Recent Posts

At the heart of modern industry lies a technology that acts as a silent sculptor, transforming solid metal blocks into precise components. This technology is CNC Machining (Computer Numerical Control Machining). For high-performance products like MYWAY Bushings, CNC Machining is the very foundation of their superior performance and reliable quality.

Today, let’s explore how MYWAY Bushing leverages advanced CNC Machining technology to achieve its exceptional industrial performance.

Table of Contents

1. What is CNC Machining?

In simple terms, CNC Machining is a manufacturing process where pre-programmed computer software dictates the movement of industrial machine tools to automate production. The key differences from traditional manual machining are “digitalization” and “automation.”

At the MYWAY factory, the birth of every Bushing begins with a precise digital 3D model. This model is converted into a series of commands (called G-code) that guide CNC Machines—whether CNC Mills or CNC Lathes—in performing high-precision metalworking. The entire process is a perfect dance between digital commands and the physical world.

2. CNC Machining: Why is it the Preferred Choice for Precision Parts?

Why does MYWAY steadfastly choose CNC Machining to manufacture our Bushings? Because it perfectly aligns with our demanding quality standards:

- Unmatched Precision: The capabilities of Precision CNC Machining ensure that every MYWAY Bushing meets dimensional tolerances at the micrometer level. This extreme consistency is a prerequisite for achieving a perfect fit in complex assemblies.

- Excellent Repeatability: Whether your order is for 1 unit or 100,000 units, CNC Technology guarantees that each product is a perfect replica of the last. This stability is crucial for large-scale industrial production.

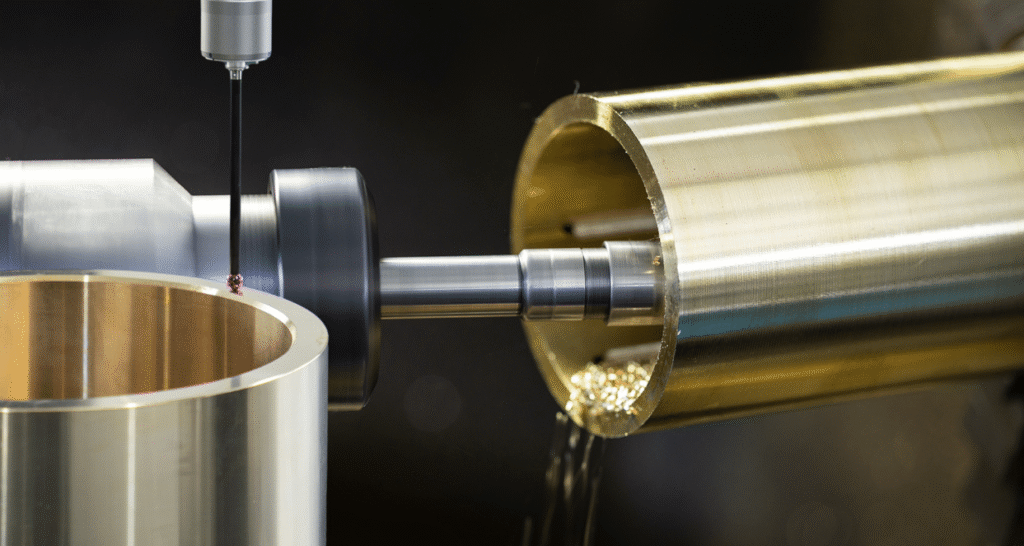

- Handling Complex Geometries: Features like oil grooves, mounting holes, and special contours on a Bushing can be easily achieved through CNC Milling and turning. Digital Manufacturing grants us the design freedom to optimize every detail for enhanced product performance.

- Superior Surface Integrity: By precisely controlling cutting parameters, the CNC Process delivers a smooth, uniform surface finish for MYWAY Bushings, thereby reducing friction and improving wear resistance and service life.

3. The Journey of a MYWAY Bushing: A CNC Machining Process

The creation of a MYWAY Bushing is a classic journey in Precision Manufacturing:

Step 1: Digital Design – Our engineers use professional software to design the optimal 3D model for the Bushing.

Step 2: Programming & Setup – A CAM Programming specialist converts the model into machining instructions understandable by the CNC Machine Tool, preparing the necessary fixtures and cutting tools for the Machining Center.

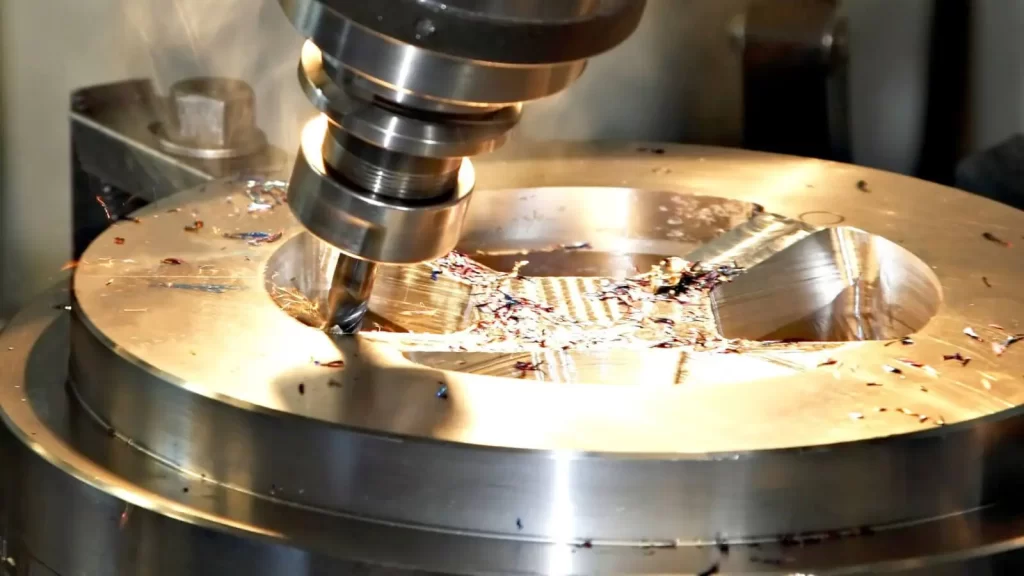

Step 3: Precision Cutting & Forming – A high-quality bronze or alloy steel blank is secured in the CNC Machine. Under computer control, high-speed rotating cutting tools begin the Material Removal process. Metal chips fly as the product’s form gradually emerges.

Step 4: Quality Inspection – The finished Bushing undergoes rigorous quality checks to ensure its dimensions, form, and surface finish fully comply with design standards.

It is this rigorous CNC Machining Solution that ensures every MYWAY Bushing leaving our factory carries our commitment to precision and reliability.

4. Beyond the Component: The Value Added by CNC Technology

Choosing a MYWAY Bushing manufactured via CNC Machining means you receive more than just a part; you receive a guarantee of value. It translates to lower failure rates, longer maintenance intervals, higher equipment operational efficiency, and a lower total cost of ownership. This is the core value of modern Smart Manufacturing and Precision Engineering.

5. Conclusion

At MYWAY, we regard CNC Machining as a philosophy, not just a process. It represents our commitment to delivering the best products to every customer through accurate, reliable, and innovative CNC Manufacturing technology. When you choose a MYWAY Bushing, you are choosing the exceptional quality supported by an entire advanced CNC Machining system.

10000+ Types of CNC Bushing – Contact Us for Details