Recent Posts

The Quiet Revolution in Plain Bearings: How Modern Materials Are Redefining Reliability

For centuries, the plain bearing—a simple sleeve supporting a rotating shaft—has been a cornerstone of machinery. While rolling-element bearings often steal the spotlight, a significant and quiet evolution is happening within plain bearing technology. Driven by demands for maintenance-free operation, harsh environment durability, and total cost reduction, advanced materials are transforming this fundamental component from a wear item into a high-performance, strategic asset. This article explores the cutting-edge materials defining the future of plain bearings and how making the right choice impacts your machinery’s reliability and bottom line.

Table of Contents

1. Beyond Metal: The Rise of Engineered Polymer and Composite Bearings

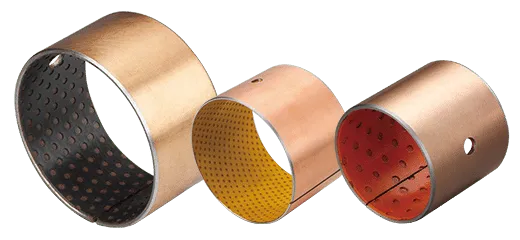

The traditional image of a plain bearing as a bronze or brass sleeve is rapidly expanding. Today’s landscape includes a sophisticated array of metal-polymer composites, filament-wound structures, and specialized impregnated materials, each designed to solve specific engineering challenges.

A primary driver of innovation is the pursuit of true maintenance-free operation. For applications where lubrication is impossible, undesirable, or simply too costly to maintain, self-lubricating bearings are the solution. These bearings integrate solid lubricants like PTFE (Polytetrafluoroethylene), graphite, or other polymers directly into their structure. As the bearing operates, a thin, protective transfer film forms on the mating shaft, providing continuous lubrication without external grease or oil.

Recent regulatory trends are further shaping material development. With increasing scrutiny and potential restrictions on PFAS chemicals (which include PTFE), leading manufacturers are at the forefront of developing high-performance, PTFE-free alternatives that maintain low friction and long service life without regulated substances.

The following table compares the core characteristics of modern plain bearing material families:

| Material Family | Typical Composition | Key Advantages | Ideal Application Examples |

|---|---|---|---|

| Metal-Polymer Composites | Steel/bronze backing + sintered bronze layer + PTFE-based lining. | Excellent wear resistance, low friction, maintenance-free, good load capacity. | Automotive components, general industrial machinery, rotary joints. |

| Engineered Thermoplastics(e.g., iglidur materials) | High-performance polymers with solid lubricant inclusions. | Corrosion-proof, chemically resistant, lightweight, low moisture absorption, cost-effective. | Food & beverage machinery, chemical processing, packaging equipment, agricultural machinery. |

| Filament-Wound Composites | Wound fibers (e.g., glass) in a resin matrix, often with PTFE layers. | Extremely high static and dynamic load capacity, excellent dampening of vibration and shock. | Heavy-duty pivot points in construction equipment (excavators, cranes), marine applications. |

| Impregnated Porous Metals | Sintered bronze or iron powder impregnated with lubricant (oil, PTFE, or blends). | Self-lubricating, good thermal conductivity, relatively low cost. | Small electric motors, household appliances, automotive accessories. |

| Advanced Non-Steel Metallic | Titanium alloys or aluminum with specialized self-lubricating coatings or liners. | High strength-to-weight ratio, excellent corrosion resistance, suitable for extreme environments. | Aerospace, marine, and high-performance automotive systems. |

2. Case in Point: The Tangible Benefits of Material Upgrades

The shift to advanced plain bearings is not theoretical. Real-world case studies demonstrate profound impacts on operational efficiency and cost. A prominent example comes from machine tool manufacturer DMG. They faced challenges with the traditional PTFE-coated metal bearings in their tool changer chains, which experienced wear and required maintenance. After extensive testing, they switched to engineered polymer plain bearings (specifically iglidur D material).

The results were significant: the new bearings provided a consistent coefficient of friction over their entire service life, operated completely maintenance-free, and led to a cost reduction of at least 50%, primarily through the elimination of lubrication and associated downtime. This case underscores a critical insight: the true cost of a bearing encompasses not just its purchase price, but also installation, lubrication, maintenance, and the cost of unplanned downtime.

3. Navigating the Selection Crossroads: Key Questions to Ask

Choosing the optimal plain bearing material is a critical design decision. Moving beyond basic dimensions, engineers must evaluate the application against several key criteria:

Load & Motion Profile: Is the load static, dynamic, or involving shock? Is the motion continuous rotation, slow oscillation, or linear? Heavy shock loads favor toughened composites or metals, while continuous rotation may suit standard metal-polymer types.

Environmental Factors: Exposure to water, chemicals, dust, or extreme temperatures dictates material choice. Polymers excel in corrosive and wet environments, while specialized composites handle high temperatures.

Lubrication Reality: Can the bearing be reliably lubricated? If the answer is “no,” a maintenance-free self-lubricating design is mandatory.

Total Cost of Ownership (TCO): Calculate beyond the unit price. Consider the costs of lubrication systems, maintenance labor, production downtime for greasing, and premature failure. Often, a higher initial investment in an advanced bearing yields the lowest TCO.

At MYWAY, we understand that a bearing is more than a component—it’s a vital element of your system’s reliability. We specialize in providing robust bearing solutions that bridge traditional durability and modern performance needs.

While the industry innovates with polymers and composites, there remains a vast and critical domain where high-strength, wear-resistant metallic bearings are irreplaceable. This is where MYWAY excels. Our expertise lies in engineering and manufacturing:

High-Load Metallic Bushings: For applications demanding ultimate strength and where traditional materials are specified.

Specialized Alloy Solutions: Tailored materials for unique temperature, corrosion, or wear challenges.

Precision and Reliability: Manufactured to exacting standards to ensure performance in demanding industrial, automotive, and heavy machinery applications.

We complement the evolving material landscape by ensuring that when your design calls for metallic bearing performance, you have a source dedicated to quality, consistency, and engineering support.

5. Conclusion: Making the Strategic Choice

The world of plain bearings is no longer simple. It presents a strategic choice that directly affects machine uptime, maintenance costs, and operational efficiency. From maintenance-free polymers revolutionizing light-to-medium-duty applications to advanced composites pushing the boundaries of load and environment, the right material is key.

Are you ready to specify the optimal bearing solution for your next project? Whether you are evaluating a switch to advanced composites for a maintenance-free goal or require a high-performance metallic bushing, informed decisions start with the right partnership.

Contact MYWAY today. Let our engineering team help you analyze your application needs. Request a consultation or a competitive quote for your specific requirements, and leverage our expertise to build greater reliability and efficiency into your equipment.

FAQ: Modern Plain Bearings

Q1: What exactly is a “maintenance-free” plain bearing?

A maintenance-free bearing is designed to operate for its entire service life without the need for external lubrication (grease or oil). This is typically achieved through self-lubricating materials, such as PTFE composites, graphite plugs, or oil-impregnated sintered metals, which create a permanent lubricating film.

Q2: Are polymer/plastic bearings strong enough for heavy machinery?

Yes, modern engineered polymer bearings and fiber-reinforced composites have dramatically increased strength. Materials like filament-wound composites are specifically designed for extremely high static and dynamic loads, successfully used in heavy-duty pivot points for excavators, cranes, and agricultural equipment.

Q3: What’s the biggest advantage of switching from traditional bronze to an advanced polymer bearing?

The most significant advantages are often corrosion resistance and the elimination of maintenance. Polymer bearings will not rust, are immune to many chemicals, and require no lubrication, reducing total lifecycle costs and preventing contamination in sensitive environments like food processing.

Q4: My application involves a lot of vibration and shock loads. What bearing type is best?

For high vibration and shock, filament-wound composite bearings or toughened polymer composites are excellent choices. Their composite structure and inherent material properties allow them to dampen vibrations and absorb impact energy better than brittle materials, preventing cracking and premature failure.

Q5: With potential PFAS/PTFE regulations, are self-lubricating bearings still a future-proof option?

Absolutely. Leading manufacturers are proactively developing and deploying high-performance PTFE-free self-lubricating materials in response to regulatory trends. These new materials aim to deliver the same low friction and long life without relying on substances under scrutiny, ensuring a sustainable path forward.

Q6: When should I still consider a traditional metallic bushing from a supplier like MYWAY?

Stick with high-performance metallic bushings when your application involves: extremely high unit loads that exceed polymer capabilities, very high continuous operating temperatures, existing designs where a direct metal-to-metal replacement is required, or when superior thermal conductivity is critical for heat dissipation.

100000+ Types of Bushings – Contact Us for Details