Recent Posts

Plastic Bushings: Maintenance-Free, Cost-Effective Performance

For engineers and procurement specialists navigating the complex world of industrial components, the quest for reliability, efficiency, and cost savings is never-ending. In the realm of motion and support, a quiet revolution has been taking place. Plastic bearing bushings are increasingly becoming the go-to solution, displacing traditional metal counterparts in a wide array of applications. From the food processing line that demands absolute cleanliness to the agricultural machinery battling mud and corrosion, these innovative components offer a compelling blend of performance and practicality.

This article delves deep into the world of plastic bushings. We’ll explore what they are, their undeniable advantages, the key materials that make them tick, and how to select the right one for your project. Finally, we’ll introduce you to how MYWAY Bushing, a leader in precision manufacturing, can be your ideal partner in leveraging this technology.

Table of Contents

1. Understanding Plastic Bearing Bushings: More Than Just a "Plastic Part"

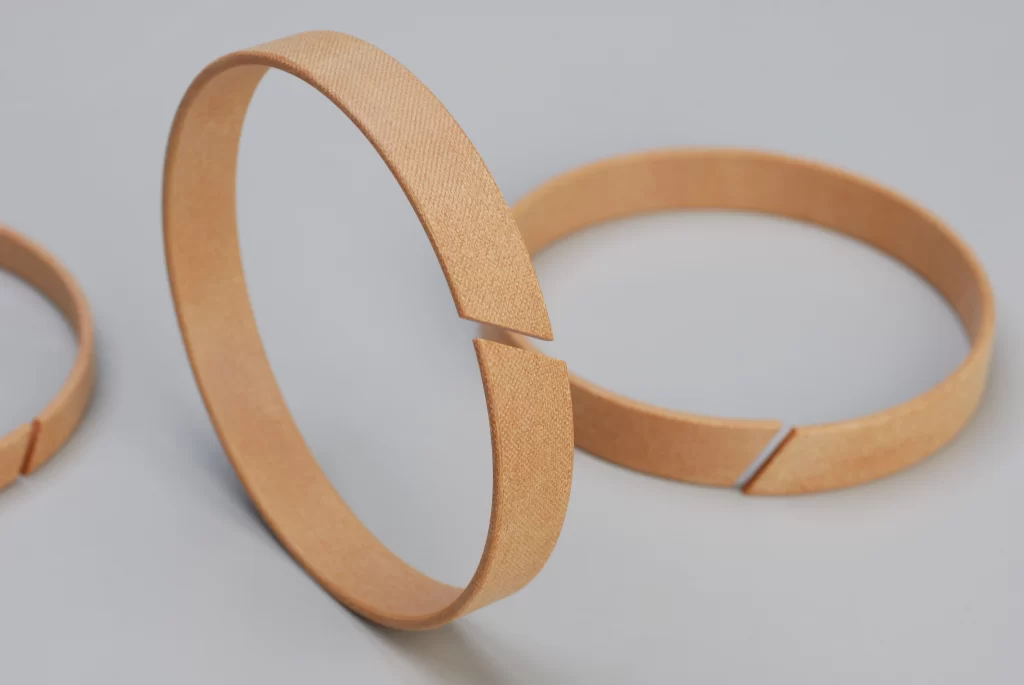

At its core, a plastic bearing bushing (also commonly called a plain bearing, sleeve bearing, or slide bearing) is a simple yet critical component. It’s designed to support a rotating or sliding shaft, providing a smooth, low-friction surface while reducing wear, vibration, and noise.

The fundamental difference from traditional bronze or steel bushings lies in its construction and inherent properties. Modern plastic bushings are engineered from high-performance polymers, often infused with special lubricants, fibers (like glass or carbon), and reinforcing fillers. This advanced material science transforms simple plastics into robust, self-lubricating bearings capable of outperforming metals in many scenarios.

2. Why Choose Plastic? The Unbeatable Advantages

The shift towards plastic bushing bearings is driven by tangible benefits that directly impact the bottom line and operational efficiency.

Maintenance-Free & Self-Lubricating: This is arguably the biggest advantage. Materials like PTFE (Teflon), Nylon (PA), and POM (Acetal) are inherently slippery or are compounded with solid lubricants. They eliminate the need for periodic greasing, saving on maintenance labor, downtime, and contamination risk—crucial for food-grade, pharmaceutical, or cleanroom applications.

Superior Corrosion Resistance: Unlike metal bearings that rust and pit, plastic bearings are virtually impervious to water, chemicals, acids, and alkalis. This makes them perfect for harsh environments like chemical processing, marine applications, washdown areas in packaging, and agricultural machinery.

Lightweight & Cost-Effective: Plastic is significantly lighter than metal, contributing to reduced overall machine weight and energy consumption. The injection molding manufacturing process also allows for high-volume production of complex shapes at a lower cost per unit compared to machining metal parts.

Excellent Wear Resistance & Quiet Operation: Engineered polymers offer outstanding wear resistance, often outlasting metals in dirty, dusty, or dry-running conditions. They also dampen vibration and operate almost silently, a key benefit for office equipment, medical devices, and consumer appliances.

Cleanliness & Compatibility: They generate no metallic dust and do not require oil, which can attract dirt or degrade products. This ensures a cleaner operation and makes them ideal for sensitive environments.

3. The Big Four: Common Materials for Plastic Bearings

Selecting the right material is paramount to success. Here are the four most common plastic bearing materials, each with its superpower:

POM (Polyoxymethylene / Acetal): Known for its high stiffness, excellent dimensional stability, and low friction against steel. It’s a great, cost-effective all-rounder for light to medium loads and offers good mechanical strength. Think of it as the reliable workhorse for conveyor rollers, gears, and general machinery.

Nylon (PA 6 / PA 66): Valued for its toughness, good wear resistance, and slightly higher temperature tolerance (up to 120°C continuous use). It’s often modified with MoS2 (Molybdenum Disulfide) or other additives to enhance its self-lubricating properties. Commonly used in automotive components, pulleys, and textile machinery.

PTFE (Polytetrafluoroethylene / Teflon): The king of low friction and chemical resistance. It has the lowest coefficient of friction of any solid material and can withstand almost all chemicals. It’s typically used as a coating or filler within other materials (like in iglide® composites) for demanding, low-speed/high-load, or highly corrosive applications.

UHMW-PE (Ultra-High Molecular Weight Polyethylene): An outstanding material for high wear resistance and impact strength, especially in wet or abrasive environments. It’s very resistant to cracking and is a top choice for material handling equipment, agricultural guides, and marine applications.

Comparison Table: Key Plastic Bushing Materials

| Material | Best For | Key Strength | Typical Limit |

|---|---|---|---|

| POM / Acetal | Precision parts, dry running, cost-sensitive apps | High rigidity, dimensional stability, low friction | Lower temp resistance (~100°C) |

| Nylon (PA) | Tough environments, moderate temps, light lubrication | Good toughness, wear resistance, dampens noise | Can absorb moisture affecting dimensions |

| PTFE-based | Extreme chemical resistance, ultra-low friction | Best chemical & temp resistance, no-stick surface | Lower mechanical strength, higher cost |

| UHMW-PE | Abrasive/wet environments, high impact | Excellent wear & impact resistance, very low moisture absorption | Lower maximum service temperature |

4. From Fields to Factories: Where Plastic Bushings Excel

The application list is vast and growing:

Agricultural Machinery: Sprayers, harvesters, and planters benefit from their corrosion resistance against fertilizer and mud.

Food & Beverage Conveying: Their maintenance-free and FDA-compliant nature ensures hygiene and prevents product contamination.

Automotive & Transportation: Used in seat adjusters, pedal boxes, and linkage systems for quiet operation and weight reduction.

Packaging & Printing Machinery: Their precision and low-friction enable high speeds and accurate registration.

Electrical Enclosures & Outdoor Uses: Excellent insulation properties and resistance to weathering.

5. Choosing the Right Partner: It's Not Just About the Plastic

While the material science is critical, the manufacturer’s expertise determines real-world performance. A perfect bushing design can fail due to poor tolerances, inconsistent material quality, or a lack of application understanding.

This is where MYWAY Bushing stands apart.

As a leading professional plain bearings manufacturer in China with a proven track record of supplying global giants like XCMG, SANY, and GWM, MYWAY brings a depth of engineering rigor to the plastic bushing space. We understand that a bearing is a system component, not just a commodity.

Why source your Plastic Bearing Bushings from MYWAY?

Deep Material Mastery: We don’t just sell generic plastics. Our engineering team helps you select and customize the optimal polymer compound—whether it’s a standard Nylon or a glass-filled POM for extra stiffness—to match your specific load, speed, and environmental conditions (temperature, chemicals, UV exposure).

Precision Manufacturing Heritage: Our core competency is manufacturing high-precision, heavy-duty metal bushings and sleeves. We apply the same stringent quality control, ISO-aligned processes, and tolerance expertise to our plastic line. You get a component that fits right the first time, every time.

Full-Service Support, From Prototype to Volume: From initial design consultation and rapid prototyping to stable, high-volume production, we provide a seamless partnership. Our integrated foundry and machining capabilities mean full control over quality and supply chain reliability.

A Partner You Can Trust: Our philosophy—”Quality is our lifeline, credibility drives our growth”—isn’t a slogan. It’s reflected in our sustained growth and the trust placed in us by industry leaders. We translate that same commitment to every plastic bushing order.

Ready to experience the MYWAY difference? Don’t let component wear, corrosion, or excessive maintenance slow down your operations.

👉 Contact the MYWAY team today for a competitive quote or a free technical consultation. Let our experts help you identify whether a high-performance plastic bushing is the optimal solution for your application, and provide you with a sample to test.

FAQ: Plastic Bearing Bushings

Q1: Can plastic bushings really handle heavy loads?

A: Yes, but with careful selection. While not typically for extreme heavy loads like large steel mills, reinforced plastics like glass-filled Nylon or POM can handle significant dynamic and static loads. The key is calculating the surface pressure (P) and velocity (V) to stay within the material’s PV limit. For very high loads, PTFE-based composites or our specialized metal-polymer hybrids might be recommended.

Q2: What is the maximum temperature for plastic bushings?

A: It varies by material. Standard POM and Nylon are generally safe up to 100-120°C. Special high-temperature PTFE formulations can operate continuously above 200°C, and PI (Polyimide) can even exceed 260°C. Always consult the specific material datasheet or our engineers.

Q3: Are plastic bushings suitable for high-speed applications?

A: They can be, but speed, load, and heat dissipation must be balanced. At very high speeds, frictional heat can build up. Materials with good thermal conductivity (often achieved with special fillers) and sometimes minimal initial lubrication are used. For ultra-high speeds, ball bearings might still be preferable, but for many industrial speeds, plastic bushings excel.

Q4: How do I install plastic bushings? Do they need a press fit?

A: Most are designed for a light press-fit into a housing. The housing bore should be clean, smooth, and chamfered. Installation with an arbor press is ideal to avoid damage. A key advantage is that they often compensate for minor misalignments and are much more forgiving during installation than fragile bronze bushings.

Q5: Why should I choose MYWAY over a specialized plastic parts supplier?

A: MYWAY offers a unique cross-disciplinary advantage. Our extensive experience with the most demanding metal bearing applications in construction and automotive industries gives us an unparalleled understanding of tribology (the science of wear and friction) and real-world mechanical stresses. We don’t just sell plastic parts; we provide engineered bearing solutions. Whether your optimal path is a advanced polymer, a classic bronze, or a custom composite, we give you unbiased, application-focused advice to ensure your machine’s longevity and performance.

100000+ Types of Bushings – Contact Us for Details