Recent Posts

Flanged Sleeve Bearings Explained: Your Guide to Durable, Low-Friction Machine Design

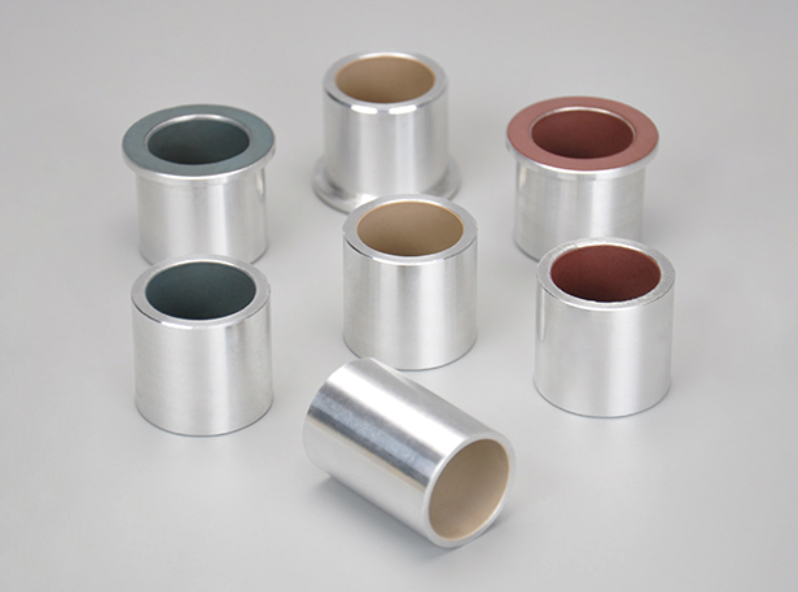

Flanged sleeve bearings are the simple yet vital components that enable smooth machine operation under both radial and thrust loads. As the cornerstone of efficient machinery, they are engineered to minimize friction and wear, translating to less downtime, lower maintenance costs, and extended equipment life. This guide delves into their design, advantages, and key applications, concluding with an introduction to how MYWAY‘s innovative solutions can meet your most demanding engineering challenges.

Table of Contents

1. What Exactly Are Sleeve Bearings?

At their core, sleeve bearings—also known as plain bearings, journal bearings, or bushings—are one of the most fundamental types of bearings. Unlike ball or roller bearings that use rolling elements, sleeve bearings operate on a simple sliding principle. A cylindrical sleeve (the bearing) supports a rotating or sliding shaft, with a thin film of lubricant separating the two surfaces to minimize friction and wear.

The term “sleeve bearing” encompasses various designs. The most basic is the cylindrical sleeve. When this sleeve is extended with a radial collar or flange at one end, it becomes a flanged sleeve bearing. This flange serves a critical function: it allows the bearing to be securely mounted and provides a surface to absorb thrust loads—forces parallel to the shaft’s axis. This combination of radial and axial support in a single, compact unit is what makes flanged designs exceptionally versatile.

2. Inside a High-Performance Bearing: Material Science at Work

The true performance of a modern sleeve bearing is determined by its material composition. Advanced bearings use a multi-layer composite structure, each layer engineered for a specific purpose. A common high-performance configuration includes:

Wear-Resistant Surface Layer (0.01–0.03mm): The top layer is often a mixture of modified PTFE (Teflon) and lead. This material provides an exceptionally low coefficient of friction and forms a protective transfer film on the mating shaft during operation, preventing metal-to-metal contact and protecting the shaft from wear.

Porous Intermediate Layer (0.2–0.3mm): Beneath the surface lies a layer of sintered spherical bronze powder. This porous metal layer acts as a robust substrate, bonding the PTFE to the backing. More importantly, it acts as a reservoir for lubricant (in lubricated designs) and efficiently conducts heat away from the sliding surface.

High-Strength Backing (0.7–2.3mm): The foundation is typically a strip of low-carbon steel. This backing gives the bearing its structural integrity, high load-carrying capacity, and resistance to deformation under pressure. The steel back can also be plated (e.g., copper-tin plating) for enhanced corrosion resistance.

This composite approach is a prime example of powder metallurgy anti-friction technology, which allows for the precise combination of different material properties—like strength, thermal conductivity, and self-lubrication—into one superior product.

3. Material Comparison Table: Choosing the Right Bearing

Different applications demand different material solutions. Here’s a comparison of common sleeve bearing types:

| Material Type | Key Characteristics | Typical Applications | Friction & Lubrication |

|---|---|---|---|

| PTFE Composite | Very low friction, chemical resistant, wide temp. range (-195°C to +280°C), good wear life | Food processing, chemical pumps, clean-room automation, dry applications | Self-lubricating / Dry Running |

| Oil-Impregnated Sintered Bronze | Porosity holds lubricant, good heat dissipation, cost-effective | Small electric motors, household appliances, power tools | Self-lubricating (Oil) |

| Sintered Metal with Graphite | Solid lubricant embedded in metal matrix, stable at higher temperatures | Ovens, conveyors, automotive accessories | Self-lubricating (Solid) |

| Babbitt (White Metal) | Excellent conformability and embeddability, prevents shaft damage | Turbines, large diesel engines, crankshaft bearings | Requires Continuous Oil Lubrication |

| Cast Bronze | High mechanical strength and load capacity, good thermal conductivity | Heavy machinery, hydraulic cylinder pivots, construction equipment | Requires Grease or Oil Lubrication |

4. Key Advantages: Why Choose Flanged Sleeve Bearings?

Engineers specify flanged sleeve bearings for a powerful combination of benefits that solve common mechanical design problems:

Handles Combined Loads: The primary advantage of the flanged design is its ability to support both radial loads (perpendicular to the shaft) and axial (thrust) loads (parallel to the shaft) simultaneously. This simplifies assembly by often eliminating the need for separate thrust washers or complex bearing housings.

Reduces Maintenance & Enables Dry Running: Many modern materials, like PTFE composites, are designed for maintenance-free or low-maintenance operation. They can run with initial lubrication or completely dry, making them ideal for sealed-for-life applications or environments where adding lubricant is impossible or undesirable.

Quieter and Smoother Operation: The sliding contact of a well-lubricated sleeve bearing is generally quieter than the rolling contact of ball bearings, especially at start-up. This is crucial for consumer appliances, office equipment, and medical devices.

Cost-Effective and Compact: Sleeve bearings are typically less expensive to manufacture than equivalent rolling-element bearings. Their simple, compact design also allows for lighter and smaller overall assemblies, saving space and material.

Excellent Shock Load Resistance: With a larger contact area than point contacts in ball bearings, sleeve bearings can absorb and distribute impact and vibration loads more effectively, protecting other sensitive components in the system.

5. Critical Applications Across Industries

The versatility of flanged sleeve bearings makes them indispensable in nearly every sector of engineering. They are particularly favored in applications where reliability, cost, and noise are key considerations.

Automotive & Transportation: Found in alternators, starter motors, power window assemblies, door hinges, and suspension joints. Their ability to handle vibration and shock is highly valued here.

Industrial Machinery & Automation: Used extensively in conveyor rollers, packaging machines, hydraulic cylinder mounts, and robotic joint pivots. Flanged bearings provide precise alignment and support for linear and rotary actuators.

Agricultural & Construction Equipment: Withstand high loads and contaminated environments in applications like tractor linkages, loader pivots, and gearbox supports. Sealed or self-lubricating versions prevent failure from dirt and moisture ingress.

Consumer Goods & Appliances: Essential for the quiet, reliable operation of washing machine drums, refrigerator compressors, treadmill rollers, and office furniture slides.

Aerospace & Specialized Applications: Used in flight control mechanisms, landing gear assemblies, and satellite components where extreme temperatures, vacuum conditions, or the need for maintenance-free operation are paramount.

6. Why Choose MYWAY Bushings for Your Next Project?

At MYWAY, we turn the advanced material science of sleeve bearings into reliable, high-performance solutions for our clients. Our expertise lies in engineering composite bushings that push the boundaries of what’s possible in machine design.

Innovative Material Design: We specialize in metal-polymer composites, crafting bushings with a steel backing for strength, a porous bronze interlayer for thermal management, and a proprietary polymer-based surface for unmatched low-friction performance. Our materials can operate effectively from cryogenic cold to high-heat environments without failure.

Engineered for Your Application: Whether you need a standard flanged bushing or a completely custom geometry—with special grooves, holes, or mounting features—our engineering team works with you to develop the optimal component. We solve problems related to load capacity, speed (PV limit), environmental exposure, and lifetime expectations.

Performance That Lowers Total Cost: A MYWAY bushing isn’t just a component purchase; it’s an investment in your machine’s future. By extending maintenance intervals, eliminating lubrication systems, reducing energy consumption through lower friction, and preventing unplanned downtime, our bushings deliver a lower total cost of ownership.

Trusted Across Industries: From precision components in semiconductor manufacturing equipment to heavy-duty bearings in maritime winches, MYWAY bushings are proven where reliability is non-negotiable.

7. Conclusion

If you are designing a new machine, troubleshooting a persistent failure, or simply seeking to improve reliability and reduce maintenance, the right flanged sleeve bearing is often the key. Contact MYWAY today for a consultation. Let our engineering team provide you with a sample, a custom quote, or an in-depth analysis of your application to help your designs move smoother, last longer, and perform better.

FAQ: Your Flanged Sleeve Bearing Questions Answered

Q1: What’s the difference between a sleeve bearing and a ball bearing?

A1: The core difference is in the motion. Sleeve bearings use sliding contact, offering a larger load area, quieter operation, and better shock absorption. Ball bearings use rolling contact (with balls or rollers), typically offering lower starting friction and higher precision at high speeds but often at a higher cost and noise level.

Q2: Can flanged sleeve bearings be used in underwater or washdown applications?

A2: Absolutely. With the right material choice, such as stainless steel-backed PTFE composites, flanged bearings are highly resistant to corrosion from water, steam, and many chemicals. Their self-lubricating nature means they perform reliably without grease that could wash out or contaminate the environment.

Q3: How do I select the right size and material for my application?

A3: Key factors are shaft size and tolerance, radial and axial load values, rotational or oscillating speed, operating temperature, and environmental conditions (presence of dirt, chemicals, etc.). Consulting with an application engineer, like those at MYWAY, is the best way to navigate these variables and select the optimal bearing.

Q4: Do all sleeve bearings require constant lubrication?

A4: No. This is a major advancement in bearing technology. Self-lubricating bearings made from oil-impregnated sintered metal or composites with solid lubricants like PTFE or graphite are designed to operate with initial lubrication only or completely dry. This makes them perfect for maintenance-free designs.

Q5: How can MYWAY help if I have a unique or failed application?

A5: We thrive on challenges. Our process starts with analyzing your specific needs—including why a previous bearing may have failed (e.g., wear, seizure, corrosion). Our engineers then leverage our material expertise and manufacturing capabilities to prototype and test a solution tailored to your exact operating conditions, ensuring performance and longevity.

100000+ Types of Bushings – Contact Us for Details