Recent Posts

In the world of metals, flashy names like titanium or stainless steel often steal the spotlight. But down in the trenches—inside a roaring pump, on a salt-sprayed ship deck, or at the friction-heavy heart of heavy machinery—a quieter, more dependable hero is at work. This is the realm of silicon bronze.

More than just “another bronze,” silicon bronze is a high-performance copper alloy engineered to solve problems where others fail. It combines the best of many worlds: strength approaching that of steel, corrosion resistance that shames standard brass, and a natural talent for reducing friction and wear . For engineers and procurement specialists battling downtime, maintenance costs, and component failure, understanding this material isn’t just technical—it’s strategic.

This guide cuts through the data sheets to explain why silicon bronze, particularly in the form of precision bushings and bearings, should be your first call for demanding applications. We’ll end with a look at how MYWAY Silicon Bronze Bushings translate this material science into reliable performance for your business.

Table of Contents

1. What is Silicon Bronze? Beyond the Basic Chemistry

At its core, silicon bronze is a copper alloy where silicon (typically 1-4%) is the principal additive, often joined by elements like manganese, nickel, zinc, or iron for enhanced properties . This simple-sounding mix creates a profound transformation.

Think of it as copper hitting the gym. Pure copper is ductile and corrosion-resistant but relatively soft. The addition of silicon introduces a hard, wear-resistant phase within the matrix, significantly boosting tensile strength and hardness without completely sacrificing copper’s innate benefits . The result is an alloy that’s tough, durable, and exceptionally versatile.

Key Characteristics That Matter on the Shop Floor:

High Strength & Excellent Wear Resistance: With tensile strength often exceeding 500 MPa, it handles heavy loads and resists the adhesive wear (galling) that plagues softer metals under high pressure . This makes it a premier choice for high-load bushings and bearings.

Superior Corrosion Resistance: It laughs at environments that eat plain steel for breakfast. Silicon bronze forms a stable, protective patina, offering outstanding resistance to freshwater, seawater, and many industrial chemicals . This is why it’s a staple in marine hardware and chemical processing equipment.

Good Machinability & Weldability: Unlike some high-performance alloys that are a nightmare to fabricate, silicon bronze is designer-friendly. It can be readily machined, welded, and formed using common techniques, keeping manufacturing costs in check .

Non-Sparking & Non-Magnetic: This critical safety feature makes it indispensable in explosive atmospheres (like oil & gas platforms) and sensitive electronic environments.

Built-in Lubricity: The silicon content contributes to a naturally lower coefficient of friction compared to many steels or brasses. This means silicon bronze bushings can perform well in situations with boundary lubrication or even short periods of dry running.

2. Silicon Bronze vs. The Competition: Choosing the Right Tool

When selecting a material for a bushing, bearing, or wear component, the choice often comes down to three common copper alloys. Here’s the real-world breakdown:

| Feature | Silicon Bronze (e.g., C65620/QS-3-1) | Phosphor Bronze (e.g., C51000) | Common Brass (e.g., C36000) |

|---|---|---|---|

| Primary Strength | Balanced High Strength & Corrosion | Excellent Fatigue Resistance & Springiness | Excellent Machinability, Low Cost |

| Wear Resistance | Excellent | Good | Poor |

| Corrosion Resistance | Excellent (esp. vs. seawater) | Good | Fair (Prone to dezincification) |

| Best Use Case | High-load bushings, marine bearings, valve stems, pump parts. | Springs, electrical connectors, light-duty bearings. | Low-stress, non-corrosive fittings, decorative parts. |

The Verdict: For bushings and bearings that face a combination of high load, rotational/oscillating friction, and a corrosive or marine environment, silicon bronze isn’t just an option—it’s the optimal, cost-effective solution over the long term. Choosing cheaper brass here is a false economy, leading to premature failure and downtime.

3. Where Silicon Bronze Truly Shines: Real-World Applications

This isn’t theoretical. Silicon bronze components are hard at work across industries, proving their mettle:

Marine & Shipbuilding: The ultimate test. From rudder bearings and propeller shaft bushings to deck cleats and fasteners, silicon bronze withstands constant saltwater immersion where stainless steel might pit and plain brass would corrode away.

Heavy Machinery & Construction: In excavators, cranes, and presses, pivot bushings and linkage bearings endure immense shock loads and contamination. Silicon bronze’s strength and wear resistance ensure longevity.

Pumps, Valves, & Fluid Handling: As wear rings, shaft bushings, and valve stems, it handles aggressive fluids, abrasives, and high pressures while resisting chemical attack and seizure.

Aerospace & Defense: Chosen for landing gear components and other critical wear parts due to its reliable performance, non-sparking nature, and strength-to-weight ratio.

Industrial Manufacturing: Anywhere a high-load, low-speed bushing is needed on machinery, from steel mills to printing presses, silicon bronze provides a durable, maintenance-friendly solution.

4. Introducing MYWAY Silicon Bronze Bushings: Engineered for Demanding Duty

Understanding the material is the first step. Applying it correctly in a precisely engineered component is the next. That’s where MYWAY Bushings come in.

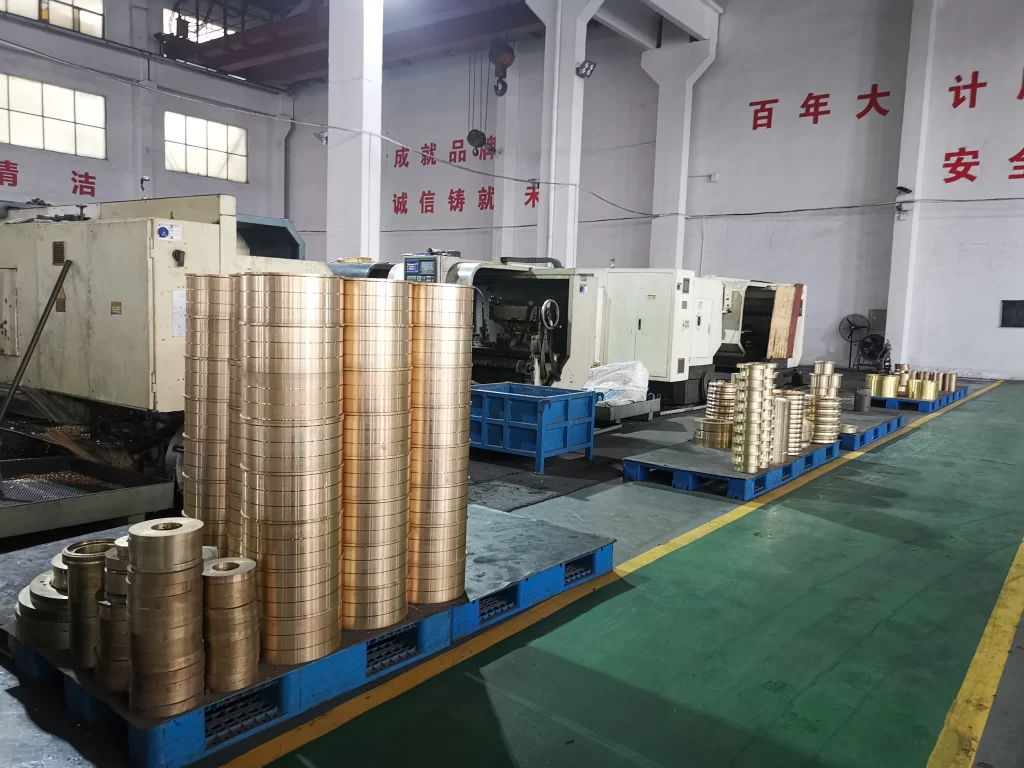

We don’t just sell metal; we sell reliability, reduced downtime, and cost savings. Our Silicon Bronze Bushings are manufactured from premium-grade alloys (conforming to standards like ASTM B98/C65620 or equivalent international specs like QSi3-1) to guarantee consistent, high-performance material properties in every piece .

Why Specify MYWAY Silicon Bronze Bushings?

- Optimized for High-Load Applications: Our bushings are designed with the inherent strength of silicon bronze in mind, making them perfect for replacing failing steel or brass bushings in high-stress points.

- Superior Wear Life: The excellent wear resistance of the material means longer service intervals, less frequent replacement, and lower long-term operating costs.

- Built for Harsh Environments: Whether it’s exposure to weather, seawater, or industrial chemicals, our bushings offer outstanding corrosion protection, ensuring functional integrity where others rust or corrode.

- Reduced Maintenance Needs: The natural lubricity of silicon bronze can reduce friction and galling, decreasing the dependency on perfect lubrication and allowing for smoother operation.

- Precision Manufacturing: We ensure tight tolerances, excellent surface finishes, and geometric accuracy for a perfect fit and optimal performance in your assembly.

From Material to Solution:

We provide standard and custom-sized silicon bronze bushings, flanged bushings, and thrust washers. Whether you’re in OEM design or MRO procurement, we can supply the right wear component to solve your specific challenge.

5. Ready to Upgrade to Unmatched Durability?

Stop compromising with materials that aren’t up to the task. When your application demands a combination of strength, corrosion resistance, and wear performance, the answer is clear: silicon bronze. And the most reliable source for precision-engineered silicon bronze components is MYWAY.

Let’s solve your toughest wear challenges together.

Contact us today for a quote, technical consultation, or samples. Tell us about your application, load requirements, and environmental conditions. Our team will help you specify the perfect MYWAY Silicon Bronze Bushing to extend service life, reduce maintenance, and keep your operations running smoothly.

Click here to send your inquiry now and experience the MYWAY difference in performance and reliability.

Frequently Asked Questions

Q: Is silicon bronze better than regular bronze for bushings?

A: For bushings facing high loads and wear, often yes. While traditional tin bronzes (like C93200) are excellent for general-purpose bearings, silicon bronze typically offers higher tensile strength and better corrosion resistance in seawater, making it a more robust choice for demanding applications .

Q: Can silicon bronze bushings be used in seawater?

A: Absolutely. This is one of its strongest suits. Silicon bronze has exceptional resistance to corrosion from both fresh and saltwater, making it a premier material for marine bushings, bearings, and fittings .

Q: How does the cost compare to steel or sintered bronze bushings?

A: Initial unit cost may be higher than standard steel or sintered oil-impregnated bronze. However, the total cost of ownership is often lower. Silicon bronze bushings last significantly longer in corrosive or high-wear settings, prevent damage to more expensive mating parts, and reduce unplanned downtime, offering substantial savings over time.

Q: Are MYWAY silicon bronze bushings ready to install?

A: Yes. Our bushings are supplied fully machined to your specified dimensions and tolerances, with a surface finish suitable for immediate installation and operation.

Q: Can you manufacture custom bushings from silicon bronze?

A: Yes, we specialize in custom solutions. We work with you to produce bushings, bearings, and wear parts to your exact drawings, whether it’s a unique flange design, a specific wall thickness, or a non-standard alloy variant.

Q: What industries do you typically supply?

A: We serve a wide range, including marine, shipbuilding, heavy equipment manufacturing, pump and valve OEMs, industrial machinery, and mining. Anywhere durable, corrosion-resistant wear components are critical.

100000+ Types of Bushings – Contact Us for Details