Recent Posts

How to Replace and Install the Control Arm Bushings?

Introduction: Understanding Control Arm Bushings

Control arm bushings are crucial components in your vehicle’s suspension system that serve as flexible connections between the control arms and the vehicle frame. These rubber or polyurethane components absorb road shocks, reduce vibrations, and allow for controlled movement of the suspension while maintaining proper wheel alignment. When these bushings wear out, they can significantly impact your vehicle’s handling, safety, and comfort.

Table of Contents

1. Recognizing the Symptoms of Worn Control Arm Bushings

Audible Warning Signs

One of the first indicators of failing control arm bushings is unusual noises. Drivers often report:

Clunking or popping sounds when going over bumps or during acceleration and braking

Creaking or groaning noises at low speeds, particularly when turning or navigating speed bumps

Knocking sounds from the suspension during sharp turns or sudden maneuvers

Handling and Performance Issues

As bushings deteriorate, you may notice:

Loose or wandering steering requiring constant correction

Steering wheel vibration that transmits through to your hands

Vehicle instability during braking, often accompanied by pulling to one side

Reduced handling precision and increased body roll during cornering

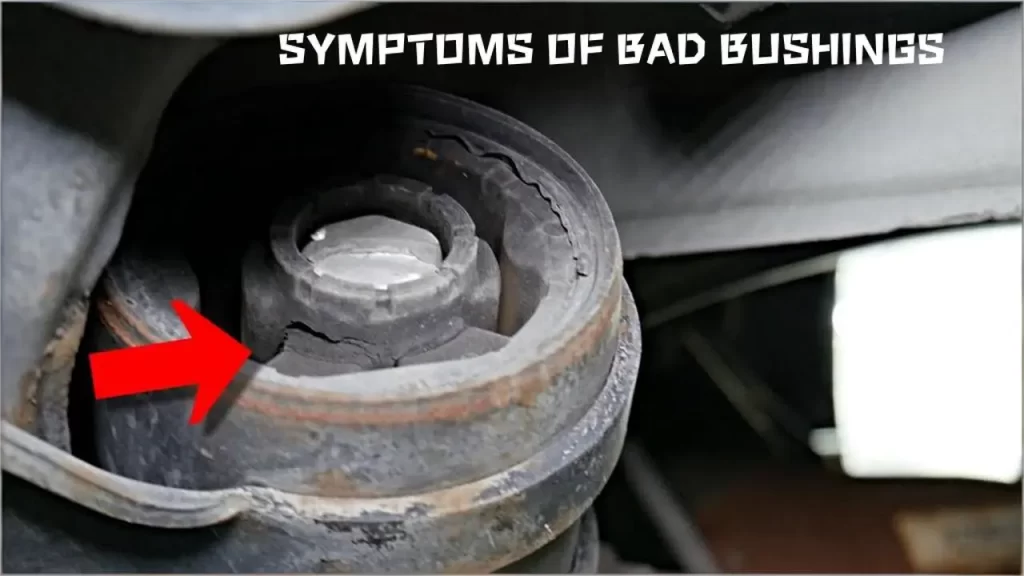

Visible Indicators

Physical inspection can reveal:

Uneven tire wear patterns indicating alignment issues

Cracked, torn, or missing rubber components in the bushing

Fluid leakage from hydraulic bushings in some vehicles

Misalignment of the inner metal sleeve within the bushing

2. Diagnostic Procedures: Confirming Bushing Failure

Visual Inspection Techniques

Conduct a thorough visual examination by:

Safely lifting the vehicle and supporting it with jack stands

Cleaning the control arm and bushing area for clear visibility

Using a flashlight to inspect for cracks, separation, or deformation

Checking for rust or corrosion around bushing mounting points

Physical Testing Methods

Pry Bar Test: Carefully insert a pry bar between the control arm and frame, applying gentle pressure to check for excessive movement

Wheel Shake Test: With the vehicle elevated, grasp the tire at 3 and 9 o’clock positions, rocking it to detect play

Bushing Twist Test: Observe if the bushing twists excessively during suspension movement

3. Replacement Considerations: Bushing vs. Complete Control Arm

When to Replace Only the Bushings

Bushing-only replacement may be appropriate when:

The control arm itself is in good condition without rust or damage

The vehicle design allows for separate bushing replacement

Budget constraints make this the more economical choice

Performing restoration work on classic or specialty vehicles

Advantages of Complete Control Arm Assembly Replacement

Modern repair strategies often favor complete control arm replacement because:

Time efficiency: Most mechanics can replace an entire assembly faster than pressing individual bushings

Comprehensive repair: Includes new ball joints that often wear simultaneously with bushings

Reduced labor costs: Fewer workshop hours can offset the higher parts cost

Warranty coverage: Complete assemblies often come with better warranty protection

4. Professional Replacement Process: Step-by-Step

Preparation and Safety Measures

Vehicle Securing: Park on level ground, engage parking brake, and place wheel chocks

Proper Lifting: Use a quality floor jack and support with jack stands rated for the vehicle weight

Personal Protective Equipment: Wear safety glasses and gloves throughout the process

Control Arm Removal Procedure

Wheel Removal: Loosen lug nuts before lifting, then remove wheels completely

Component Disconnection:

Separate ball joint from steering knuckle using appropriate tools

Disconnect sway bar links if necessary

Remove stabilizer bar connections

Control Arm Unbolting:

Note bolt orientation for reassembly

Use penetrating oil on corroded fasteners

Support the control arm during final bolt removal

Bushing Replacement Techniques

Pressing Out Old Bushings:

Use a hydraulic press or specialized bushing removal tools

Support the control arm properly to prevent damage

Apply steady, even pressure to avoid distortion

Installing New Bushings:

Ensure correct orientation according to manufacturer specifications

Use appropriate adapters to press evenly on the outer sleeve

Verify the bushing is seated completely and squarely

Reassembly and Final Steps

Control Arm Reinstallation:

Position the control arm correctly

Install bolts hand-tight initially

Component Reconnection:

Reattach ball joints and other suspension components

Replace any stretch bolts or specific fasteners as required

Final Torquing:

Tighten all fasteners to manufacturer specifications

Critical: Final bushing bolts must be tightened with the vehicle at normal ride height

5. Post-Installation Requirements

Wheel Alignment

A professional wheel alignment is absolutely essential after any control arm or bushing replacement. Failure to align properly will result in:

Rapid, uneven tire wear

Poor vehicle handling

Reduced fuel efficiency

Potential safety hazards

Test Drive and Inspection

After completion:

Conduct a careful test drive at low speeds initially

Listen for unusual noises

Verify proper handling characteristics

Re-check torque specifications after 50-100 miles

6. DIY vs. Professional Service: Making the Right Choice

DIY Replacement Considerations

While possible for experienced home mechanics, DIY bushing replacement presents challenges:

Specialized tool requirements: Hydraulic presses or bushing tools are necessary

Technical knowledge: Understanding torque specifications and procedures is crucial

Safety concerns: Working with suspension components carries inherent risks

Time investment: The process typically takes 3-5 hours per side for inexperienced mechanics

Benefits of Professional Service

Proper equipment: Shops have presses, alignment machines, and experienced technicians

Efficiency: Professionals typically complete the job in 2-3 hours per side

Warranty protection: Most shops guarantee their work

Comprehensive inspection: Professionals can identify related issues needing attention

At MYWAY, we engineer our control arm bushings to exceed OEM specifications, providing:

Advanced Material Technology

Premium rubber compounds resistant to heat, ozone, and environmental degradation

Precision molding for consistent performance and perfect fitment

Optimized design for reduced vibration transmission and improved comfort

Application-Specific Solutions

MYWAY offers comprehensive bushing solutions for:

Passenger vehicles from compact cars to full-size SUVs

Performance applications with enhanced handling characteristics

Commercial vehicles requiring heavy-duty durability

Custom solutions for specialty and restoration projects

Quality Assurance

Every MYWAY bushing undergoes rigorous testing for:

Load capacity and durability under extreme conditions

Environmental resistance to temperature extremes and contaminants

Long-term performance through accelerated life cycle testing

8. Cost Analysis: Understanding Your Investment

Parts Cost Breakdown

Individual bushings: $20-$80 each depending on vehicle and bushing type

Complete control arms: $100-$400 per side including new bushings and ball joints

MYWAY solutions: Competitively priced with superior performance characteristics

Labor Cost Considerations

Professional installation: 2-3 hours labor per side at $80-$150 per hour

Wheel alignment: $100-$200 depending on vehicle and shop

Total investment: $300-$1,200 for most vehicles depending on repair approach

9. Conclusion: Ensuring Safety and Performance

Control arm bushing replacement is a critical maintenance procedure that directly impacts your vehicle’s safety, handling, and comfort. Whether you choose to replace individual bushings or complete control arm assemblies, using quality components like MYWAY bushings ensures long-lasting performance and reliability.

For severe bushing wear or when replacing multiple suspension components, consider professional installation to guarantee proper procedure adherence and alignment. Remember that timely bushing replacement protects your investment in tires and other suspension components while maintaining the safe operation of your vehicle.

Explore MYWAY’s complete range of suspension solutions designed to restore and enhance your vehicle’s performance. Our technical support team is available to help select the ideal bushing solution for your specific vehicle and driving requirements.

Visit our product catalog or contact our technical specialists for personalized assistance with your suspension repair needs.

10 Frequently Asked Questions (FAQ)

How long do control arm bushings typically last?

Control arm bushing lifespan varies by vehicle type, driving conditions, and material quality. Most OEM rubber bushings last 60,000-100,000 miles, while premium aftermarket solutions like MYWAY bushings can extend this interval significantly. Harsh driving conditions, extreme climates, and poor road quality can accelerate wear.

Can I replace just one control arm bushing, or should I do both sides?

While it’s possible to replace only the failed bushing, we strongly recommend replacing both sides simultaneously. When one bushing fails, the opposite side has typically experienced similar stress and is likely near failure. Replacing both ensures balanced handling and prevents a return visit for the same repair.

What's the difference between rubber and polyurethane bushings?

Rubber bushings provide excellent vibration damping and quiet operation, making them ideal for daily driving. Polyurethane bushings offer increased stiffness for improved handling response but may transmit more road noise. MYWAY offers both material types to match your specific driving needs and preferences.

How urgent is control arm bushing replacement?

Worn control arm bushings should be addressed promptly. While not an immediate emergency in early stages, significantly worn bushings compromise vehicle stability, braking performance, and tire wear. We recommend replacement within 1,000 miles of diagnosis to prevent secondary damage and maintain safety.

Will replacing control arm bushings improve my vehicle's ride quality?

Yes, replacing worn bushings typically restores original ride quality by eliminating excess suspension movement, reducing noise and vibration, and improving steering precision. Many customers report their vehicle feels “like new” after bushing replacement with quality components like MYWAY products.

What makes MYWAY bushings superior to other aftermarket options?

MYWAY bushings feature advanced compound formulations, precision manufacturing tolerances, and rigorous quality control. Our bushings are engineered to provide optimal balance between comfort and performance, with enhanced durability characteristics that outperform standard replacement parts.

100000+ Types of Bushings – Contact Us for Details