Recent Posts

Slide Bearings: Selection and Applications

Introduction: Why Slide Bearings Are the Unsung Heroes of Modern Machinery

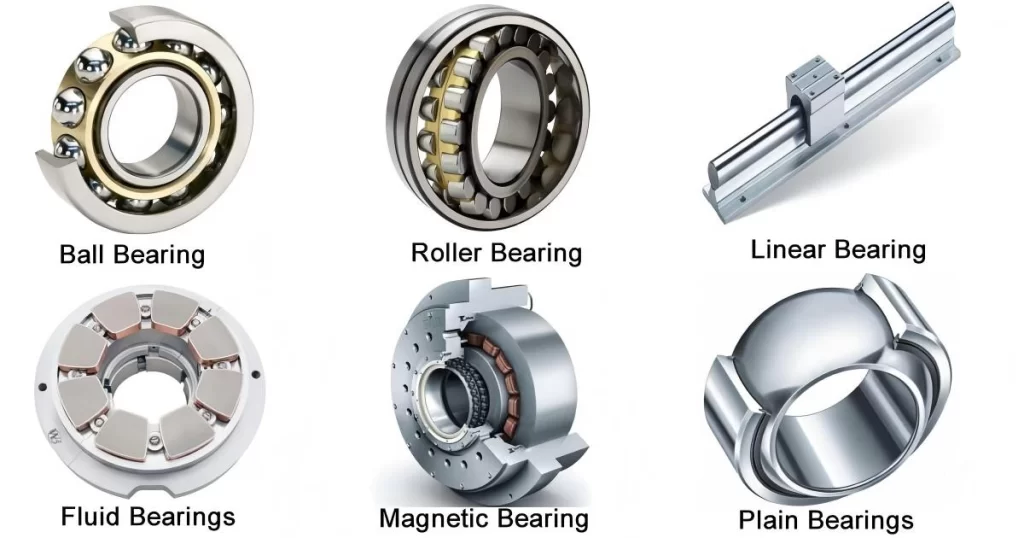

In the heart of countless machines—from the massive hydraulic arm of an excavator to the precise movements of a food processing conveyor—lies a component often overlooked yet vital for smooth operation: the slide bearing, also known as a plain bearing or bushing.

Unlike their more famous cousins, rolling-element bearings, slide bearings operate on a principle of sliding friction. They are prized for their simplicity, exceptional load-carrying capacity, and ability to operate reliably and quietly in challenging conditions where maintenance is difficult or impossible. Whether you’re dealing with low-speed, high-load scenarios, corrosive environments, or applications demanding minimal noise, understanding slide bearings is key to optimal design and cost-effective operation.

This guide will walk you through everything you need to know about slide bearings and introduce you to how MYWAY’s specialized solutions can solve your most demanding application challenges.

Table of Contents

1. Understanding Slide Bearings: Core Concepts and Advantages

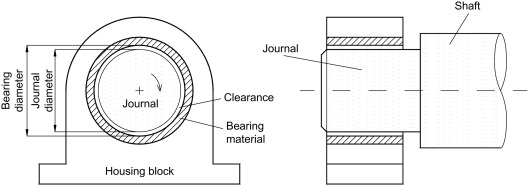

A slide bearing’s primary function is to guide and support a shaft, allowing for rotational or linear movement with minimal friction. Its fundamental advantage stems from its large contact area, which distributes force evenly and makes it exceptionally good at handling heavy radial and axial loads.

Key Advantages:

High Load Capacity & Shock Resistance: Their full-surface contact design makes them ideal for applications with heavy, uneven, or impact loads, such as in construction or mining equipment.

Compact & Simple Design: With fewer parts and a compact radial size, they are often easier to integrate into designs and more economical to manufacture.

Quiet and Vibration-Dampening Operation: The sliding motion is inherently quieter than rolling, and lubricating films can help absorb vibrations.

Suited for Harsh Environments: When designed with the right materials, they can perform reliably under extreme temperatures, in the presence of contaminants, or in submerged conditions.

2. A Detailed Look at Types and Materials

Slide bearings are not one-size-fits-all. They are categorized in several ways to match specific needs.

1. Classification by Lubrication Method

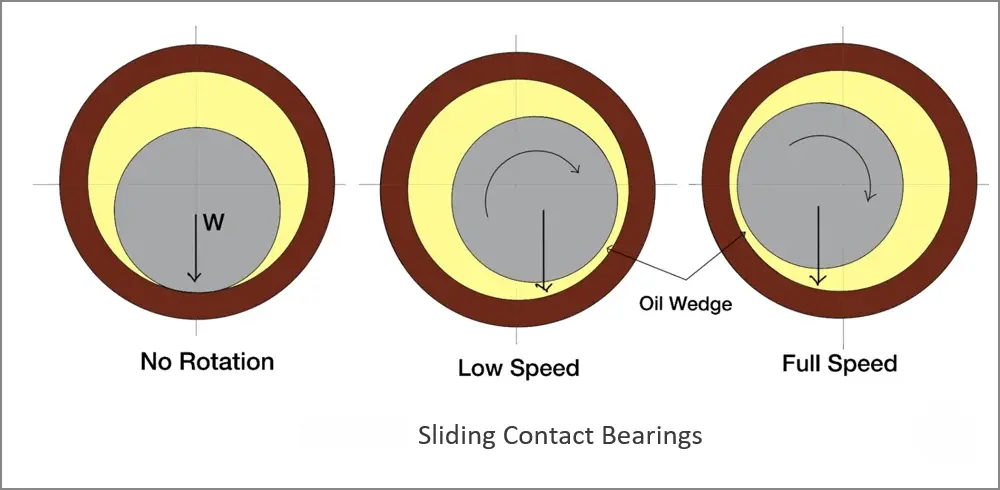

This is a critical differentiator, directly impacting maintenance needs and application suitability.

| Lubrication Type | How It Works | Best For | Considerations |

|---|---|---|---|

| Oil/Grease Lubricated | A continuous film of fluid lubricant separates surfaces. | High-speed, precision applications where maintenance is possible. | Requires maintenance; risk of contamination in clean environments. |

| Solid Lubricated (Self-lubricating) | Lubricants like PTFE, graphite, or lead are embedded in the bearing material, creating a transfer film. | Maintenance-free operation, harsh environments (dust, extreme temps), or clean applications (food, pharma). | May have higher startup friction. |

| Water Lubricated | Uses water as the lubricating medium. | Marine applications, pumps, or where oil pollution is a concern. | Requires compatible, corrosion-resistant materials like polymers or ceramics. |

| Gas Lubricated | Uses a thin film of air or other gas. | Ultra-high-speed, high-precision spindles, or vacuum environments. | Very low load capacity; requires clean, dry air supply. |

Self-lubricating bearings, a specialty of MYWAY, have revolutionized industries by eliminating lubrication schedules and reducing downtime.

2. Classification by Structure and Load Direction

Radial/Journal Bearings: Support loads perpendicular to the shaft axis. The most common type, often simply called a bushing or sleeve bearing.

Thrust Bearings: Support loads parallel to the shaft axis (axial loads).

Flanged Bushings: Combine radial support with a flange for easy axial location and light thrust load capacity.

Spherical Plain Bearings: Accommodate shaft misalignment while supporting combined radial and axial loads.

Split Bearings: Made of two halves, allowing for easier installation and replacement without dismantling surrounding equipment.

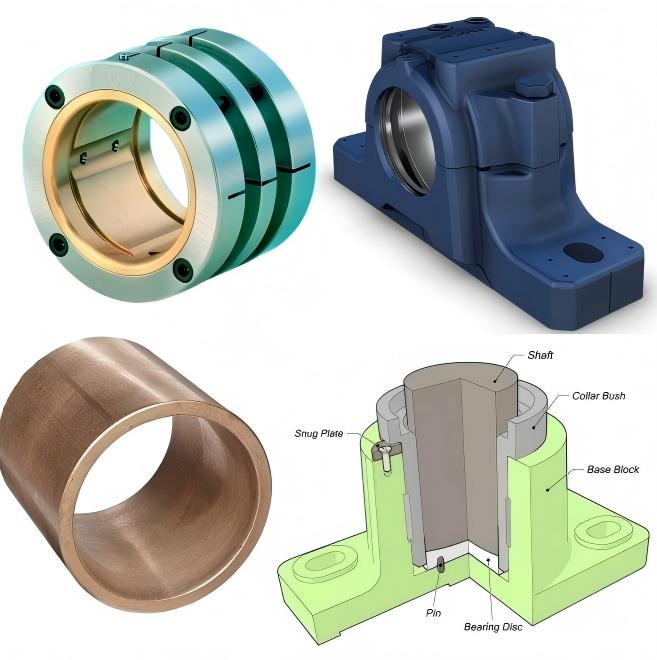

3. Bearing Materials: The Foundation of Performance

The choice of material directly affects wear, friction, corrosion resistance, and load capacity.

Bronze & Brass: Traditional, durable materials with good wear resistance and thermal conductivity. Common in general industrial applications.

Bimetal & Polymer Composites (The MYWAY Specialty): These advanced materials combine the strength of a metal backing (like steel or copper) with a surface layer of low-friction polymer (like PTFE or POM). They offer an excellent balance of high load capacity, embedded lubrication, and corrosion resistance.

Engineering Plastics: Materials like nylon, POM, or UHMWPE are lightweight, corrosion-proof, and work well in wet or chemically aggressive environments.

3. How to Select the Right Slide Bearing: A Practical Guide

Selecting the optimal slide bearing involves answering a series of key questions about your application. Use this checklist to gather the information needed for a precise selection or to provide to a supplier like MYWAY for a expert recommendation.

1. Load Conditions:

What is the magnitude and direction of the load (radial, axial, or combined)?

Is the load constant, variable, or shock/impact in nature?

2. Motion & Operating Conditions:

What is the rotational or linear speed?

What is the operating temperature range?

What is the environment? (e.g., exposed to dust, moisture, chemicals, or requiring cleanliness)

3. Shaft & Installation Details:

What is the shaft material, hardness, and surface finish?

What are the precise housing dimensions and tolerances (ID, OD, length)?

Is there potential for shaft misalignment?

4. Performance & Maintenance Expectations:

What is the required service life?

What are the lubrication and maintenance possibilities? Is “maintenance-free” a goal?

Are there noise or vibration restrictions?

4. Where Slide Bearings Shine: Industry Applications

The versatility of slide bearings makes them indispensable across a wide spectrum of industries:

Automotive: In shock absorber bushings, steering linkages, and pivot points for their durability and noise reduction.

Construction & Agriculture: In excavator arms, loader linkages, and tiller bearings where they withstand heavy loads, shock, and contaminated environments.

Industrial Machinery: As guide bushings in hydraulic cylinders, pivot points in packaging equipment, and supports in conveyor systems.

Marine & Hydraulics: In rudder systems, pump components, and valve controls, especially where water lubrication or extreme corrosion resistance is needed.

Real-World Insight: A manufacturer of high-end jogging strollers replaced a complex metal gear assembly with simple spherical sliding bearings. This switch simplified assembly, reduced weight and cost, and provided the multiple degrees of freedom needed for a natural arm motion—all without requiring lubrication.

5. Introducing MYWAY: Your Partner for Advanced Bushing Solutions

At Zhejiang MYWAY Co., Ltd., we don’t just manufacture bushings; we engineer reliable, high-performance solutions for the world’s most demanding applications. With years of expertise as an industry manufacturer specializing in self-lubricating technology, we understand the critical role a well-designed bushing plays in your product’s performance and longevity.

Our Core Expertise: Self-Lubricating Composite Bushings

Our flagship products are metal-polymer composite bushings, a sophisticated material technology we have mastered.

The MYWAY DU/SF-1 Bushing: A Study in Advanced Design

A prime example of our engineering capability is our DX/SF-2 series boundary lubrication bearing. Its layered structure is designed for optimal performance:

Steel Backing Layer: Provides high structural strength and excellent load-bearing capacity.

Porous Bronze Sinter Layer: This intermediate layer is sintered onto the steel. It ensures a permanent bond with the top layer and enhances heat dissipation away from the friction surface.

PTFE/Lead Mixture Top Layer (0.01-0.03mm): This is the working surface. During operation, it forms a thin, protective transfer film on the mating shaft, providing superior dry-running, low-friction performance and protecting both components from wear.

Why Choose MYWAY?

Focused Quality Control: We employ tungsten steel precision molds and laser optical measurement to ensure high dimensional accuracy and superb surface finish for every bushing.

Proven Global Reach: Our products are trusted by partners worldwide, evidenced by our active export history to diverse markets.

Customization & Support: We offer custom solutions and work closely with you to select or design the bushing that perfectly fits your unique application, load, and environmental conditions.

6. Ready to Find Your Perfect Bushing Solution?

Navigating the world of slide bearings can be complex, but you don’t have to do it alone. Whether you need a standard self-lubricating bushing, a fully custom-designed component, or expert advice on selecting the right material for a challenging new application, MYWAY is here to help.

Contact us today to discuss your project requirements, request a quote, or learn more about how our DU/SF-1 and other advanced bushing solutions can enhance the reliability and performance of your machinery. Let’s turn your bearing challenges into your competitive advantage.

7. Frequently Asked Questions (FAQ)

Q1: What’s the main difference between a rolling bearing and a slide bearing?

The core difference is the type of friction. Rolling bearings use rolling elements (balls, rollers) to reduce friction, offering very low startup friction and efficiency at high speeds. Slide bearings use sliding contact, offering higher load capacity in a more compact size, better shock absorption, and are often more suitable for low speeds, harsh environments, or where maintenance is undesired.

Q2: When should I choose a self-lubricating bushing?

Choose self-lubricating bushings when maintenance is impractical, expensive, or undesirable; when the operating environment is dirty, wet, or extreme; or when lubrication could contaminate a process (e.g., in food, textile, or pharmaceutical equipment).

Q3: How do I know if my application needs a custom bushing size?

If your shaft size, housing bore, or length is non-standard, or if you have specific performance requirements under unique load or temperature cycles, a custom bushing is the best path. MYWAY specializes in translating these custom requirements into production-ready solutions.

Q4: Can slide bearings handle high speeds?

While traditionally suited for low to moderate speeds, advances in materials (like specialized polymers) and lubrication (like gas bearings) have enabled slide bearings to operate in increasingly high-speed applications. The key is matching the bearing type, material, and lubrication method to the specific speed and load requirement.

Q5: What information do I need to provide to get an accurate quote for bushings?

To help us provide you with the best solution and a precise quote, please have the following ready: a technical drawing (with ID, OD, length, and tolerances), material preference, details on load (type and amount), operating speed, environmental conditions, and your required quantity.

8. Conclusion: Your Trusted 608 Bearing Partner

The 608 bearing’s exceptional versatility and reliability make it a critical component across countless industries. By understanding the detailed specifications, material options, and application requirements outlined in this guide, you can make informed decisions that optimize performance and longevity. Our comprehensive range of 608 bearings, backed by stringent quality control and technical expertise, ensures you receive solutions precisely matched to your operational needs.

Contact our technical team today for personalized recommendations, sample requests, or detailed quotations. Let us help you select the perfect 608 bearing solution for your specific application requirements.

FAQ: Comprehensive 608 Bearing Guide

What do the different suffixes mean in 608 bearing codes?

Suffixes indicate sealing type: Z (metal shield), ZZ (double shield), RS (rubber seal), 2RS (double rubber seal)

How do I choose between shielded and sealed bearings?

Metal shields (ZZ) offer better speed capability, while rubber seals (2RS) provide superior contamination protection

What are the temperature limits for different 608 bearing types?

Standard steel: -30°C to +120°C

Stainless steel: -30°C to +150°C

High-temperature variants: up to +250°C

How important is the ABEC rating for my application?

ABEC-1 sufficient for most applications; ABEC-3 or higher recommended for precision equipment

What lubrication options are available?

Standard grease, high-temperature grease, oil, or dry lubrication for specific environments

100000+ Types of Bushings – Contact Us for Details