Recent Posts

Thrust Washers: The Ultimate Guide to Axial Load Management

Introduction: The Unsung Heroes of Rotating Machinery

In the complex world of mechanical engineering, thrust washers play a critical yet often overlooked role in ensuring machinery longevity and performance. These flat, disc-shaped components serve as essential elements in managing axial loads and reducing friction across countless industrial applications. From automotive transmissions to aerospace systems, thrust washers provide the crucial interface that prevents catastrophic equipment failure while maintaining precise axial alignment.

Table of Contents

1. What is a Thrust Washer?

A thrust washer, also known as a thrust bearing washer or thrust plate, is specifically engineered to handle axial loads—forces applied parallel to a shaft’s axis. Unlike radial bearings that support rotating shafts, thrust washers prevent components from moving sideways along the shaft, ensuring they maintain proper axial positioning.

2. Key Functions and Operational Principles

Primary Functions:

Manage axial loads in rotating assemblies

Reduce friction between moving components

Maintain axial alignment of mechanical parts

Prevent metal-to-metal contact between surfaces

Absorb shock and vibration in axial direction

How Thrust Washers Work:

Thrust washers operate by creating a low-friction interface between rotating and stationary components. When axial pressure is applied, the washer surface acts as a sacrificial layer, allowing smooth rotation or oscillation while minimizing wear on both the shaft and housing. This fundamental principle makes thrust washers indispensable for rotational system health.

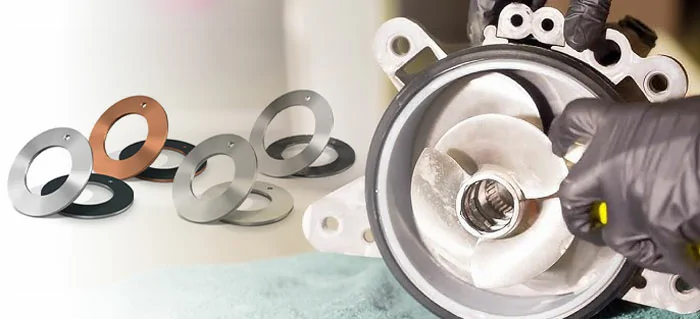

3. Common Materials and Types of Thrust Washers

The performance of a thrust washer is heavily dependent on its material, chosen based on the application’s load, speed, and environmental conditions.

Excellent wear resistance and thermal conductivity

Good compatibility with various lubricants

Ideal for general industrial applications

Available in sintered and cast variations

High-strength steel backing for structural support

Polymer or bronze sinter surface for low friction

Superior durability in heavy-load applications

PTFE/Composite Thrust Washers:

Maintenance-free operation with dry-running capabilities

Excellent chemical resistance

Self-lubricating properties

Ideal for applications where lubrication is challenging

Sintered Bronze Thrust Washers:

Fiber-reinforced composites for specific applications

Custom formulations for extreme conditions

Enhanced wear resistance and load capacity

4. Key Applications of Thrust Washers

The thrust washer application spectrum is vast, covering nearly every sector of industry. You will find a machine thrust washer critical in:

Automotive Sector

Transmission systems managing gear axial pressure

Engine components requiring precise axial positioning

Steering mechanisms ensuring proper alignment

Heavy Equipment and Construction

Gearboxes in mining and construction machinery

Pivot points in heavy-duty equipment

Extreme load applications requiring durability

Aerospace and Defense

Flight control systems demanding precision

Landing gear assemblies requiring reliability

Critical systems where failure is not an option

Industrial Applications

Pumps and compressors ensuring impeller positioning

Marine propulsion systems resisting axial forces

Manufacturing equipment requiring precise alignment

5. Materials and Manufacturing Technologies

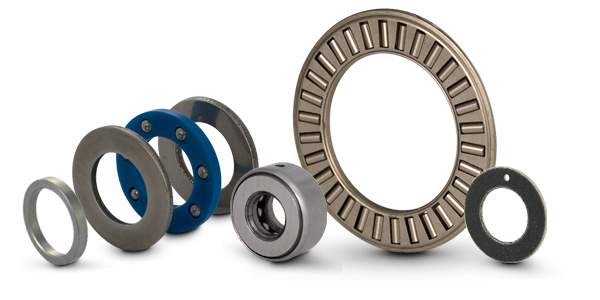

Thrust washers and bearings often work together to support and guide rotating or moving components. Specifically:

- Complementary Functions: Bearings mainly support radial loads (perpendicular to the shaft), such as deep groove ball or roller bearings. Thrust washers, on the other hand, handle axial loads (along the shaft), preventing parts from shifting due to thrust.

- Part of a Thrust Bearing Assembly: In some designs, thrust washers are part of the thrust bearing structure. For example, in thrust ball or roller bearings, washers serve as raceways for rolling elements, supporting and guiding axial movement.

- Alternative Use: In low-speed, light-load, or simpler systems, thrust washers can replace thrust bearings to reduce costs and simplify the design.

- Adjacent Installation: In industrial equipment, thrust washers are often placed next to bearings or between the inner and outer bearing rings to provide spacing, support, and axial displacement control.

6. How are thrust washers different from flat washers?

While they may look similar, thrust washers are far more advanced in both function and design:

| Comparison Item | Thrust Washer | Flat Washer |

| Main Function | Absorbs axial loads, reduces friction, limits axial movement | Distributes bolt pressure, protects surfaces, increases fastener contact area |

| Load Direction | Mainly axial (along the shaft) | Typically doesn’t bear load, static use only |

| Application Scenarios | Rotating shafts, gearboxes, transmissions, pumps with axial movement or thrust | Bolt-fastened structures like flanges or bracket mounts |

| Subject to Friction | Yes, used between moving parts; must resist friction | No, generally placed between stationary parts |

| Material Requirements | Wear-resistant, low-friction, high-strength materials like bronze alloys, steel, PTFE composites | Common materials like carbon steel, stainless steel, rubber |

7. Thrust Washers vs. Bearings

While both components manage movement and loads, they serve complementary roles:

Bearings primarily handle radial loads (perpendicular to shaft)

Thrust washers specialize in axial load management

In many systems, they work together to provide complete rotational support

8. Installation and Maintenance Best Practices

Proper Installation Procedures

Surface Preparation: Ensure contact surfaces are clean and free of contaminants

Dimensional Verification: Confirm proper tolerances before installation

Orientation Check: Verify correct positioning (especially for grooved designs)

Press-Fit Techniques: Use appropriate tools for installation

Alignment Verification: Confirm proper seating and alignment

Maintenance Considerations

Regular inspection for wear patterns

Lubrication maintenance (for non-self-lubricating types)

Monitoring operating temperatures

Periodic alignment checks

Troubleshooting Common Issues

Removing Stuck Thrust Washers

Use specialized bearing pullers or extraction tools

Apply controlled heat if necessary

Employ hydraulic or mechanical presses

For severely damaged units, careful cutting may be required

Identifying Failure Symptoms

Increased axial play

Unusual noise during operation

Elevated operating temperatures

Visible wear or damage

At MYWAY, we understand that thrust washer performance directly impacts overall system reliability. Our engineering expertise delivers:

Custom Design Capabilities

Application-specific material selection

Custom dimensions and configurations

Specialized surface treatments

Prototype development and testing

Quality Assurance

Rigorous material certification

Precision manufacturing processes

Comprehensive performance testing

Consistent quality control standards

Technical Support

Application engineering consultation

Failure analysis and troubleshooting

Custom solution development

Ongoing technical support

10. Frequently Asked Questions

Q: What is a thrust washer?

A: A thrust washer is a precision bearing component designed specifically to handle axial loads—forces parallel to a shaft’s axis. It prevents mechanical components from moving sideways while reducing friction and wear.

Q: How do I remove a stuck thrust washer?

A: Use specialized bearing pullers, apply controlled heat, or employ hydraulic presses. For severely stuck washers, careful cutting with rotary tools may be necessary while preserving the housing integrity.

Q: What does a thrust washer do in practical terms?

A: It maintains axial positioning of rotating components, manages axial loads, reduces friction between surfaces, and prevents wear on expensive machinery components.

Q: Where are thrust washers commonly used?

A: They’re essential in automotive transmissions, industrial machinery, aerospace systems, marine propulsion, and any application with significant axial loads.

Q: What’s the purpose of a thrust washer in a washing machine?

A: In washing machines, thrust washers manage axial loads from the rotating drum, prevent lateral movement, and reduce wear on the main bearing assembly.

Q: How does a propeller thrust washer function?

A: In marine applications, propeller thrust washers transfer axial thrust from the propeller to the hull structure while allowing smooth rotation and preventing shaft damage.

Industry Insights and Future Trends

The thrust washer industry continues evolving with advancements in:

Material Science: New composites and surface treatments

Manufacturing Technologies: Precision engineering techniques

Design Optimization: Computational modeling for performance prediction

Sustainability: Environmentally friendly materials and processes

11. Conclusion: Partnering for Performance

Thrust washers may be small components, but their impact on mechanical system performance is enormous. At MYWAY, we combine engineering excellence with practical solutions to deliver thrust washers that meet your most demanding requirements.

Whether you need standard bronze thrust washers or custom-engineered solutions, our technical team stands ready to provide the expertise and quality you need for optimal performance and reliability.

Ready to Solve Your Axial Load Challenges?

Contact MYWAY today for expert consultation and custom thrust washer solutions tailored to your specific application requirements.

10000+ Types of Thrust Washers – Contact Us for Details