Recent Posts

A Guide to Sliding Bearings and Why They Outperform

Introduction to Sliding Bearings

In the vast and intricate world of industrial machinery, where components whir, grind, and bear immense forces, there exists a quiet, fundamental workhorse often overlooked: the sliding bearing, also commonly known as a plain bearing or bushing. Unlike their more celebrated cousins, the rolling element bearings, sliding bearings operate on a deceptively simple principle—surface-to-surface contact lubricated by a thin film. This straightforward design belies a remarkable capacity for handling extreme loads, absorbing punishing shocks, and operating reliably in some of the most demanding environments imaginable. From the colossal hinges of excavator arms to the precise movements within hydraulic systems, sliding bearings form the crucial, low-friction interface that allows for controlled motion and rotation.

Their role is foundational. By providing a smooth, supportive surface for a shaft (journal) to rotate or slide against, they minimize wear, reduce energy loss, and extend the service life of the entire assembly. While rolling bearings excel in high-speed, precision applications, sliding bearings are the champions of high-load, low-to-moderate speed scenarios where durability under stress is paramount. For engineers and procurement specialists in industries like heavy construction, mining, and energy, understanding the nuances of sliding bearing technology is not just academic—it’s a critical factor in optimizing machine performance, minimizing unplanned downtime, and controlling long-term operational costs. This guide delves deep into the science, advantages, and practical applications of sliding bearings, culminating in how advanced solutions from specialists like MYWAY Bushings are pushing the boundaries of what this essential component can achieve.

Table of Contents

1. How Sliding Bearings Work: The Science of Simple Contact

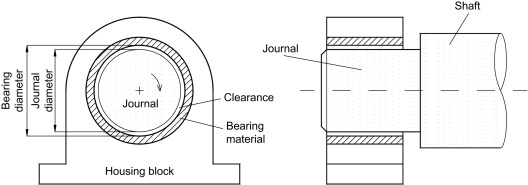

At its core, a sliding bearing is an exercise in elegant simplicity. Its most basic form consists of just two primary parts: the bearing housing or shell and the journal (the part of the shaft that contacts the bearing). The magic—and the engineering challenge—lies in what happens between these two surfaces. The goal is to maintain a continuous film of lubricant that fully separates the metal (or composite) surfaces, thereby replacing solid-on-solid friction with the much lower internal friction of the lubricant itself. This state is known as hydrodynamic lubrication.

Imagine trying to slide two wet pieces of glass apart versus two dry, rough pieces of sandpaper. The principle is similar. During operation, as the shaft rotates, it draws lubricant (oil, grease, or a solid film) into a converging wedge-shaped gap. This action generates enough pressure within the fluid film to lift the shaft slightly, creating that vital separation. This process is why sliding bearings can sometimes exhibit higher starting friction before the film is established, but then run with remarkably smooth and quiet operation.

This fundamental operating principle translates into several inherent design advantages. The surface contact area, as opposed to the point or line contact in rolling bearings, is significantly larger. This large contact area is the key to their exceptional load-bearing capacity and innate ability to dampen vibrations and absorb shock loads. A sudden impact or heavy load is distributed over a broad area, preventing stress concentration and potential catastrophic failure. Furthermore, the simplicity of the design allows for a more compact radial dimension, making sliding bearings ideal for applications where space is at a premium. Their construction is often less complex, which can lead to lower initial manufacturing costs and easier installation in certain configurations.

2. Key Advantages: Why Choose a Sliding Bearing?

The decision to specify a sliding bearing over a rolling bearing hinges on a clear set of performance characteristics where sliding bearings are unmatched. These advantages solve specific, costly problems in industrial applications.

Exceptional Load Capacity and Shock Resistance: This is the foremost advantage. The large surface contact area allows sliding bearings to support radial loads that would overwhelm similarly sized ball or roller bearings. They are indispensable in applications like crankshafts, connecting rods, and the pivot points of earth-moving equipment, where loads are not just heavy but can be suddenly applied. The bearing material itself can deform slightly to accommodate shock, protecting both the shaft and the surrounding machinery.

Superior Vibration Damping and Quiet Operation: The oil film or compliant material in a sliding bearing acts as a natural vibration damper. It absorbs and dissipates energy from vibrations, leading to smoother machine running and significantly reduced noise levels. This makes them the preferred choice for applications where noise pollution is a concern, such as in residential-area machinery or precision instruments, and for enhancing operator comfort in cabins of construction vehicles.

Compact Design and Cost-Effectiveness: With no need for rolling elements, cages, or complex outer rings, sliding bearings often have a simpler and more space-efficient design. This allows engineers to design more compact assemblies. From a cost perspective, the simpler design typically translates to a lower upfront cost for the component itself. For applications requiring very large diameter bearings, the cost savings compared to an equivalent rolling bearing can be substantial.

High Reliability and Contamination Tolerance: In dirty or dusty environments—think mining, agriculture, or forestry—contamination is a constant threat. Rolling bearings can fail quickly if debris becomes embedded in the raceways. Sliding bearings, particularly self-lubricating types with embedded lubricants, are far more forgiving. Particles can often be embedded into the softer bearing material or washed away by the lubricant without causing immediate failure. Certain designs also tolerate misalignment better than rigid rolling bearings.

Long Service Life with Proper Maintenance: Under ideal hydrodynamic lubrication conditions, the shaft and bearing are completely separated by the oil film, resulting in virtually no wear. In theory, their lifespan can be unlimited. While real-world conditions vary, properly maintained sliding bearings in suitable applications often outlast rolling bearings, which have a finite fatigue life determined by their rolling elements and raceways.

3. Sliding Bearings vs. Rolling Bearings: A Clear-Cut Comparison

Choosing the right bearing is not about finding a “better” type, but the optimal tool for the specific job. The following table and analysis clarify the distinct operational niches of sliding (plain) bearings and rolling (ball/roller) bearings.

Table: Performance Comparison: Sliding Bearings vs. Rolling Bearings

| Application Factor | Sliding Bearings (Bushings) | Ball / Roller Bearings |

|---|---|---|

| Load Capacity | Excellent for high, especially shock, loads. Load spread over large area. | Good for moderate loads; excellent for combined loads with specific types. |

| Speed Capability | Best for low to moderate speeds. High-speed requires sophisticated lubrication. | Ideal for high and very-high-speed applications. |

| Friction & Startup | Higher startup friction; lower running friction with full film. | Very low friction from startup. |

| Precision & Rigidity | Good running accuracy; lower rigidity. | Excellent high precision and rigidity. |

| Maintenance Needs | Critical and often higher; relies on consistent lubrication system. | Generally lower; many are sealed and pre-lubricated for life. |

| Contamination Tolerance | Generally higher tolerance to dirt and debris. | Very low tolerance; seals are critical. |

| Noise & Vibration | Very quiet; excellent vibration damping. | Can generate more noise, especially at high speeds. |

| Radial Space | Compact design. | Requires more radial space. |

| Initial Cost | Typically lower cost, especially for large sizes. | Typically higher cost for equivalent size. |

Making the Strategic Choice:

Choose Sliding Bearings when: Your primary challenges are extreme load, impact forces, vibration, or contamination. They are the default for large, heavy-duty rotating equipment like turbines, generators, and the pivotal joints of construction machinery (excavator arms, crane rotations). Their quiet operation and compactness also make them ideal for applications where noise is a factor or space is limited within a housing.

Choose Rolling Bearings when: Your application demands high rotational speed, extreme precision, low starting torque, or minimal maintenance in a clean environment. They dominate in electric motors, machine tool spindles, gearboxes, and precision mechanical assemblies.

The key takeaway is that these bearings are complementary technologies. A modern piece of heavy equipment, like a hydraulic excavator, will strategically use both: rolling bearings in its drive motors and fan assemblies for speed, and robust, custom-engineered sliding bearings throughout its work mechanism to handle brutal digging forces.

4. Types and Materials: The Building Blocks of Performance

The performance of a sliding bearing is intrinsically linked to its construction type and the material from which it is made. Engineers select from these options to match the specific demands of load, speed, environment, and maintenance schedule.

Common Structural Types:

Solid (or Plain) Bushings: The simplest type, a one-piece cylinder. They are pressed or slid into a housing. Ideal for standard applications and replacements.

Split Bushings: Consist of two halves, secured by a cap and bolts. This design allows for easy installation and replacement without needing to disassemble other components, making them perfect for large crankshafts and connecting rods.

Flanged Bushings: Feature a radial flange at one end to provide axial location and thrust load capacity in addition to radial support.

Self-Lubricating / Maintenance-Free Bushings: Incorporate lubricant (like PTFE, graphite, or oil) directly into a composite or sintered metal matrix. They are ideal for hard-to-reach locations or applications where regular lubrication is impossible.

Critical Material Choices:

The bearing material, or lining, is where much of the innovation occurs. It must be soft enough to embed particles and conform slightly, yet strong enough to handle pressure.

Bronze Alloys: The workhorse of the industry. Sintered bronze (powder metal) is porous and can be oil-impregnated for self-lubrication. Cast bronze offers high strength and good thermal conductivity for dissipating heat. Bronze bearings excel in high-load, low-speed applications and are known for their durability.

Babbitt (White Metal): A soft, tin- or lead-based alloy often used as a thin lining over a stronger shell. It has excellent conformability and embeddability, making it a top choice for high-speed, precision applications like turbine bearings where perfect surface conformity is needed.

Polymers and Composites (PTFE, Nylon, Acetal): These materials offer inherent low friction, corrosion resistance, and the ability to run dry or with minimal lubrication. PTFE-based composites are standard in food processing and chemical industries where contamination from lubricants is unacceptable.

Specialized Materials: For the most extreme applications, materials like graphite-impregnated metals (for high temperatures) or thermoset resins with fiber reinforcement are used to tackle unique challenges of heat, corrosion, or extreme wear.

5. Advanced Solutions for Modern Challenges: The MYWAY Bushings Approach

In today’s engineering landscape, standard, off-the-shelf bearings are often insufficient. Demands for higher efficiency, longer service life, and operation in more extreme conditions require a solutions-oriented partner. This is where specialized manufacturers like MYWAY Bushings make a decisive impact.

MYWAY doesn’t just sell bushings; it engineers High-Performance Bearing Solutions. Recognizing that friction, wear, and unplanned downtime are among the biggest costs in industrial operations, MYWAY focuses on advanced technologies that directly address these pain points.

Core Technological Focus:

Self-Lubricating Bronze Bushing Technology: A cornerstone of MYWAY’s offering. By expertly engineering the porosity and oil reservoir system within sintered bronze, they create bushings that provide consistent, long-term lubrication without external grease points. This technology is a game-changer for sealed-for-life assemblies or components in remote, maintenance-hostile environments.

Custom-Engineered Bronze Alloys: Not all bronze is the same. MYWAY utilizes and formulates specific bronze alloys (like high-strength aluminum bronze or lead-free alternatives) to optimize for properties like load capacity, thermal conductivity, corrosion resistance, and compatibility with various shaft materials.

Precision Manufacturing for Optimal Performance: The benefits of advanced materials are only realized with precision manufacturing. MYWAY’s processes ensure tight tolerances, excellent surface finishes, and consistent quality. This precision translates to quicker break-in periods, more stable oil film formation, and ultimately, predictable and extended bearing life.

Solving Real-World Industry Problems:

MYWAY’s expertise is particularly valuable in sectors where failure is not an option. For example, in the engineering machinery sector—serving giants like Sany, XCMG, and LiuGong—MYWAY provides custom bushings for critical applications:

Hydraulic Cylinder Bearings: Where extreme shock loads and continuous oscillation demand a bearing that can dampen vibration and resist deformation.

Undercarriage and Swing Circle Bearings: In excavators and cranes, these components face constant contamination from dirt and moisture. MYWAY’s solutions emphasize superior sealing integration and material choices that tolerate this environment.

High-Load Pivot Points: For articulation joints, MYWAY designs bearings with optimized wall thickness and lubrication grooves to ensure even pressure distribution and prevent the lubricant starvation that leads to premature wear.

By moving beyond a commodity supplier mindset to become a technical partner, MYWAY helps clients minimize total cost of ownership. A slightly higher initial investment in a correctly engineered MYWAY bushing pays dividends through reduced downtime, lower maintenance labor costs, and the avoidance of costly secondary damage to shafts and other components.

Conclusion

From the fundamental principle of hydrodynamic lift to the advanced material science in modern self-lubricating composites, the sliding bearing remains a cornerstone of reliable mechanical design. Its unparalleled ability to manage extreme loads, dampen destructive vibrations, and survive in contaminated environments ensures its irreplaceable role in industries that power our world.

Understanding the detailed comparison with rolling bearings empowers you to make the technically and economically sound choice for every pivot, rotation, and oscillation in your equipment. When that choice points toward a sliding bearing, settling for a generic option can mean leaving performance, durability, and cost savings on the table.

This is where your partnership with MYWAY Bushings begins. Don’t let bearing selection be an afterthought. A poorly chosen bearing is a pivot point for failure; a correctly engineered MYWAY bushing is a foundation for durability.

7. Frequently Asked Questions (FAQ)

Q1: How long does a sliding bearing typically last?

There is no single answer, as lifespan depends entirely on the application (load, speed, temperature), lubrication, and alignment. A properly sized and maintained sliding bearing in a clean, well-lubricated system can last for decades—essentially the life of the machine. In harsh conditions, life is shorter but can be significantly extended by choosing the right material (like a robust MYWAY bronze alloy) and ensuring a proper maintenance schedule. Fatigue life, a key limiter for rolling bearings, is less of a concern for sliding bearings under stable hydrodynamic lubrication.

Q2: When should I choose a self-lubricating bushing over one that requires grease?

Choose self-lubricating bushings when: the bearing location is inaccessible for regular maintenance; your application is in a clean environment where grease leakage is unacceptable (e.g., food packaging); or you want to simplify assembly design by eliminating grease fittings and seals. For extremely high-load or high-speed applications where a continuous, pressurized oil film is required, a traditionally lubricated system may still be necessary.

Q3: Can sliding bearings handle high speeds?

They can, but with important caveats. Standard sliding bearings are best suited for low to moderate speeds. For very high speeds, specialized designs are required, such as hydrodynamic journal bearings with precise oil feed systems or hydrostatic bearings that use externally pressurized oil to create the separating film. These are complex systems used in applications like turbochargers and high-speed spindles. For most industrial applications, rolling bearings are the simpler choice for high-speed needs.

Q4: My application has both heavy loads and some misalignment. What should I look for?

This is a common challenge where sliding bearings often excel. Look for materials with good conformability and embedability, like certain bronze alloys or babbitt-lined bearings. You can also consider spherical plain bearings (a type of sliding bearing) that are specifically designed to accommodate significant misalignment while carrying heavy loads. MYWAY’s engineering team can advise on the optimal geometry and material to handle this combined stress.

Q5: Why should I partner with MYWAY instead of buying standard catalog parts?

Standard parts are designed for average conditions. If your application is critical, operates at the edge of performance envelopes, or exists in a harsh environment, a standard part may lead to premature failure. MYWAY provides application-specific engineering, from material selection and lubrication design to custom dimensions and tolerances. This collaborative approach ensures you get a component that is not just a “bearing,” but a reliability solution designed to maximize uptime and performance in your specific machinery.

100000+ Types of Bushings – Contact Us for Details