Recent Posts

Graphite as a Lubricant: The Dry Solution for Demanding Industries and Why MYWAY Excels

In the relentless world of industrial machinery, the battle against friction is constant and costly. Excessive wear, heat, and energy loss are the enemies of efficiency and profitability. While oils and greases have long been the standard soldiers in this fight, they come with drawbacks: attracting dirt, degrading under heat, and requiring constant reapplication. What if there was a cleaner, more resilient, and self-sufficient ally? Enter graphite—a naturally occurring mineral that is revolutionizing lubrication, especially within critical components like bushings and bearings. This article delves into the science of graphite lubrication and explains why MYWAY is your premier partner for integrating this technology into durable, high-performance solutions.

Table of Contents

1. The Molecular Magic: Why Graphite is a "Slippery" Superstar

At its core, graphite’s lubricating prowess isn’t magic; it’s pure materials science. Its structure is the key.

A Layered Lattice: Imagine a stack of perfectly flat honeycomb sheets, where each hexagon is made of carbon atoms. These sheets, or graphene layers, have incredibly strong bonds within the plane.

Weak Interlayer Forces: However, the bonds between these sheets are exceptionally weak (van der Waals forces). This structural dichotomy means the layers can slide over one another with minimal effort when shear force is applied.

The Self-Lubricating Effect: In a mechanical component, these microscopic layers shear off and transfer to the mating surfaces (like a shaft and a bushing bore), creating a slick, dry, protective film that reduces metal-to-metal contact. This process continuously renews itself from within the material, providing long-lasting dry lubrication.

2. Graphite vs. Conventional Lubricants: A Clear-Cut Advantage

Choosing graphite over traditional oils or greases isn’t just an alternative; it’s often a strategic upgrade. Here’s a detailed comparison:

| Feature | Graphite (Dry/Solid Lubricant) | Oil/Grease (Liquid Lubricant) |

|---|---|---|

| Lubrication Mechanism | Forms a dry, sliding film; self-lubricating from within a composite. | Creates a viscous fluid film between surfaces. |

| Temperature Range | Excellent. Effective from cryogenic to over 450°C (842°F) in air, and even higher in inert atmospheres. | Poor. Oils oxidize and break down; greases can melt or harden. Limited typically to -40°C to 180°C. |

| Cleanliness | Superior. No sticky residue. Does not attract dust, dirt, or debris, preventing abrasive paste formation. | Problematic. Acts as a “dust magnet,” leading to contamination and abrasive wear. |

| Maintenance Need | Very Low. Embedded graphite plugs act as reservoirs for the life of the part. No re-lubrication schedules. | High. Requires regular re-application, monitoring, and potential disposal of used lubricant. |

| Environmental Impact | Inert & Stable. Chemically inert; no risk of leak pollution. Graphite plugs are contained within the part. | Potential Hazard. Risk of spills, leaks, and environmental contamination. Requires careful handling and disposal. |

| Performance in Harsh Conditions | Exceptional. Works in vacuums (when paired with other materials like MoS2), dusty/dirty environments, and where chemical splashes occur. | Poor. Can wash away, evaporate, or react chemically. |

This comparison makes it clear: for demanding, high-temperature, low-maintenance, or clean applications, graphite-based lubrication is not just an option—it’s the optimal choice.

Industries worldwide leverage graphite’s unique properties to solve persistent friction problems:

High-Temperature Operations: In furnace conveyor systems, kiln cars, and metal processing equipment, where temperatures would cook conventional grease into carbon, graphite-lubricated components thrive.

Food & Pharmaceutical Processing: The dry, non-toxic, and contaminant-free nature of graphite makes it ideal for bushings in mixers, fillers, and packaging machines, meeting strict hygiene standards (H1 regulations where applicable).

Mining & Heavy Machinery: In extremely dirty and dusty environments (crushers, screens, excavators), graphite doesn’t trap abrasive particles, dramatically extending component life.

Aerospace & Vacuum Applications: Certain graphite formulations function in the dry, cold vacuum of space, where liquid lubricants would evaporate or outgas.

Applications Where Lubrication is Forgotten or Impossible: Components in sealed-for-life assemblies or in hard-to-reach locations benefit immensely from the “set-and-forget” reliability of embedded graphite.

4. The MYWAY Advantage: Engineering Graphite into Superior Bushing Solutions

Understanding the “why” behind graphite is one thing. Engineering it effectively into a reliable, high-load component is another. This is where MYWAY’s expertise transforms a great material into a superior product.

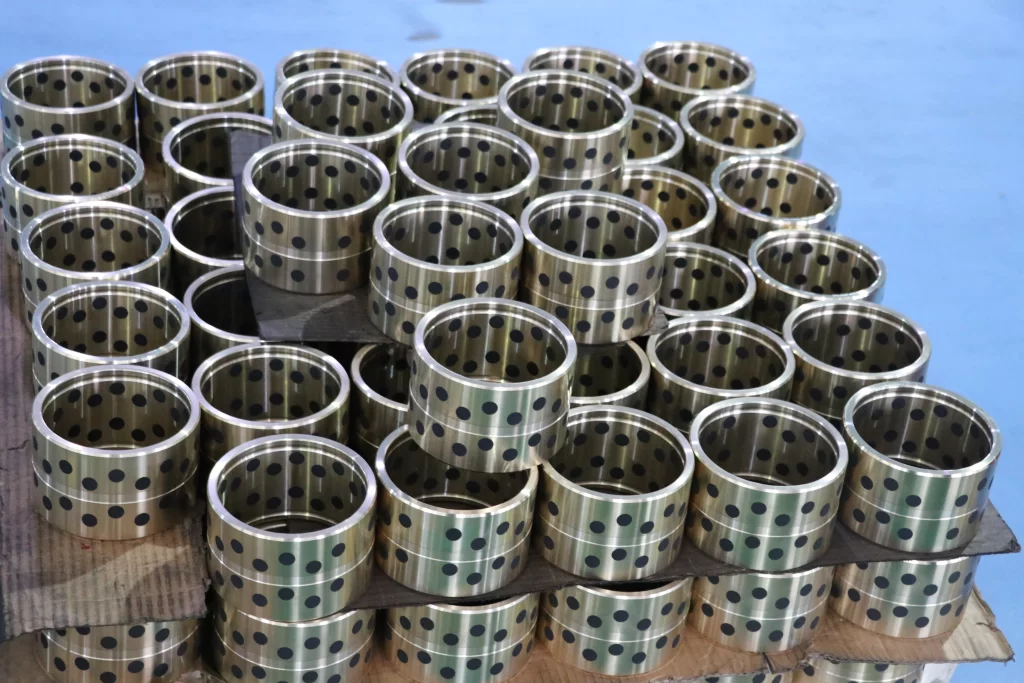

While many suppliers offer “graphite-impregnated” parts, MYWAY focuses on engineered composite solutions where graphite is a key player in a system designed for performance. Our approach includes:

Optimized Material Synergy: We don’t just add graphite powder to bronze. We engineer composites, often utilizing a robust steel or bronze backing for structural strength and load capacity, combined with a sintered porous layer that securely holds a proprietary blend of graphite and other solid lubricants like PTFE. This creates a part with high mechanical strength and a consistent, self-renewing lubricating surface.

Application-Specific Design: We understand that a bushing in a slow-oscillating, high-load excavator joint has different needs than one in a high-speed, high-temperature dryer section. Our engineering team can tailor:

The base material (high-strength bronze, steel, stainless steel for corrosion).

The lubricant mix ratio (graphite for high heat, PTFE for low friction and corrosion resistance, or a blend).

The plug pattern and density to ensure optimal lubricant distribution for the specific wear pattern.

The Smart Choice for Total Cost of Ownership (TCO): The initial cost of a high-quality, self-lubricating bushing is quickly offset by the elimination of:

Lubricant Purchase & Inventory Costs

Labor for Frequent Re-lubrication

Downtime for Maintenance

Premature Failure due to lubrication starvation or contamination.

Investing in MYWAY’s graphite-based solutions is an investment in predictable performance and reduced operational overhead.

5. Conclusion: Partner with the Experts in Dry Lubrication Technology

Graphite is more than just a lubricant; it’s a paradigm shift for designing reliable, low-maintenance machinery. However, its success hinges on expert integration into precision-engineered components.

MYWAY doesn’t just sell bushings with graphite in them. We provide engineered friction solutions. By combining deep material science knowledge with precision manufacturing and a client-centric design approach, we ensure that the theoretical benefits of graphite lubrication are fully realized in your application—reducing your downtime, maintenance costs, and total cost of ownership.

Frequently Asked Questions (FAQ)

Q1: Is graphite lubrication better than PTFE (Teflon) lubrication?

Both are excellent dry lubricants with different strengths. Graphite excels in high-temperature, high-load applications and is electrically conductive. PTFE offers an even lower coefficient of friction at lower temperatures and is superior in wet, acidic, or highly corrosive environments where graphite might promote galvanic corrosion. At MYWAY, we often use blends or select the optimal material based on your specific operating conditions.

Q2: I’ve heard graphite can cause galvanic corrosion. Is this true?

Yes, this is a critical consideration. Pure graphite is electrically conductive and can promote electrolytic (galvanic) corrosion when in contact with dissimilar metals in the presence of an electrolyte (like water or humidity). MYWAY’s engineered composites mitigate this risk by using the graphite within an insulating matrix or by recommending alternative materials like PTFE-based plugs for applications in submerged equipment or high-humidity atmospheres.

Q3: How long does the graphite lubrication last in a bushing?

In a properly designed and manufactured component like a MYWAY bushing, the graphite or solid lubricant plugs are reservoirs. They are designed to slowly and consistently transfer lubricant to the sliding surface over the entire intended service life of the part. The lifespan depends on load, speed, and alignment, but it far exceeds the interval of any re-greasing schedule.

Q4: Can I add grease to a graphite-impregnated bushing to “help” it?

No, this is strongly discouraged. Adding grease or oil to a self-lubricating bushing can actually hinder its performance. The liquid lubricant can clog the porous structure, preventing the graphite from transferring to the surface. More critically, it will attract dirt and grit, creating an abrasive paste that accelerates wear. The best practice is to keep self-lubricating components clean and dry.

Q5: What information do I need to provide to get a quote for a custom graphite-lubricated bushing?

To provide you with the most accurate solution and quotation, please share:

Application: (e.g., pivot joint on an excavator, conveyor roller in a kiln).

Operating Conditions: Temperature range, presence of dirt/chemicals/water, load (radial and axial), and motion (rotation, oscillation).

Dimensions: Shaft diameter, required bushing length, and housing bore dimensions.

Quantity: Estimated annual usage or project volume.

100000+ Types of Bushings – Contact Us for Details