 |

| 1216 | 14×12×16 | 1520 | 17×15×20 | 1815 | 20×18×15 | 2235 | 25×22×35 | 2515 | 28×25×15 | 2810 | 32×28×10 |

| 1220 | 14×12×20 | 1525 | 17×15×25 | 1820 | 20×18×20 | 2238 | 25×22×38 | 2520 | 28×25×20 | 2812 | 32×28×12 |

| 1225 | 14×12×25 | 1608 | 18×16×8 | 1825 | 20×18×25 | 2240 | 25×22×40 | 2525 | 28×25×25 | 2815 | 32×28×15 |

| 1308 | 15×13×8 | 1610 | 18×16×10 | 1830 | 20×18×30 | 2245 | 25×22×45 | 2528 | 28×25×28 | 2820 | 32×28×20 |

| 1309 | 15×13×9 | 1612 | 18×16×12 | 2008 | 23×20×8 | 2250 | 25×22×50 | 2530 | 28×25×30 | …… | …… |

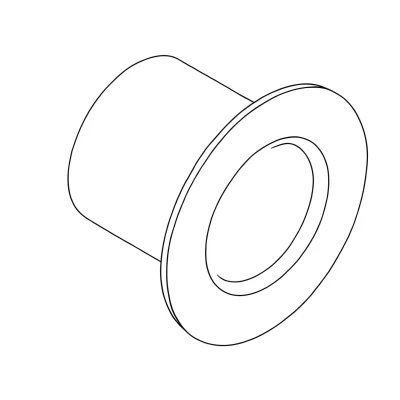

Flange Bushing

| Type | Spec. | Type | Spec. | Type | Spec. | Type | Spec. |

| 2515 | 25×28/35×15 | 11050 | 110×115/130×50 | 6030 | 60×65/75×30 | 18090 | 180×185/215×90 |

| 2525 | 25×28/35×25 | 11090 | 110×115/130×90 | 6035 | 60×65/75×35 | 19060 | 190×195/225×60 |

| 3020 | 30×34/45×20 | 12050 | 120×125/140×50 | 6060 | 60×65/75×60 | 19090 | 190×195/225×90 |

| 3030 | 30×34/45×30 | 12090 | 120×125/140×90 | 6530 | 65×70/80×30 | 20060 | 200×205/235×60 |

| 3520 | 35×39/50×20 | 13060 | 130×135/155×60 | 6560 | 65×70/80×60 | 20090 | 200×205/235×90 |

| 3530 | 35×39/50×30 | 13090 | 130×135/155×90 | 7040 | 70×75/85×40 | 22560 | 225×230/260×60 |

| 4025 | 40×44/55×25 | 14060 | 140×145/165×60 | 7070 | 70×75/85×70 | 22590 | 225×230/260×90 |

| 4040 | 40×44/55×40 | 14090 | 140×145/165×90 | 7540 | 75×80/90×40 | 25060 | 250×255/290×60 |

| 4530 | 45×50/60×30 | 15060 | 150×155/180×60 | 7570 | 75×80/90×70 | 25090 | 250×255/290×90 |

| 4545 | 45×50/60×45 | 15090 | 150×155/180×90 | 8040 | 80×85/100×40 | 26060 | 265×270/305×60 |

| 4550 | 45×50/60×50 | 16060 | 160×165/190×60 | 8080 | 80×85/100×80 | 26090 | 265×270/305×90 |

| 5030 | 50×55/65×30 | 16090 | 160×165/190×90 | 9050 | 90×95/110×50 | 28560 | 285×290/325×60 |

| 5050 | 50×55/65×50 | 17060 | 170×175/200×60 | 9090 | 90×95/110×90 | 28590 | 285×290/325×90 |

| 5530 | 55×60/70×30 | 17090 | 170×175/200×90 | 10050 | 100×105/120×50 | 30050 | 300×305/340×60 |

| 5550 | 55×60/70×50 | 18060 | 180×185/215×60 | 10090 | 100×105/120×90 | 30090 | 300×305/340×90 |

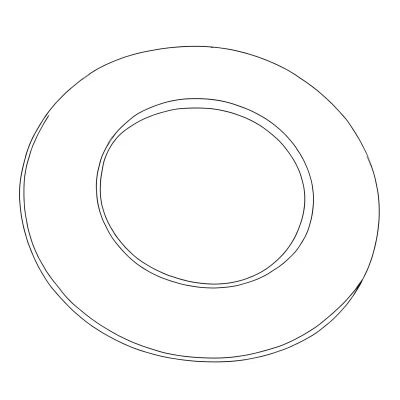

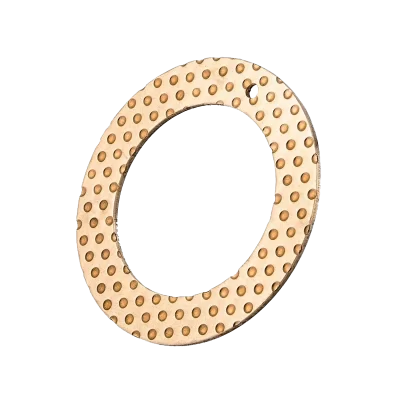

Thrust Washer

| Type | Spec | Type | Spec |

| DP10 | 20×10×1.5 | DP26 | 44×26×1.5 |

| DP12 | 24×12×1.5 | DP28 | 48×28×1.5 |

| DP14 | 26×14×1.5 | DP32 | 54×32×1.5 |

| DP16 | 30×16×1.5 | DP36 | 62×38×1.5 |

| DP18 | 32×18×1.5 | DP42 | 66×42×1.5 |

| DP20 | 36×20×1.5 | DP48 | 74×48×2 |

| DP22 | 38×22×1.5 | DP52 | 78×52×2 |

| DP24 | 42×24×1.5 | DP62 | 90×62×2 |

Key Considerations:

- Size Suitability: When selecting sizes, ensure that the chosen dimensions are appropriate for your specific applications and assembly space. Different machinery might require specific inner diameters, outer diameters, and lengths.

- Customization Services: We offer customization services, allowing the production of bushings with special dimensions tailored to your specific requirements.

- Inquiry and Procurement: Before making a purchase, it is advisable to contact multiple suppliers to compare prices and delivery times, selecting the optimal supply solution.

I hope this expanded size list helps you find the suitable bushing dimensions for your needs. If you have more specific requirements or further questions, feel free to ask.

Direct Replacements For

| Brand | Series/Models |

|---|---|

| GGB | LD, LDD, MBZ-B09 |

| SKF | PRM |

| PTI | BMZ, BMB |

| ISB | FB090, FB092, FB091, FB09G, FB08G |

| CSB | CSB090, T90, 09G |

| GLT | BRO-MET, BRO-LUB |

| DE | WB702, WB700, WB802, WB800 |

| COB | M09 |

| Sankyo Oiless | BS |

Applications of Wrapped Bronze Bushing

Material of MYWAY Wrapped Bronze Bushing

They are ideal for a variety of heavy-duty applications, ensuring consistent performance even under harsh conditions.

Materials and Structure

Our bushings are made from top-grade bronze alloys that meet international standards, offering excellent corrosion resistance and high load-bearing capacity

- Outer Layer (Bronze Layer):

- The outermost layer is usually made of bronze, a copper-based alloy primarily consisting of copper and tin, with possible additions of other elements like zinc, lead, or phosphorus to enhance specific properties.

- The bronze layer provides mechanical strength and corrosion resistance, allowing the bearing to operate under minimal or no lubrication conditions.

- Middle Layer:

- Some high-performance wrapped bronze bushings incorporate an intermediate layer of special materials such as polytetrafluoroethylene (PTFE) or other plastics between the bronze and the shaft.

- This layer primarily serves to reduce friction and provide additional lubrication.

- Inner Surface:

- The inner layer may include lubrication grooves or oil holes designed to store lubricant, ensuring continuous lubrication.

- Such designs extend the bearing’s lifespan and reduce maintenance needs.

Comparative Table of Bronze Grades for Bushings

| Bronze Grade | Composition | Wear Resistance | Operating Environment | Lifespan | Analysis |

| C93200 | 83% Copper, 7% Tin, 7% Lead, 3% Zinc | High | Moderate loads, occasional dry running | High | Popular for general machinery due to good machinability and durability. |

| C95400 | 85% Copper, 11% Aluminum, 3% Iron, 1% Other | Very High | High loads, high impact, marine environments | Very High | Best for extreme conditions, offers highest wear resistance and longest lifespan. |

| C86300 | 63% Copper, 25% Zinc, 3% Manganese, 9% Aluminum | High | High loads, rough environments | High | Suitable for heavy-duty applications with high strength and toughness. |

| C90500 | Mostly Copper and Tin | Medium | Moderate loads, requires lubrication | Medium | Ideal for applications where some lubrication is provided and moderate wear resistance is needed. |

| C90700 | High Tin content | Medium to High | High loads, requires good lubrication | Medium to High | Provides enhanced wear resistance under lubricated high-load conditions. |

Wrapped Bronze Bushings: Engineering, Advantages, and Applications

What Are Wrapped Bronze Bushings?

Wrapped bronze bushings, also known as rolled bronze bushings or sleeve bearings, are a fundamental component in the world of sliding bearings. Unlike solid bearings that are machined from a single block of metal, these bushings are manufactured by precision-rolling a strip of high-strength bronze alloy into a cylindrical or flanged shape. This cold-forming process creates a seamless, durable bearing structure that is both cost-effective and high-performing. They are designed to provide an interface between two moving parts, typically a shaft and its housing, reducing friction, absorbing shock, and ensuring smooth operation in a vast array of machinery.

The core material used is a phosphor bronze alloy, most commonly CuSn8 (containing about 8% tin) or CuSn6. This material is chosen for its exceptional wear resistance and inherent lubricity. A defining feature of many wrapped bronze bushings is the pattern of lubrication grooves or diamond-shaped indentations rolled into their inner surface. These features act as reservoirs for grease or oil, providing long-term, automatic lubrication during operation, which significantly reduces maintenance needs and extends the service life of both the bushing and the machinery it serves.

Material Composition and Manufacturing Excellence

The superior performance of wrapped bronze bushings begins with their material composition. The most common alloy, CuSn8, consists primarily of copper (Cu) with approximately 8.5% tin (Sn) and a small amount of phosphorus (P). This specific formulation delivers a unique combination of properties crucial for bearing applications:

Copper (Cu): Serves as the base material, providing excellent thermal conductivity which helps dissipate heat generated by friction, and forms a robust structural foundation.

Tin (Sn): Significantly increases the alloy’s hardness and resistance to wear, making it capable of withstanding heavy loads and repetitive motion.

Phosphorus (P): Acts as a deoxidizer, improving the alloy’s strength and fatigue resistance.

The manufacturing process is equally critical. The process of rolling and calibrating the bronze strip creates a hard, fine-grained surface finish that is ideal for sliding applications. This wrapped method allows for the creation of complex features, such as flanges for axial positioning and the critical lubrication pockets, in a single, efficient process. The result is a bearing with consistent material properties and precise geometries that offer exceptional value compared to more expensive machined alternatives.

Key Technical Advantages and Performance Characteristics

Wrapped bronze bushings are engineered to deliver reliability in demanding conditions. Their design offers several distinct technical advantages:

Exceptional Durability and Load Capacity: Thanks to the hardened nature of the rolled bronze alloy, these bushings can handle high static and dynamic loads. They are particularly well-suited for low-speed, high-load applications and are excellent at managing shock loads and vibrations.

Superior Wear and Corrosion Resistance: The phosphor bronze material is naturally resistant to wear, ensuring a long service life. It also exhibits good anti-corrosion properties, performing reliably in challenging environments, including those exposed to moisture, dust, and certain chemicals.

Self-Lubricating & Low-Maintenance Design: The integrated grease pockets or oil holes are a game-changer for maintenance. They act as a built-in lubrication system, distributing grease evenly across the sliding surface and allowing for extended service intervals. This “set-and-forget” feature makes them ideal for applications where regular maintenance is difficult or costly.

Effective Heat Dissipation: The high copper content allows for efficient heat transfer away from the bearing surface, preventing overheating and premature failure.

Cost-Effectiveness: The wrapped manufacturing process is highly efficient, reducing material waste and production time. This makes wrapped bronze bushings a more economical solution than solid bronze bearings without sacrificing performance.

Common Applications Across Industries

The versatility of wrapped bronze bushings makes them suitable for a wide range of sectors. Common applications include:

Construction and Heavy Machinery: Excavators, cranes, and bulldozers rely on these bushings in pivot points, linkage arms, and undercarriages where high loads and contamination are constant challenges.

Agricultural Equipment: From tractors to combines and harvesting machines, agricultural machinery utilizes these bushings for their durability and ability to operate in dirty, abrasive environments like dust and mud.

Automotive and Transportation: They are found in suspension systems, engine components, and gearboxes, contributing to vehicle safety and performance.

Industrial Machinery: Used in various manufacturing equipment, presses, and conveyor systems, providing reliable support and reducing friction in continuous operation.

Why Choose MYWAY Wrapped Bronze Bushings?

At MYWAY, we have refined the art and science of producing high-performance wrapped bronze bushings. We understand that your machinery’s reliability depends on the quality of its smallest components. That’s why our bushings are engineered to exceed industry standards, offering unparalleled value and performance.

Our commitment to excellence includes:

Premium Material Selection: We use high-purity CuSn8 or CuSn6 bronze alloys to ensure outstanding wear resistance and anti-corrosion properties. Our materials are sourced and verified to guarantee consistent performance batch after batch.

Precision Engineering: MYWAY bushings are manufactured to meet stringent international standards like DIN 1494 and ISO 3547. We offer standard tolerances like H7/h8 and specialize in customized dimensions to perfectly fit your unique application requirements.

Optimized Self-Lubricating Features: Our bushings are equipped with strategically designed lubrication grooves and holes that ensure optimal grease distribution, reducing friction and extending the product’s lifespan with minimal maintenance.

Proven Durability in Harsh Environments: Designed to withstand extreme conditions—including high loads, dust, mud, and moisture—MYWAY bushings enhance the service life of your equipment, reduce downtime, and lower your total operating costs.

Ready to Upgrade Your Equipment with MYWAY?

Choosing the right bushing is a critical decision that impacts productivity, maintenance costs, and machine longevity. With MYWAY, you are not just buying a component—you are investing in a reliable, high-performance solution backed by engineering expertise and a commitment to quality.

Contact us today to discuss your requirements, request a quote, or place an order. Let MYWAY be your trusted partner for high-quality wrapped bronze bushings.

MYWAY Wrapped Bronze Bushing FAQs

1. What is the difference between a wrapped bronze bushing and a solid bronze bushing?

Wrapped bronze bushings are formed by rolling a strip of bronze into a cylindrical shape, which is a cost-effective process ideal for high-volume production and creates a hard wearing surface. Solid bronze bushings are machined from a solid bar, which is more material-intensive and expensive but may be necessary for very large sizes or unique geometries not suited to the wrapping process.

2. Are MYWAY wrapped bronze bushings self-lubricating?

Yes, our standard wrapped bronze bushings feature lubrication grooves or diamond-shaped indentations that act as grease reservoirs, providing excellent long-term lubrication. For applications requiring initial lubrication only, these features significantly reduce maintenance frequency.

3. Can you produce bushings with non-standard dimensions or special features?

Absolutely. MYWAY specializes in customized solutions. We can manufacture bushings with special dimensions, unique flange designs, specific lubrication patterns, or other features to meet the exact specifications of your application. Contact us with your drawings or requirements.

4. What are the typical operating temperatures for your bronze bushings?

MYWAY wrapped bronze bushings are capable of operating effectively within a temperature range of -40°C to +150°C, and can withstand peak temperatures up to 200°C for short periods, depending on the lubrication used.

5. How do I ensure a proper press-fit when installing the bushing?

A proper press-fit is crucial for performance. We recommend following standard engineering practices for interference fits based on the housing material and diameter. The outer diameter of our bushings is manufactured to precise tolerances (e.g., r6 or m6) to ensure a secure fit into a housing bore machined to H7 tolerance.