Recent Posts

Precision in Motion: How Bronze CNC Machining Defines MYWAY Bushing

At the heart of every MYWAY Bushing lies a commitment to excellence through advanced Bronze CNC Machining. This process combines the timeless durability of bronze alloys with cutting-edge manufacturing technology to produce high-performance bushings tailored for demanding applications. In this article, we explore how precision machining elevates bushing performance, the materials we use, and the advantages of partnering with MYWAY.

Table of Contents

1. What is Bronze CNC Machining?

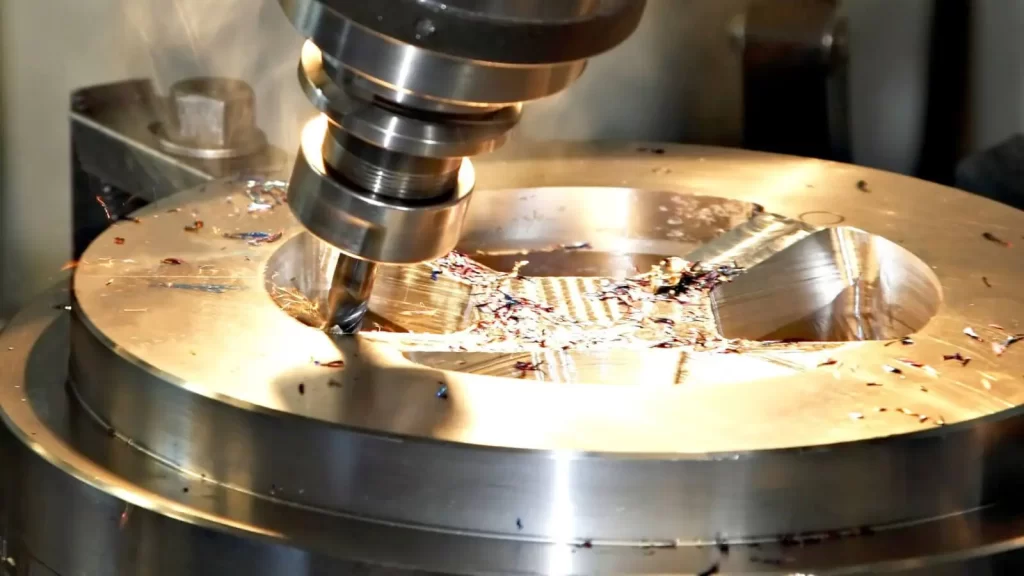

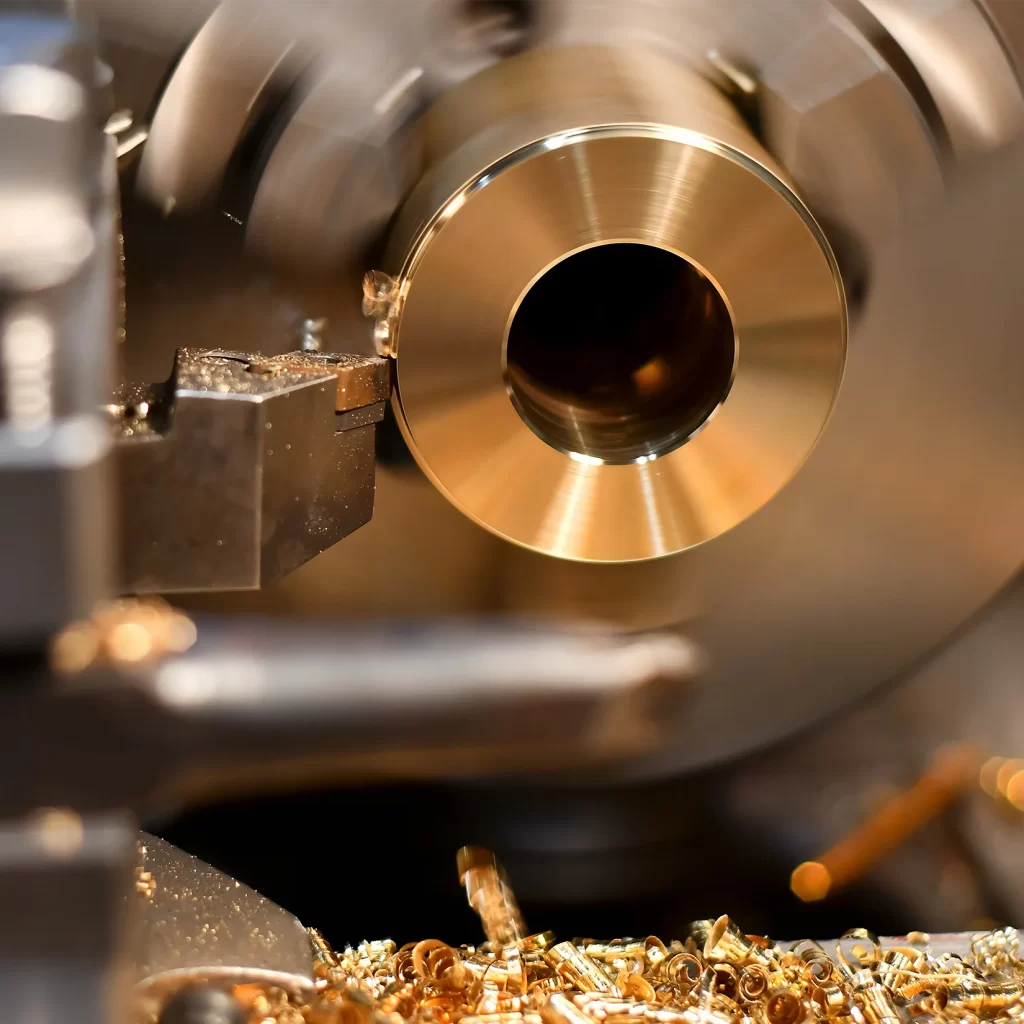

Bronze CNC Machining is a subtractive manufacturing process where computer-controlled equipment precisely removes material from bronze blocks to create complex components. This CNC bronze fabrication technique enables us to produce bushings with exceptional dimensional accuracy and surface quality. The machining bronze process transforms raw bronze alloy into high-performance components through systematic material removal.

2. The Role of Bronze in Bushing Manufacturing

Bronze alloys are the material of choice for high-quality bushings due to their exceptional properties:

Wear Resistance: Bronze withstands friction and abrasive conditions, ensuring long component life.

Corrosion Resistance: Ideal for marine, chemical, and outdoor applications.

Self-Lubricating Properties: Alloys like leaded tin bronze (C93200/SAE 660) reduce the need for frequent maintenance.

Thermal Conductivity: Dissipates heat efficiently, preventing deformation under high loads.

At MYWAY, we use premium bronze materials, including C954 Aluminum Bronze for heavy-duty applications and C510 Phosphor Bronze for components requiring fatigue resistance. Each alloy is selected to align with operational demands, ensuring reliability and longevity.

3. Precision CNC Machining: The MYWAY Process

Our CNC machining process transforms raw bronze into precision bushings with tight tolerances and superior surface finishes. Key steps include:

Digital Design & Simulation: CAD models are optimized for functionality and manufacturability.

Toolpath Optimization: CAM programming ensures efficient material removal and minimal tool wear.

High-Accuracy Machining: Multi-axis CNC mills and lathes create complex geometries with micron-level precision.

Quality Assurance: Every bushing undergoes rigorous inspections using CMMs and surface roughness testers.

We address common machining challenges, such as work hardening and chip control, through specialized tool coatings (e.g., TiAlN) and adaptive machining strategies.

Our CNC-machined bushings serve critical roles across industries:

Heavy Machinery: Excavator track rollers, pivot joints, and hydraulic cylinders.

Marine Systems: Propeller shafts, rudder bearings, and seawater pump components.

Automotive Engineering: Engine bushings, transmission parts, and suspension components.

Aerospace: Landing gear bearings and hydraulic manifold blocks.

5. Why Choose MYWAY?

Customization: Tailored solutions for dimensions, alloys, and surface treatments.

Advanced Technology: State-of-the-art CNC equipment and tooling.

Quality Focus: Compliance with international standards (e.g., DIN ISO 3547, SAE 792).

6. FAQs About Bronze CNC Machining and Bushings

What bronze alloys are best for bushings in high-load environments?

C954 Aluminum Bronze offers exceptional strength and corrosion resistance, while C932 Bearing Bronze provides superior self-lubrication for moderate loads.

How does CNC machining improve bushing performance?

Precision machining ensures optimal dimensional accuracy, surface finish, and material integrity, reducing wear and extending service life.

Can MYWAY customize bushings for specific applications?

Yes! We tailor bushings to your requirements, including material grade, lubrication features, and dimensional tolerances.

What post-processing options are available?

We offer polishing, bead blasting, heat treatment, and anti-corrosion coatings to enhance functionality and aesthetics.

How do I maintain bronze bushings?

While self-lubricating alloys reduce maintenance, periodic lubrication (grease or oil) can further extend lifespan in high-stress applications.

Unlock the potential of precision-engineered bronze bushings for your machinery. Contact MYWAY today to discuss your project requirements or request a custom quote!

10000+ Types of CNC Bushings – Contact Us for Details