Recent Posts

The Silent Saboteur: What Really Causes Control Arm Bushings to Fail (And How to Stop It For Good)

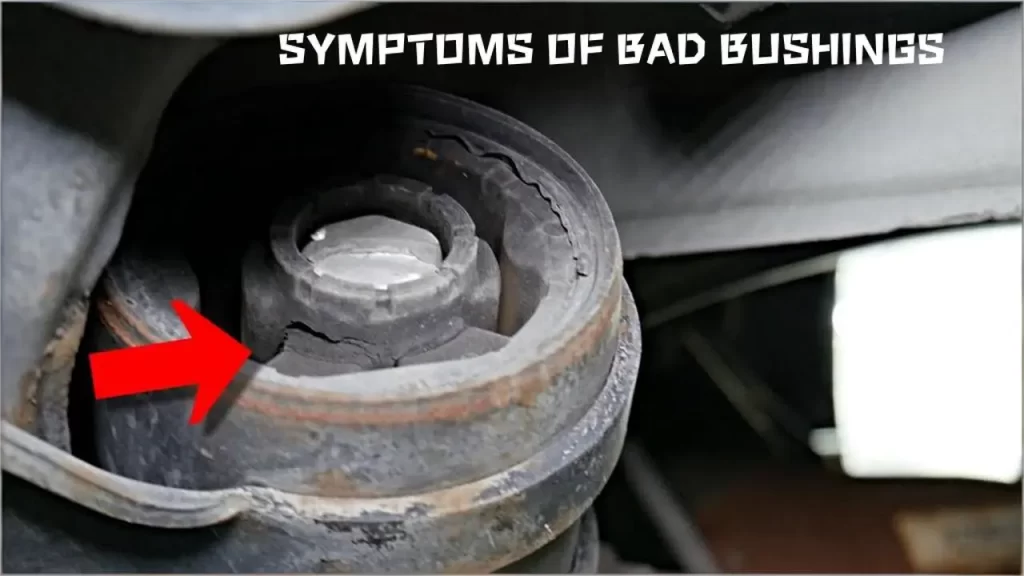

That unsettling clunk when you brake, the steering wheel that shudders over small bumps, or the front end that feels vaguely loose on the highway—chances are, you’ve felt it. Many drivers dismiss these as minor quirks of an aging car. But more often than not, these symptoms point to a critical, yet overlooked, component failing in plain sight: your control arm bushings.

These unsung heroes of your suspension system are the primary reason your car handles smoothly instead of feeling like a shopping cart with a wobbly wheel. When they go bad, it starts a chain reaction of wear, poor handling, and potential safety risks. Let’s dive into what kills these vital parts and how choosing the right replacement, like MYWAY bushings, can not only fix the problem but upgrade your entire driving experience.

Table of Contents

1. The Warning Signs: Is Your Car Trying to Tell You Something?

Before we get into the “why,” it’s crucial to recognize the “what.” Bushing failure doesn’t happen silently. Your vehicle sends clear signals:

The Tell-Tale Sounds: A distinct clunking or knocking noise when going over bumps, accelerating, or braking is the most classic sign. It’s the sound of metal components moving excessively where rubber should be holding them firm.

The Vague Steering Feel: Does the steering feel imprecise or “floaty,” especially at higher speeds? Do you notice the car pulling to one side during hard braking? This is a direct result of worn bushings allowing the suspension geometry to shift.

The Tire Killer: Take a look at your front tires. Are the inner or outer edges wearing down dramatically faster than the center? This uneven tire wear (camber wear) is a costly symptom of misalignment caused by failed bushings.

The Shakes and Vibrations: Vibrations through the steering wheel or floorboard, particularly from the front end, often stem from bushings that can no longer properly dampen road shocks.

If any of this sounds familiar, your bushings are likely crying for help. Ignoring them doesn’t just hurt your comfort—it accelerates wear on your tires, shocks, ball joints, and ultimately, compromises handling safety.

2. The 5 Major Enemies of Your Control Arm Bushings

So, what turns a robust, rubber bushing into a cracked, squishy failure point? It’s usually a combination of these five factors:

a. The Inevitable: Age and Material Fatigue

Like any rubber component, control arm bushings have a finite lifespan. Simply put, time is their enemy. The rubber compounds, often a mix of natural and synthetic polymers, slowly lose their elasticity and resilience through a process called environmental degradation. Exposure to ozone, oxygen, and temperature cycles causes the molecular chains in the rubber to break down. They harden, become brittle, and eventually crack. No matter how gently you drive, this process is always at work.

b. The Elemental Assault: Water, Salt, and Corrosion

This is where driving environment plays a massive role. Bushings live in one of the dirtiest, most exposed areas of your car.

Road Salt & Chemicals: In winter climates, road salt is a bushing’s worst nightmare. It is highly corrosive and accelerates the breakdown of both the rubber and the metal sleeve inside the bushing. Pitting and rust on the metal sleeve create sharp edges that grind and tear the rubber from the inside out.

Water Intrusion: Frequent driving through puddles or deep snow can force water and grime past the bushing’s seals. This contamination acts as an abrasive, wearing down the rubber and washing away any protective lubricants.

c. The Force Factor: Impact and Overload Stress

Every pothole, speed bump, and curb strike sends a shockwave through your suspension. The bushings are designed to absorb these impacts, but there are limits.

Potholes & Road Imperfections: A severe impact can shear, tear, or permanently deform the bushing rubber in an instant. Once its structural integrity is compromised, it will deteriorate rapidly.

Overloading Your Vehicle: Consistently carrying loads heavier than your vehicle’s rated capacity puts sustained, excessive force on the bushings, flattening and stretching them beyond their design limits.

d. The Motion Sickness: Constant Twist and Movement

A control arm bushing’s job is to allow a very specific, controlled amount of movement. It twists and flexes with every turn, brake application, and acceleration.

Torque Reaction: During hard acceleration or braking, the engine and drivetrain torque tries to twist the suspension. The front control arm bushings (especially the rear bushing on a lower control arm) bear the brunt of this twisting force. Aggressive driving dramatically increases this wear.

Design Compromises: Many OEM bushings have voids or hollow sections to tune for ride comfort. However, these voids can become stress concentrators—weak points where cracks begin under repeated flexing.

e. The Human Error: Improper Installation

Even a perfect new bushing can be doomed from the start. A critical mistake during installation is failing to tighten the bushing bolt at the correct ride height. If the car is hanging in the air (wheels drooping) when the bolt is torqued, the bushing is in a pre-twisted, stressed state. When the car is lowered, the bushing is then forced to twist even further just to sit normally, putting it under permanent, extreme tension that leads to a very early failure.

3. The Domino Effect: Why a Failed Bushing Isn't an Isolated Problem

Think of your suspension as a team. When one player (the bushing) slacks off, everyone else has to work harder and eventually fails.

Tire Wear: Failed bushings allow the control arm to shift, altering the wheel’s camber and toe alignment. This causes rapid, uneven tire wear, costing you hundreds in premature tire replacement.

Component Stress: Excessive movement from a bad bushing transfers shock and load directly into the ball joint, tie rod ends, and even the shock absorber mounts, speeding up their failure.

Handling and Safety: Ultimately, precision and predictability are lost. Steering response dulls, braking stability decreases, and in extreme cases, a completely separated bushing can lead to a sudden loss of control.

4. The MYWAY Solution: Engineered to End the Cycle of Failure

At MYWAY, we don’t just make replacement parts—we make reliability upgrades. We’ve engineered our control arm bushings to directly target and defeat the common causes of failure.

| Feature | Common OEM/Cheap Aftermarket Bushing | MYWAY Performance Bushing |

|---|---|---|

| Material | Standard rubber prone to hardening & cracking | Proprietary, oil-resistant compound with superior memory and resilience across extreme temperatures (-40°C to +120°C). |

| Construction | Often has large voids that become stress points. | Optimized void design or solid construction (application-specific) to eliminate weak points and handle higher loads. |

| Corrosion Protection | Basic metal sleeve, prone to rust. | Precision-machined, zinc-plated or stainless steel sleeves to resist corrosion and ensure a perfect bond with the rubber. |

| Durability Focus | Meets minimum OEM specs for cost and comfort. | Engineered for longevity and performance, reducing the total cost of ownership through extended service life. |

Our philosophy is simple: by using superior materials, intelligent design, and rigorous manufacturing standards, we create bushings that restore—and often enhance—the intended handling of your vehicle while providing peace of mind for years and thousands of miles.

Stop compromising with your suspension. Upgrade to the resilience of MYWAY.

Ready to eliminate the clunks, sharpen your steering, and protect your investment? Contact our technical sales team today for a quote, to discuss your specific vehicle application, or to find a distributor near you. Let MYWAY be the last set of control arm bushings you need to buy.

FAQ: Control Arm Bushings

Q: How long should control arm bushings last?

A: There’s no single mileage. Under ideal conditions with gentle driving, 80,000-100,000 miles is possible. However, harsh climates, rough roads, and aggressive driving can cut that lifespan in half. Listen to your car’s symptoms, not just the odometer.

Q: Can I just replace the bushings, or do I need the whole control arm?

A: It depends. If the control arm itself is bent, cracked, or heavily rusted, replace the entire assembly. If the arm is in good shape, pressing in new high-quality replacement bushings like MYWAY is a cost-effective and excellent solution. Many modern “complete” arms come with bushings pre-installed, making that the easier option.

Q: Is driving with a bad control arm bushing safe?

A: It’s a risk that increases over time. While not an immediate catastrophic failure like a broken ball joint, a failed bushing degrades handling, accelerates wear on expensive parts (like tires), and can lead to a sudden loss of vehicle control if it completely separates. We recommend addressing it promptly.

Q: Why do my new bushings squeak?

A: Squeaking is often due to metal-on-metal contact or dry rubber. Ensure the bushing was installed correctly (torqued at ride height!) and that any required lubricants were used on the correct surfaces. Some performance polyurethane bushings require periodic lubrication.

Q: How can I make my new bushings last longer?

A: Avoid harsh impacts (slow down for puddles/potholes), keep your vehicle within its weight limits, and during installation, always follow the manufacturer’s torque procedure and specifications. For the longest life, choose bushings engineered for durability from the start, like MYWAY’s lineup.

100000+ Types of Bushings – Contact Us for Details