Recent Posts

The Grease or No-Grease Debate: Getting Sway Bar Bushings Right

Few topics in DIY car maintenance spark as much debate as whether or not to grease sway bar bushings. One corner of the internet is filled with forum posts advising a quick spray of silicone lubricant to silence an annoying squeak. Another corner features strong warnings from seasoned engineers and parts manufacturers that grease is a recipe for long-term damage. So, who’s right?

This confusion often leads to a cycle of temporary fixes followed by premature part failure. This article cuts through the noise, explaining why the “grease or no-grease” question depends entirely on your bushing’s material, and how making the wrong choice can cost you more than just your sanity.

Table of Contents

1. The Core of the Controversy: Why Bushings Squeak

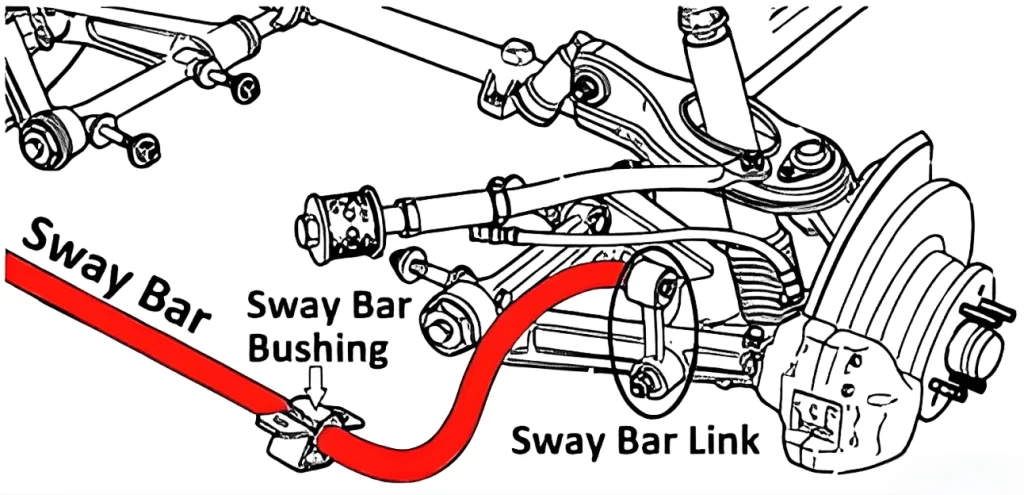

A sway bar (or anti-roll bar) is a critical suspension component that reduces body roll during cornering. It’s connected to the vehicle’s frame or subframe by two bushings, which allow it to twist. When these bushings are in good condition, this twisting happens smoothly and quietly. The classic low-pitched groan or creak over bumps occurs when there’s excessive dry friction between the bushing’s inner surface and the sway bar itself.

The instinct to reach for a lubricant is logical. In the short term, grease or silicone spray can indeed silence the noise by creating a slippery layer. However, this “fix” addresses the symptom, not the cause, and for many bushings, it inadvertently creates a bigger problem.

2. The Perils of the Quick Grease Fix: Real-World Lessons

Online automotive communities are archives of hard-earned experience. A recurring story involves a driver applying a general-purpose grease or silicone paste to quiet their rubber sway bar bushings, only to find the noise returns worse than before within weeks. One user shared that after applying silicone paste, they were left with an “annoying squeak” that wasn’t there before, suspecting the lube had created a glaze that caused the noise.

More critically, grease acts as a magnet for abrasive contaminants like dirt, dust, and road grit. A prominent suspension parts manufacturer, BajaRon, explicitly warns against this practice, noting that the grease-and-grit mixture forms an abrasive slurry that accelerates wear on both the bushing and the sway bar’s protective coating. Once the coating is worn through, the bar can rust, and the resulting increased clearance guarantees the clunking noise will return, necessitating the replacement of both the bar and bushings.

3. Material Matters: Rubber vs. Polyurethane

The lubrication debate has a simple, material-based answer:

| Material | Should You Grease? | Why? | Recommended Lubricant (if any) |

|---|---|---|---|

| OEM Rubber Bushings | No | Designed to grip the bar and twist with it. Grease allows the bar to slide inside the bushing, which can cause knocking, irregular handling, and rapid wear. | None. Clean the bar and bushing surface thoroughly. |

| Aftermarket Polyurethane Bushings | Yes | The firmer material has a higher coefficient of friction. They require lubrication during installation to prevent binding, squeaking, and excessive bushing deformation. | A dedicated polyurethane bushing grease (often white lithium-based). Avoid petroleum-based greases that can degrade the material. |

The Verdict on Rubber: For the factory rubber bushings found on most vehicles, the consensus among experienced mechanics is clear. As one forum member succinctly stated, “The best lube is no lube”. Noise from a rubber bushing is typically a sign of age, hardening, or incorrect installation torque, not a lack of grease. The proper fix is replacement with a high-quality, correctly sized new bushing.

4. The Correct Procedure: Replacement Over Lubrication

If your factory rubber bushings are squeaking, replacement is the definitive, long-term solution. Here’s a simplified overview of the process, which aligns with detailed DIY guides available for many specific models:

Safety First: Secure the vehicle on jack stands on a level surface.

Gain Access: You typically need to unbolt the sway bar end links and sometimes turn the steering wheel for clearance to access the bracket bolts holding the bushing.

Remove the Bracket: Unbolt the single retaining bracket, which may require some careful maneuvering to free a curved bottom tab.

Inspect and Replace: Remove the old, split bushing. Crucially, measure your sway bar diameter (common sizes are 21mm, 23mm, etc.) to ensure you get the correct replacement part.

Clean and Install: Thoroughly clean the section of the sway bar where the new bushing will sit. Lightly lubricate only the outside of the sway bar (not the bushing’s inner bore) with a water-based lubricant like soapy water to help slide the new bushing into position. This lubricant will dry, leaving no sticky residue to attract dirt.

Torque Correctly: Reinstall the bracket and tighten the bolt to the manufacturer’s specified torque. Overtightening can crush the bushing and cause premature failure.

Chasing squeaks and replacing failed components costs time and money. At MYWAY, we engineer our high-performance polyurethane and composite sway bar bushings to provide a superior, maintenance-conscious alternative.

Our bushings are manufactured from advanced polymer blends designed for:

Optimal Stiffness: For improved handling feedback and reduced body roll compared to soft rubber.

Integrated Lubrication: Many of our performance bushings feature embedded lubricating materials or low-friction liners that are designed to last, reducing or eliminating the need for periodic re-greasing.

Durability: Resistant to ozone, road chemicals, and temperature extremes that cause rubber to crack and harden.

Precision Fit: We offer bushings for a wide range of sway bar diameters to ensure a perfect, noise-free fit.

We understand that heavy-duty trucks and performance vehicles place extreme demands on suspension components. That’s why our focus is on creating durable, reliable parts that deliver value and performance, helping you move away from the repetitive cycle of troubleshooting and temporary fixes.

6. Conclusion

The question of greasing sway bar bushings isn’t a matter of opinion—it’s a matter of material science. Greasing OEM rubber bushings is a counterproductive shortcut that leads to accelerated wear. The correct long-term solution for noisy rubber is clean replacement and proper installation.

For enthusiasts seeking an upgrade, high-quality polyurethane bushings like those from MYWAY, when installed correctly with the right lubricant, offer enhanced performance and longevity. They represent a shift from a disposable, problem-prone component to a durable, performance-oriented part of your vehicle’s suspension.

Stop guessing and start fixing it right. If you’re tired of suspension noises or want to upgrade your vehicle’s handling with components built to last, explore MYWAY’s range of engineered suspension solutions.

FAQ

Q: I already greased my rubber bushings and now they’re worse. What should I do?

A: The abrasive contamination is likely the cause. The most reliable solution is to replace the bushings. Clean the sway bar thoroughly with a degreaser before installing the new ones.

Q: How often do I need to re-grease polyurethane bushings?

A: It depends on the specific product, climate, and driving conditions. High-quality bushings with good grease can last years. A yearly inspection during maintenance is a good practice; re-grease if you see the grease has dried out or washed away.

Q: Can I use regular wheel bearing grease on polyurethane bushings?

A: It’s not recommended. Petroleum-based greases can break down and damage polyurethane over time. Always use a grease specified as safe for polyurethane, such as a dedicated poly bushing grease or a silicone-based formula.

Q: My new bushings are squeaking right after installation. What did I do wrong?

A: For polyurethane, this almost always means they were installed dry or with insufficient grease. For rubber, ensure the sway bar and bushing interior are clean and dry, and double-check that the retaining bracket bolts are torqued to specification—not over-tightened.

Q: Are there any bushings that never need lubrication?

A: Yes, certain advanced composite or self-lubricating engineered polymer bushings (like some in the MYWAY range) are designed for dry, maintenance-free operation. Always follow the manufacturer’s specific installation instructions.

100000+ Types of Bushings – Contact Us for Details