Recent Posts

The Essential Guide to Bronze Alloy Composition for High-Performance Bearings

What Exactly is Bronze? Beyond the Basics

When we talk about bronze, we’re not referring to a single, simple metal. Bronze represents a family of copper-based alloys that has been fundamental to human engineering for millennia. While historically associated with copper and tin, modern industrial bronze encompasses a wider range of formulations. Unlike pure copper (often called red copper) or brass (a copper-zinc alloy), bronze maintains distinct advantages that make it indispensable for demanding mechanical applications, particularly in bearings and bushings.

The magic of bronze lies in its adaptable nature. By varying the type and proportion of alloying elements, metallurgists can engineer materials with targeted properties—enhancing strength, wear resistance, corrosion protection, or, crucially for bearings, self-lubricating capabilities. This guide will explore how the precise composition of bronze alloys forms the foundation of reliable, high-performance bearing solutions.

Table of Contents

1. The Bronze Alloy Family: Types and Characteristics

Modern engineering classifies bronze into several key categories, each with a unique composition profile suited for specific challenges. Understanding these differences is the first step in selecting the right material.

Tin Bronzes (Phosphor Bronzes): The classic bearing bronze. Copper is alloyed primarily with tin (typically 5-12%) and often a small amount of phosphorus. This family, including alloys like C90700 and C93200 (SAE 660), is renowned for its excellent anti-friction properties, good fatigue resistance, and corrosion resistance. They are a go-to choice for general-purpose and heavy-duty sleeve bearings.

Aluminum Bronzes: These alloys replace tin with aluminum (up to 14%) as the primary alloying element, often combined with iron and nickel. Alloys like C95400 offer exceptional strength, high corrosion resistance (especially to seawater), and good wear properties. They are ideal for extreme environments found in marine, mining, and aerospace applications.

Lead Bronzes (Leaded Tin Bronzes): These are tin bronzes with an added percentage of lead (e.g., C93800, C94300). The lead forms soft, dispersed phases within the harder bronze matrix. This structure provides superior embeddability (tolerance to dirt particles), excellent conformability, and improved machinability, making them perfect for applications where alignment is challenging or lubrication is marginal.

Silicon and Manganese Bronzes: These arehttps://mybushing.com/bronze-bushing-2/ high-strength alloys where silicon or manganese is a major component. They offer an outstanding combination of high tensile strength and good corrosion resistance, often used in high-load, low-speed bearing applications and gears.

2. The Revolution of Self-Lubrication: How It Works

The quest for maintenance-free and reliable operation has driven the innovation of self-lubricating bronze bearings. This technology moves beyond traditional oil grooves and periodic greasing, integrating the lubrication directly into the material’s structure. Research in metal-based solid self-lubricating composites has been pivotal in this advancement.

There are two primary methods to achieve self-lubrication in bronze bearings:

Powder Metallurgy (Sintered) Bearings: These are created by pressing and sintering copper and tin powder mixtures. The final product has a controlled, interconnected porous structure, typically comprising 20-30% void space. This porosity is then impregnated with lubricating oil. During operation, heat generated by friction causes the oil to expand and migrate to the bearing surface. As the bearing cools, it re-absorbs the oil. This cycle provides continuous lubrication for thousands of hours.

Solid Composite Bearings: This advanced approach involves uniformly dispersing solid lubricants throughout a solid bronze matrix. Common solid lubricants include:

Graphite: A classic solid lubricant, graphite plugs or flakes are embedded in the bronze. Under pressure, they shear onto the contact surface, creating a low-friction film.

PTFE (Teflon): Offers an extremely low coefficient of friction and is chemically inert.

Other Additives: Materials like molybdenum disulfide (MoS₂) or even ceramic particles such as alumina (Al₂O₃) are added to enhance wear resistance, seizure resistance, and load capacity.

Studies show that well-designed self-lubricating bronze composites can operate reliably with a low and stable coefficient of friction (0.01–0.04) and without external lubrication for 3,000 to 5,000 hours under appropriate conditions.

3. Decoding the Numbers: Key Bronze Alloys for Bearing Applications

| Alloy Common Name | UNS Number | Typical Composition (Key Elements) | Key Properties | Ideal Application Environment |

|---|---|---|---|---|

| High-Leaded Tin Bronze | C93200 / SAE 660 | Cu (81-85%), Sn (6.3-7.5%), Pb (6-8%), Zn (2-4%) | Excellent machinability, good conformability & embeddability, anti-friction. | General-purpose bearings, moderate loads and speeds. |

| Aluminum Bronze | C95400 | Cu (85% min), Al (10-11.5%), Fe (3-5%) | Very high strength, excellent corrosion/erosion resistance, good wear. | Heavy loads, low speeds, seawater/marine, corrosive environments. |

| Manganese Bronze | C86300 | Cu (60-66%), Zn (22-28%), Al (5-7.5%), Mn (2.5-5%), Fe (2-4%) | Highest strength of common bronzes, excellent wear resistance. | Very high-load, low-speed applications, bushings in heavy machinery. |

| Sintered Bronze (for Oil-Impregnated) | — | Cu (89-91%), Sn (9-11%) | Self-lubricating, good wear life, cost-effective for high volumes. | Applications where re-lubrication is difficult; electric motors, appliances, automotive. |

At MYWAY, we don’t just supply bushings; we engineer reliability. Our expertise lies in harnessing the science of bronze composition to solve real-world friction and wear problems. We specialize in advanced solid bronze and powder metallurgy self-lubricating bearings tailored for applications where maintenance is costly, access is limited, or environmental conditions rule out traditional lubricants.

Our Technical Edge:

Material Science Expertise: We go beyond standard alloys. Our engineers can tailor compositions, adjusting tin, lead, graphite, or PTFE content to optimize for your specific PV (Pressure-Velocity) value, temperature range, and environmental exposure.

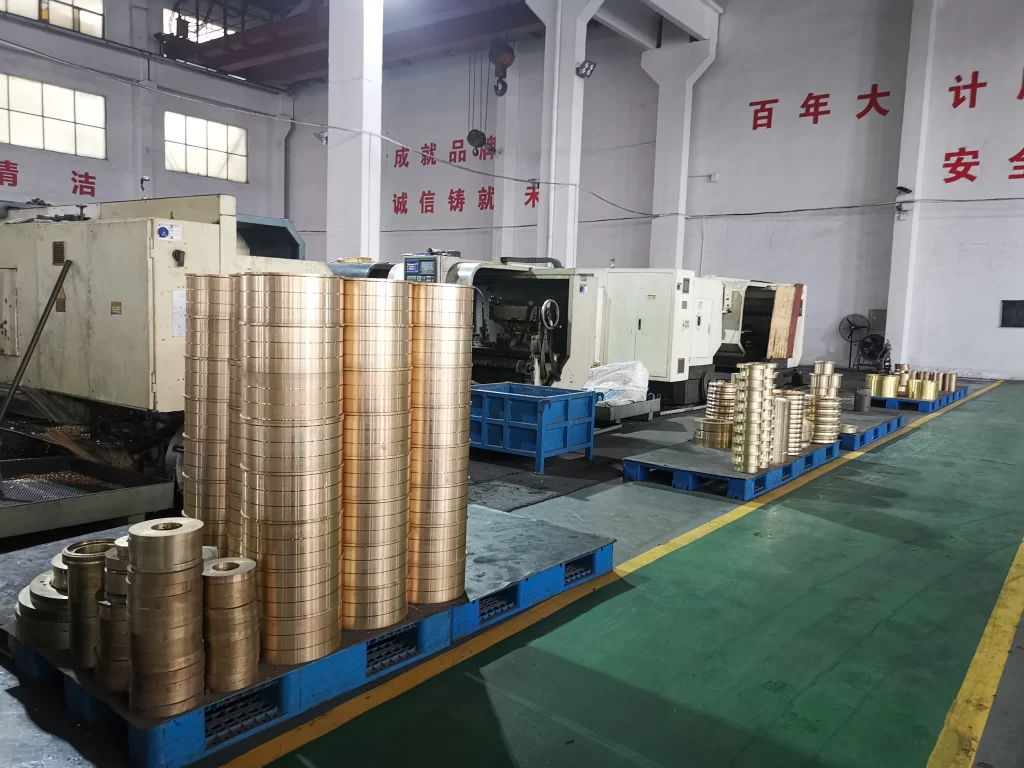

Advanced Manufacturing: Whether it’s precision continuous casting for solid bronze alloys or controlled sintering for oil-impregnated bearings, our processes ensure consistent density, porosity, and mechanical properties in every batch.

Proven Performance: Like the bronze sleeve bearings trusted by NASA in their massive crawler-transporters to move space shuttles, our products are built for mission-critical reliability. We focus on extending service life, reducing downtime, and eliminating lubrication-related contamination.

5. From Concept to Component: Our Process with You

- Application Analysis: We start by understanding your operating conditions—load, speed, temperature, exposure, and desired lifespan.

- Alloy Selection: We recommend the optimal bronze matrix and self-lubrication method (solid lubricant composite or oil-impregnated sintered metal).

- Prototyping & Testing: We can produce sample batches for real-world validation before full-scale production.

- Precision Production & Delivery: We manufacture to precise tolerances, ensuring a perfect fit and function in your assembly.

Ready to eliminate lubrication headaches and boost operational reliability? Contact our engineering team today for a consultation. Let us analyze your needs and provide a quote for MYWAY self-lubricating bronze bushings designed for your success.

Frequently Asked Questions

Q: What’s the main difference between bronze and brass for bearings?

A: While both are copper alloys, brass primarily uses zinc as the main alloying element, making it easier to machine and often more ductile. Bronze, typically alloyed with tin, aluminum, or silicon, generally offers superior strength, wear resistance, and corrosion resistance, making it the more common and reliable choice for high-load, high-wear bearing surfaces.

Q: Can self-lubricating bronze bearings handle high temperatures?

A: It depends on the specific lubricant used. Oil-impregnated sintered bronze is generally suitable for temperatures up to 150-200°F (70-90°C) before the oil degrades or evaporates excessively. Solid lubricant composites (with graphite or PTFE) can often withstand higher temperatures—PTFE-based bearings can operate continuously up to 500°F (260°C). Always consult the manufacturer’s specifications for your operating temperature.

Q: How long do self-lubricating bronze bearings last?

A: Service life is a function of the operating conditions (load, speed, temperature, alignment) and the specific bearing material. Under favorable conditions, well-designed self-lubricating bearings can operate maintenance-free for several thousand hours. For a precise life estimate, a PV calculation and application review with our engineers is recommended.

Q: Are these bearings suitable for food and beverage or pharmaceutical machinery?

A: Absolutely. Self-lubricating bearings with approved solid lubricants like certain PTFE or graphite compounds are ideal for these industries. They eliminate the risk of lubricant contamination of products, meeting stringent FDA and USDA requirements for incidental contact. We can specify materials compliant with relevant hygiene standards.

Q: My application is in a corrosive environment (e.g., seawater, chemicals). What alloy should I use?

A: For highly corrosive environments, aluminum bronze (like C95400) is often the best choice due to its excellent corrosion and erosion resistance. For less severe conditions, high-tin bronzes also offer good corrosion resistance. We can help select the most cost-effective and durable alloy for your specific chemical exposure.

100000+ Types of Bushings – Contact Us for Details