Recent Posts

The Right Bushing Match Your Heavy Equipment

Heavy equipment relies on bushings at its critical joints. Using the wrong type costs you in downtime and repairs. Here’s how to match bushing technology to three major machine types.

Table of Contents

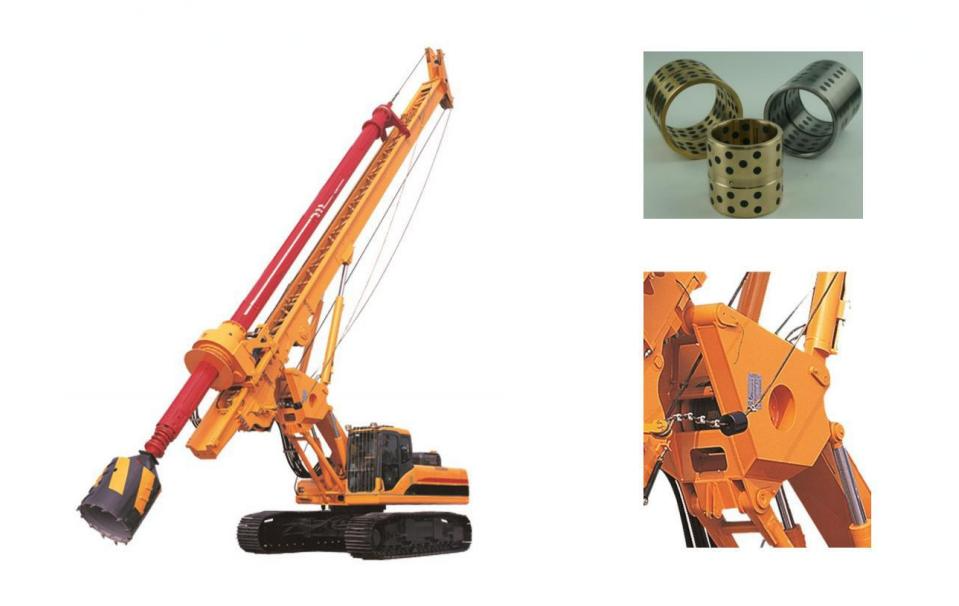

1. Rotary Drill Rigs: Solid Self-Lubricating Bushings

Challenge: High-impact vibration and contamination.

Solution: Solid Self-Lubricating Bushings with a steel backing and a PTFE/polymer layer. They work without grease, resist shock, and handle extreme pressure.

MYWAY Match: Bushings with specially formulated composites for maximum impact resistance.

2. Concrete Pump Trucks: Bimetal Bushings

Challenge: Heavy loads and constant, precise oscillation.

Solution: Self-Lubricating Bimetal Bushings. A steel backing provides strength, a copper layer dissipates heat, and a polymer top layer ensures smooth, maintenance-free operation.

MYWAY Match: High-performance bimetal bushings engineered for long life under continuous heavy loads.

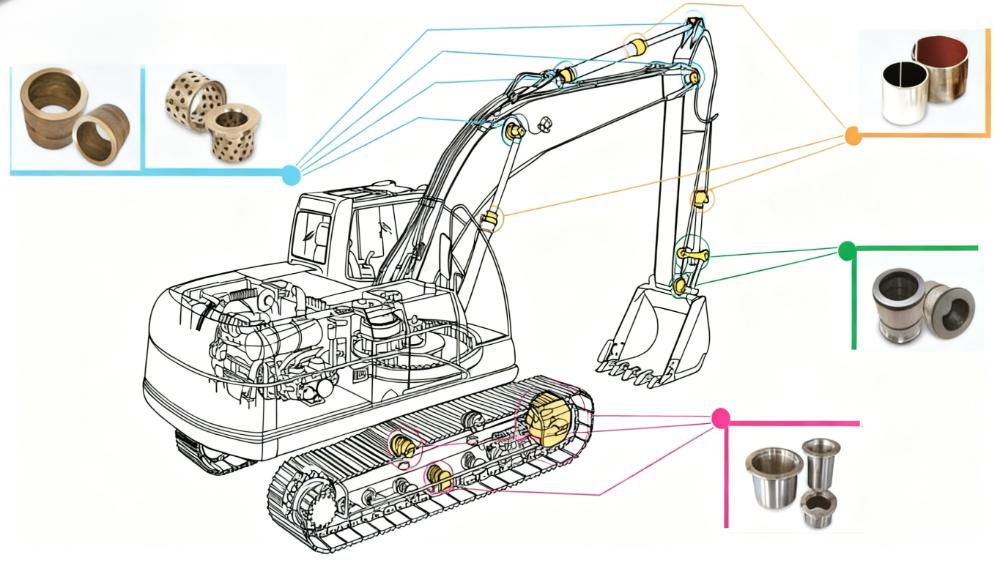

3. Excavators: The Complete Toolkit

Challenge: Diverse joints with different needs—from structural support to precise movement.

Solution:

Heavy-Duty Joints (e.g., Bucket): Steel or Bimetal Bushings for strength and impact resistance.

Precision Joints (e.g., Cylinders): DU/SF-1 Bushings for low friction and high wear resistance.

MYWAY Match: The industry’s broadest range, from super-strong steel to wear-resistant DU bushings, for every pivot point.

Expert Insight: Choosing the correct bushing technology is the easiest way to increase machine uptime and reduce long-term costs

Upgrade with Precision.

MYWAY provides the exact bushing your machine needs for maximum reliability and lower cost of ownership.Find Your Perfect Bushing Solution →

Contact Us for Expert Sizing & Quotes.

100000+ Types of Bushings – Contact Us for Details