Home » Blogs

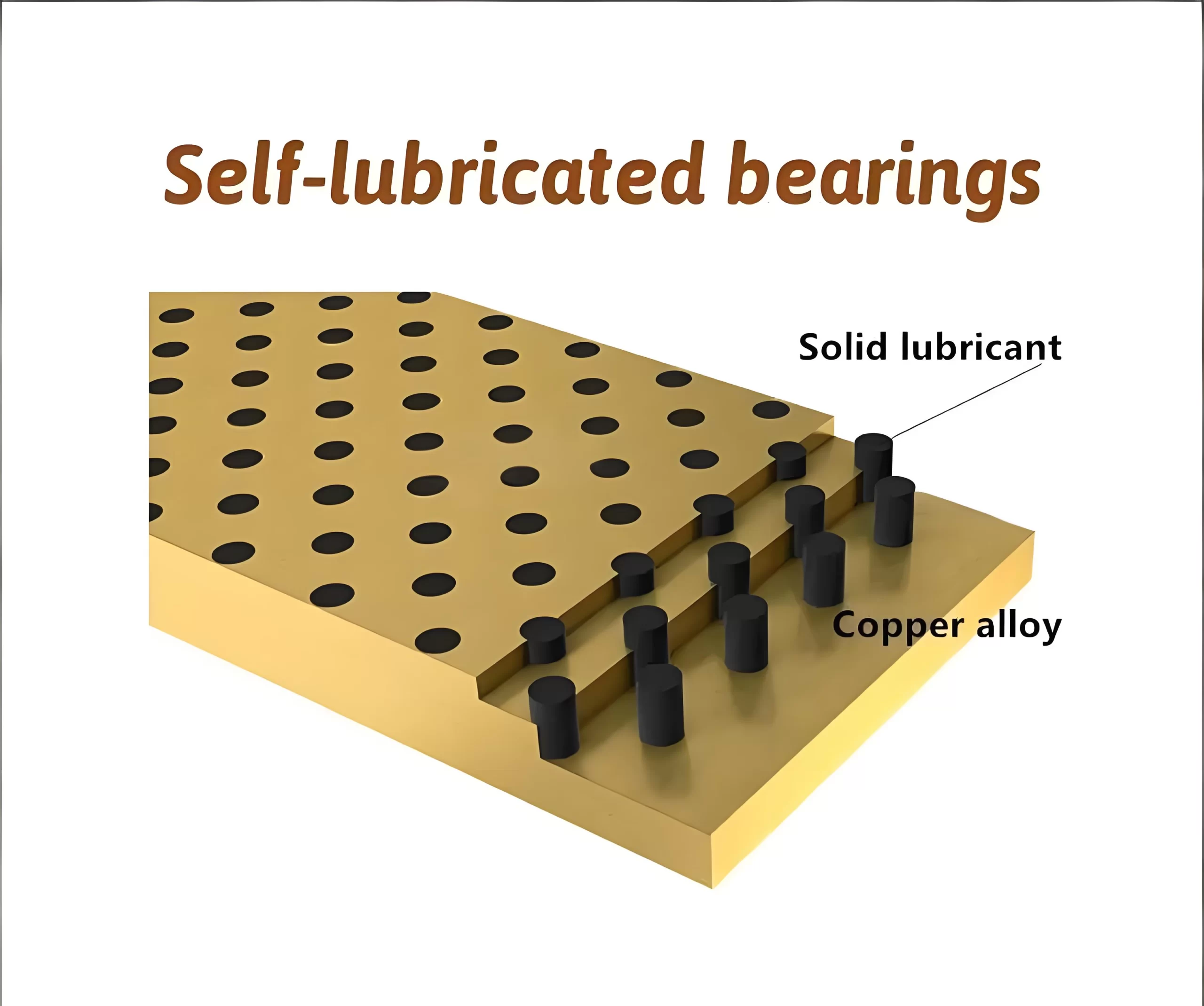

Sintered Bearings: Self-Lubricating Technology That Outlasts Conventional Metals

If you’ve ever used a power tool, driven a car, or opened a refrigerator, you’ve relied on a sintered bearing. These unassuming components are the unsung heroes of modern machinery—quietly rotating millions of times without maintenance, surviving in dusty environments where precision bearings would seize, and doing it all at a fraction of the cost of traditional alternatives.

Surface Finishes for Slide Bearing Plain Bushings: Achieving Optimal Performance and Longevity

Introduction: Why Surface Finish Deserves Your Attention

Let’s be honest—when you’re designing a mechanical system, the humble bushing doesn’t always get the spotlight. But here’s the thing: the difference between a machine that runs smoothly for years and one that fails prematurely often comes down to what’s happening at the microscopic level. Specifically, the surface finish of your slide bearing plain bushings.

Sliding Bushing Materials: Selection, Applications, and Performance Optimization

Introduction: Why Bushing Material Selection Matters

If you’ve ever dealt with machinery breakdowns or unexpected maintenance downtime, you already know the culprit often hides in plain sight—the humble bushing. These cylindrical components might look simple, but they’re doing the heavy lifting: reducing friction, absorbing shock, guiding movement, and supporting loads between moving parts .

Needle Bearing Sizes: How to Measure, Match, and Choose the Right Bearing for Your Application

Introduction: Why Size Matters in Needle Bearings

Let’s be real—nobody wants to deal with a bearing that doesn’t fit. Whether you’re maintaining heavy machinery, repairing an automotive transmission, or designing new equipment, getting the needle bearing sizes right can make the difference between smooth operation and costly downtime.

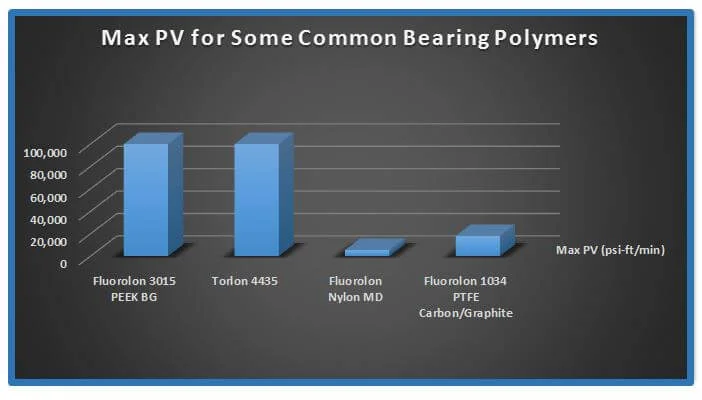

Bushing Material PV: Pressure-Velocity Ratings and Bearing Performance

If you’ve ever wondered why some bushings fail prematurely while others run smoothly for years, the answer often lies in one critical factor: PV value. Whether you’re designing heavy machinery, automotive components, or industrial equipment, understanding the relationship between pressure and velocity in bushing materials can mean the difference between optimal performance and catastrophic failure .

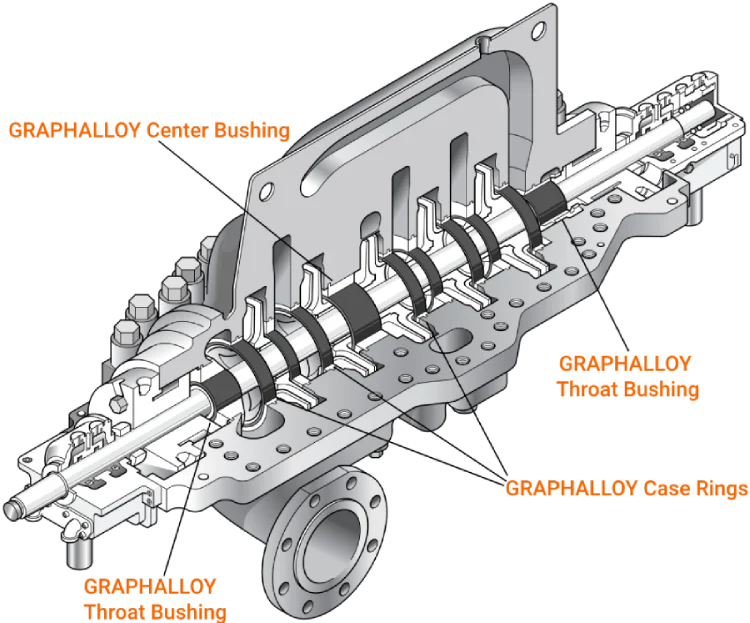

Pump Bushings: Selection, Materials, and Failure Prevention

In the world of fluid handling and hydraulic systems, the humble pump bushing is a silent workhorse. While small in size relative to the pump casing or impeller, these cylindrical components are critical for maintaining efficiency, reducing vibration, and ensuring long-term reliability. Whether you are maintaining a centrifugal pump, rebuilding a gear pump, or specifying parts for a high-pressure hydraulic system, understanding pump bushings is essential for minimizing downtime.

What Are bushes? The Engineer’s Guide to Sleeve bushes

If you work with machinery—whether you’re designing a massive rolling mill, fixing a car suspension, or maintaining a conveyor belt—you rely on a small but mighty component: the bushing.

The Heart of Renewable Energy: High-Performance Bearings for Hydropower Plants

In the global push for Net Zero, hydropower remains the unsung heavyweight champion of renewable energy. While solar and wind grab headlines, hydro provides the stable, on-demand baseload power that grids desperately need. According to the latest data, hydropower accounts for a significant portion of clean energy generation, with major players like India housing nearly 200 operational hydropower plants .

Why Heavy-Duty Applications Rely on Spherical Plain Bearings: Self-Lubricating, Maintenance-Free, and Built to Last

If you work with construction machinery, mining equipment, marine systems, or even hydropower infrastructure, you already know this truth: the joints wear out first.

Cylinder clevises. Hydraulic pivots. Gate hinges. Swing linkages.

These are the spots where misalignment happens, where shock loads hit hardest, and where maintenance access is usually a nightmare.

Slide Plates: What Engineers Get Wrong About Self-Lubricating Bronze

If you design dies, specify mould components, or maintain heavy machinery, you’ve spec’d slide plates a hundred times.

But here’s the uncomfortable truth: most engineers still treat slide plates as “just wear strips.” They pick whatever bronze stock is cheapest, drill a few holes, and hope the graphite plugs do their job.

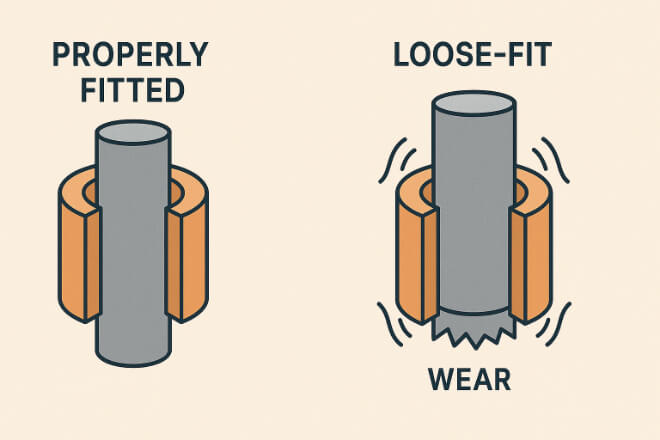

Press Fit Tolerancing for Bushings: The Engineer’s Guide to Secure, Long-Lasting Performance

A precisely toleranced press fit is the silent guardian of mechanical integrity, transforming a simple bushing into a permanent, load-bearing component of your assembly. In the world of rotating and sliding components, the difference between smooth operation and catastrophic failure often hinges on the microscopic space—or intentional lack thereof—between a bushing and its housing.

Beyond the Round: How Special Shape Bushings Solve Your Toughest Engineering Challenges

In the world of machinery and motion, the space between “it works” and “it works flawlessly” is often defined by a critical, yet frequently overlooked component: the bushing. While standard round bushings serve countless applications, engineers constantly face a harsh reality—not every shaft, pivot, or linkage fits neatly into a perfect circle.